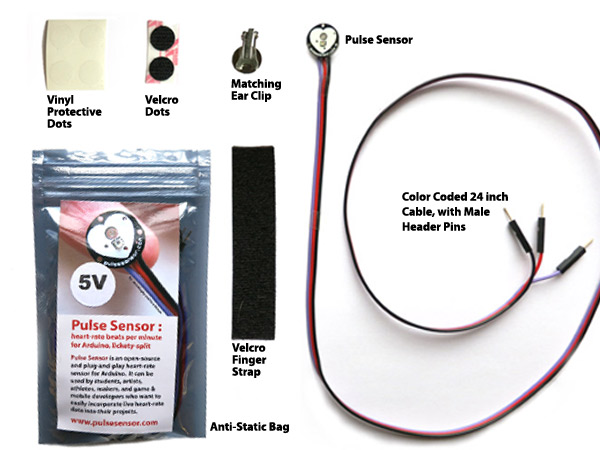

The Pulse Sensor Kit is a kit. It does contain an assembled PCB Pulse Sensor, but it also has a collection of other supplies that you need to get the most out of the Pulse Sensor: a Velcro strap (to wrap the sensor around your finger), an ear clip, and vinyl dots (to make the sensor more comfortable and reliable when contacting direct skin). It doesn’t sound like a lot, but using these helps you get good long-term readings. Unless you are a seamstress or jewelry designer, these parts are not exactly effortless to source. We tested a lot of Velcro straps and ear clips before selecting the ones that finally made it into our kit.

The PCBs are made overseas, for the most part, when nothing goes wrong. But the rest of this kit is assembled by our hands, into a nicely compacted form. I’ve always loved time-lapse videos, so I made a video of us assembling about 800 kits to go out into the world.

We have the technology (to quote The Six Million Dollar Man), but commercial tools for exploring, assisting, and augmenting our bodies really can approach a price tag of $6 million. Medical and assistive tech manufacturers must pay not just for R&D, but for expensive clinical trials, regulatory compliance, and liability — and doesn’t help with low pricing that these devices are typically paid for through insurance, rather than purchased directly. But many gadgets that restore people’s abilities or enable new “superpowers” are surprisingly easy to make, and for tiny fractions of the costs of off-the-shelf equivalents. MAKE Volume 29, the “DIY Superhuman” issue, explains how.

ADVERTISEMENT