When I made my first trip to Cambodia in February 2016, some of my colleagues with more experience in the country were skeptical. At the DAI Maker Lab, my job is to build hardware and capacities around creating hardware in support of foreign aid projects. Cambodia, I was told, might not be ready: the manufacturing sector is not well-developed, and the human resource base is still recovering from tragic recent history. Two years and several visits later, however, it is apparent that not only is Cambodia a good place to apply the new tools and approaches of hardware production, in some ways this is true because of the country’s challenges. And blossoming talent and interest are now beginning to appear offer exciting hints of a brighter future.

As makers, we are familiar with how access to the new generation of digital fabrication tools and microcontroller platforms empower us as individuals or communities to produce things that we used to think of as requiring factories and professional engineers. In places like Cambodia that are far from more traditional manufacturing infrastructure, this new road to hardware offers exciting opportunities to attack previously unaddressed problems.

Tepmachcha

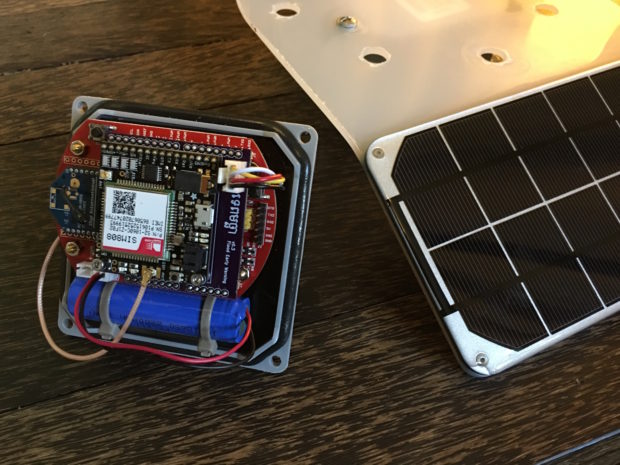

In mid-2016 I worked with an NGO called People In Need (PIN) to develop and pilot Tepmachcha, an open source early warning flood detection system. Its name originates from early Cambodian history and mythology; particularly the tale of the god Vishnu appearing in the form of a fish to warn mankind of a catastrophic flood. This fish avatar, known in Sanskrit as “Matsya“, is called “Tepmachcha” in Khmer, and is the namesake of the project.

Mounted on the side of a bridge, Tepmachcha senses the level of the water beneath, and uses the mobile phone network to send that data to a cloud-based server. Should the water height reach a dangerous level, Tepmachcha triggers PIN’s interactive voice response (IVR) system – an automated telephone system – to make a voice telephone call to thousands of affected residents within a matter of minutes. SMS alerts would likely be less effective in the Cambodian context; in addition to literacy issues one finds in rural areas, many phones do not render the Khmer character set correctly. No manufacturer makes a sonar stream gauge that interacts with a RapidPro IVR system’s API – the need is far too specific to represent a viable market for a mass-produced product – but with the new generation of tools, we can build such a device for less than US$300 worth of parts.

After we piloted the first two units, PIN has gone on to engage a local small company, Bespokh, to improve the hardware and software and build more units – fifteen are expected to be in place by the end of this year.

Green shoots

Bespokh is just one of the emerging local providers that is building hardware to meet Cambodian needs. Angkor E&C offers custom electronics design and implementation services, as well as more sophisticated configuration and programming for industrial clients. In addition to their custom work, they have a car and motorbike tracking product they offer on the local market. Fewer than 100 have been sold to date, but the economics of a small Cambodian company are quite different from those of a full-scale manufacturer, and the new fabrication methods do not require the same large markets and audiences that traditional businesses need.

In a modern office space near Orussey Market, ArrowDot offers specialized courses on electronics, along with an impressive retail space offering boards, components, and other accessories for working with electronics. In addition to training, ArrowDot offers custom electronics design services for local clients – “smart building” projects are popular.

If evidence is needed of the topsy-turvy state of the economics of production, it can be found emerging layer-by-layer on a battery of 3D printers in ArrowDot’s central workspace: connectors for DoyDoy, a locally designed and produced STEM toy. DoyDoy lets kids build structures with silicone tubing easily fastened with the 3D printed connectors. DoyDoy’s creator, Em Chanrithykol, looked for injection molding providers to make the connectors, but could find none locally and could not afford the large runs necessary to get them made elsewhere in the region. 3D printing is generally considered to be a prototyping rather than a production technology, but because of the size and dynamics of the Cambodian market, DoyDoy contracts with ArrowDot to 3D print the parts and makes it work at $13 a box – less than a starter Strawbees kit – a similar product that originates in Sweden.

Fuses and fused filament

DoyDoy is not the only exciting 3D printing story in Cambodia. On my first visit to the country in 2016, I met with Allen Dodgson Tan from Golden West Humanitarian Foundation. Golden West works to combat the dangers of landmines and other unexploded ordnance, of which Cambodia sadly has a great deal. One of the ways Golden West does this is by creating training materials for mine clearance workers. While they are now working on virtual reality and augmented reality tools, their 3D printed ordnance models are still the most impressive to me. 3D printing enables them to produce accurate models of ordnance that are several times larger than actual size or include interactive mechanisms and cross sections to show how the active structures work. Being able to physically interact with these mechanisms gives trainees an intuitive understanding they could not obtain from static materials.

The worldwide market for such models is small – Tan estimates they have sold about 60 full kits and numerous single models – and so 3D printing is really the only fabrication technique that makes economic sense. When I first saw this in 2016, it struck me as the best application of 3D printing to a problem that I had ever seen. It still does. But it is a story that for some reason is little known outside Cambodia.

Make local

Next door to ArrowDot is TRYBE, which bills itself as Cambodia’s only makerspace. While this status could be debated, the closure of the greatly missed Hackerspace Phnom Penh has left few other places to get access to digital fabrication tools. Located within TRYBE, ARC Hub PNH offers design and 3D printing services. Working with other design and implementation talent from around the local community, in 2016 TRYBE and ARC Hub PNH hosted Think Global Make Local, an eight-week course on product development intended to create a cohort of young Cambodian designers and entrepreneurs with the confidence and ability to take their ideas from conception to market.

Ten participants chosen through an application and interview process developed a product idea, learned some 3D design and digital fabrication techniques to prototype and iterate it, and developed some basic business skills. DoyDoy is a TGML alum, as are Akara, a laser-cut acrylic stencil of Khmer characters intended to help with literacy education, and My Dream Home, an interlocking concrete brick product that can be readily produced from local molds.

Making the Future

So the beginnings of a hardware innovation ecosystem can be seen in Cambodia. There are proven markets – both commercial markets and markets for public service applications – and there are opportunities that would not work in a developed country context. How can we take advantage of these opportunities?

- Cataloging the manufacturing gap. The Cambodian manufacturing sector is underdeveloped and stratified – small-scale production works by word-of-mouth networks; large-scale production is limited to textiles or to foreign companies that bring in their own capital for the purpose. Cambodian innovators need a guide to what manufacturing is available locally so they can access the capabilities that exist and build businesses around the ones that do not. Doy Doy connectors are small and do not require too much precision; if the injection molding to manufacture them does not exist in Cambodia, that is a market opportunity open for a small entrepreneur.

- Promoting local production. I find that aspiring hardware producers everywhere – not just in Cambodia – tend to think in traditional terms when conceptualizing how to solve problems and make a livelihood with hardware: design, prototype, and mass-manufacture. But in Cambodia and other developing countries, the barriers to manufacturing are higher, and the economics of scale (which refers to the savings related to increasing the size of production) are markedly different. Doy Doy’s 3D-printed connectors and Angkor E&C’s vehicle tracking demonstrate that the new fabrication tools and approaches pave the way to a new model of hardware production. The more Cambodian innovators get this message, the more opportunities they will create.

- Building community. While the Cambodian hardware community is small, it is not as closely networked as it could be. A deliberate effort to build a stronger community could disseminate key ideas and spark important collaborations. A regular hardware meetup, with compelling presentations and learning opportunities, would not be difficult to arrange and could help build that community.

Come see Rob give a talk on getting started with LoRa and LoRaWAN at World Maker Faire New York coming up the weekend of September 22 and 23rd. Get your tickets now!

ADVERTISEMENT