Dewalt’s DWS780 saw (Dewalt) is a 12-inch double bevel sliding compound miter saw. A miter saw makes quick work of crosscuts in wood, and with the appropriate blades it can be used to cut plastic and (certain types of) aluminum materials.

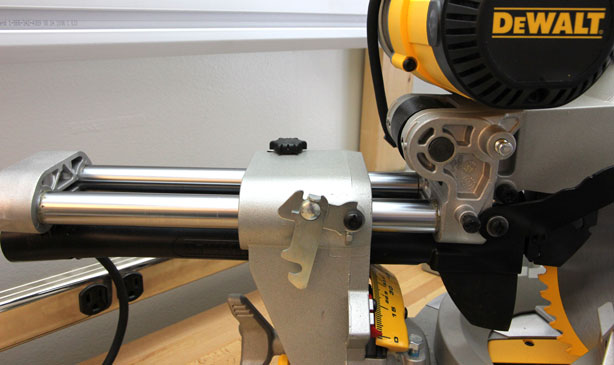

The DWS780 can be adjusted to cut horizontal (miter) and vertical (bevel) angles at the same time, allowing users to make complex cuts with a single operation. The sliding mechanism greatly increases the cutting width compared to non-sliding saws.

This is one fine beast of a machine with a lot of parts and features. So before I get to what I did and didn’t like about it, following is a breakdown of its major features and adjustments.

Note: The photos below show the saw resting on a benchtop. In-use, the saw should be bolted down to a fixed surface or secured to a miter saw stand.

Cut Capacity

At the 0° setting, the DWS780 can cut boards up to 13.75″ wide and 4.4″ thick. If you use the “back fence,” you can straight-cut up to 16″ wide boards. But such cutting capacity is not without its disadvantage. As with other sliding miter saws, the DWS780 requires a fair bit of space behind it for the rails to slide properly.

Miter Adjustment

There are positive locks at all the common miter angles, and an override (the small black lever to left of the miter latch button and lock handle) allows you to set the angle to any value you desire.

Bevel Adjustment

The DWS780 saw is a double bevel model, meaning that it can tilt to the right or left, which makes it easier to cut complex angles such as for crown molding and tapered boxes.

On each side there are two fold-away pawls that provide bevel stops of 22.5° and 33.9°. (33.9° is used with a 31.6° miter setting to cut molding for 90° joints.) There is also a 45° override (the silver-colored lever on the bottom) that allows you to adjust the bevel angle slightly past this value in either direction.

At the rear of the saw, the 3-wing knob is used to loosen and lock the bevel adjustment. The yellow cam-action switch is a 0° bevel stop that must be pulled out or rotated to enable the saw to bevel to the right.

Depth Stop

A depth stop, which consists of a depth adjustment screw, wingnut, and the stop itself, can be used to limit the cutting depth of the blade to provide much more control for cutting grooves and taller workpieces.

XPS Work Light

Dewalt’s XPS work light casts a shadow of the saw blade onto your workpiece to help align your cut-line with the blade. As I mentioned before, I found the XPS light to perform far better than any laser as it requires no alignment and will always cast a shadow of the exact width of your saw blade’s kerf, or thickness.

In comparison, a laser alignment system projects a laser line that will always be the same width regardless of the thickness of your blade, requiring a bit of trial and error to set things up perfectly.

Dust Collection

Dewalt claims that their dust collection chute can collect over 75% of dust generated. Even if these claims are true, 20-25% of dust and chips is still a lot, so heavy users will want to invest in a shop vacuum, dust collector, or barrier system to help contain the mess.

The included dust bag is itty-bitty, but if it were any larger the saw would require even more rear clearance.

Blade and Accessories

Dewalt bundles the DWS780 with a 12-inch 60-tooth fine finish blade. This is a decent starter wood-cutting blade – which actually performed better than expected – but it’s still designed for general construction tasks and not fine woodworking. It’s not necessary to spring for a better blade right away, but premium blades will often provide cleaner cuts. It is also recommended that users match blades to the types of materials they plan on cutting.

Dewalt includes a robust hold-down clamp with the saw. There are no outfeed supports included, however, which is understandable since many users will use the saw with portable or stationary stands.

Portability and Size

There is a handle at the top of the saw, and two (more practical) hand grooves at both sides of the saw. The saw weighs in at 56-pounds, so while it is portable, it is not a joy to move around all day.

The DWS780 provides MUCH more functionality and cutting capacity than a non-sliding 10-inch saw, such as Dewalt’s DW713 saw (left). But you can also see how much larger its footprint is. The DWS780 is also quite a bit pricier ($600 vs. $219).

Performance, Precision, and Conclusion

I was happy to find that all of the knobs, levels, and adjustments were easy to access and comfortable to use. The function of each control is easy to figure out, but everything is still clearly documented in the instruction manual (PDF).

Out of the box, everything was perfectly aligned. Cheaper homeowner- and DIY-oriented saws often require a bit of adjustment and tweaking to get the fences, miter angle, bevel angle, and the blade all zeroed and where they should be. It’s always nice to be able to unbox a new tool and put it to work right away.

I used the saw to to cut wood studs, 2.5″ thick hardwood strips, shelving material, and 3/4″ plywood with no trouble at all. I trust its ability to cut thicker wood materials, PVC, plastic sheets, and aluminum extrusions, but have not gotten around to picking up the proper 12-inch blades yet. The motor is rated at 15A and 3,800 RPM.

Like other sliding miter saws, the DWS780 requires quite a bit of space around it. When not in use, it does fold down and rotates into a fairly compact and shelvable package. But for very regular use and permanent shop placement, the more compact Bosch Axial Glide miter saw (preview) provides tough competition.

Overall, the DWS780 12-inch sliding miter saw proved to be a stellar model. The saw cuts well and precisely, it adjusts quickly and comfortably, it slides smoothly and near effortlessly, and the XPS work light is a really appreciated feature.

Stuart Deutsch is a tool enthusiast, critic, and collector, and writes his passion at ToolGuyd.

ADVERTISEMENT