Lamp3D is a small, repositionable, gooseneck-style LED lamp. It’s a fun and easy introductory project for those just starting out with 3D printing, electronics, and soldering.

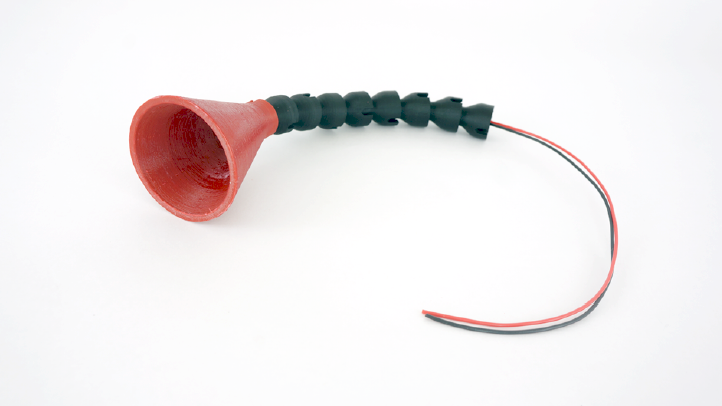

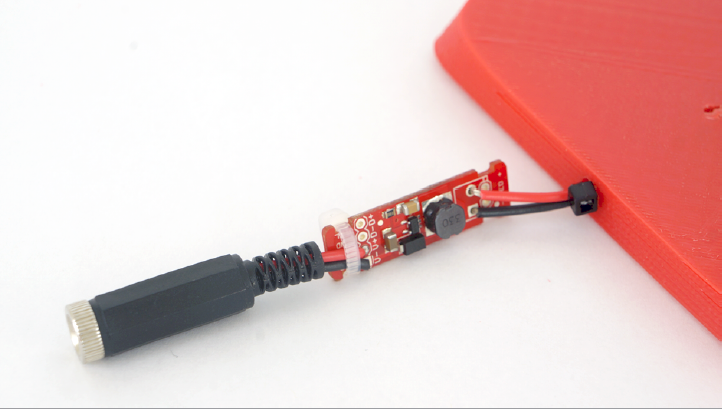

The minimalistic design of this lamp was inspired by the Loc-Line modular hose/pipe system that’s been used for everything from CNC machine lubrication to flexible shower heads. All of the lamp’s structural components are 3D printed, with no additional hardware required.

It can be easily customized by adding more linkages (or “vertebrae”) or by modifying the lampshade. Plus, we can fabricate it on a very small print bed.

Be sure to get your tools, materials, and files sorted before embarking on this fun project. All the files and code for each of the projects in the book is available from the Make: 3D Printing Projects GitHub site.

Here are the 3D printable files you’ll need to get started:

Quantity Description Filename

1 Lamp Base (ABS or PLA) Base.stl

1 Lamp shade (ABS) LampShade.stl

9+ Vertebrae (ABS) Vertebrae.stl