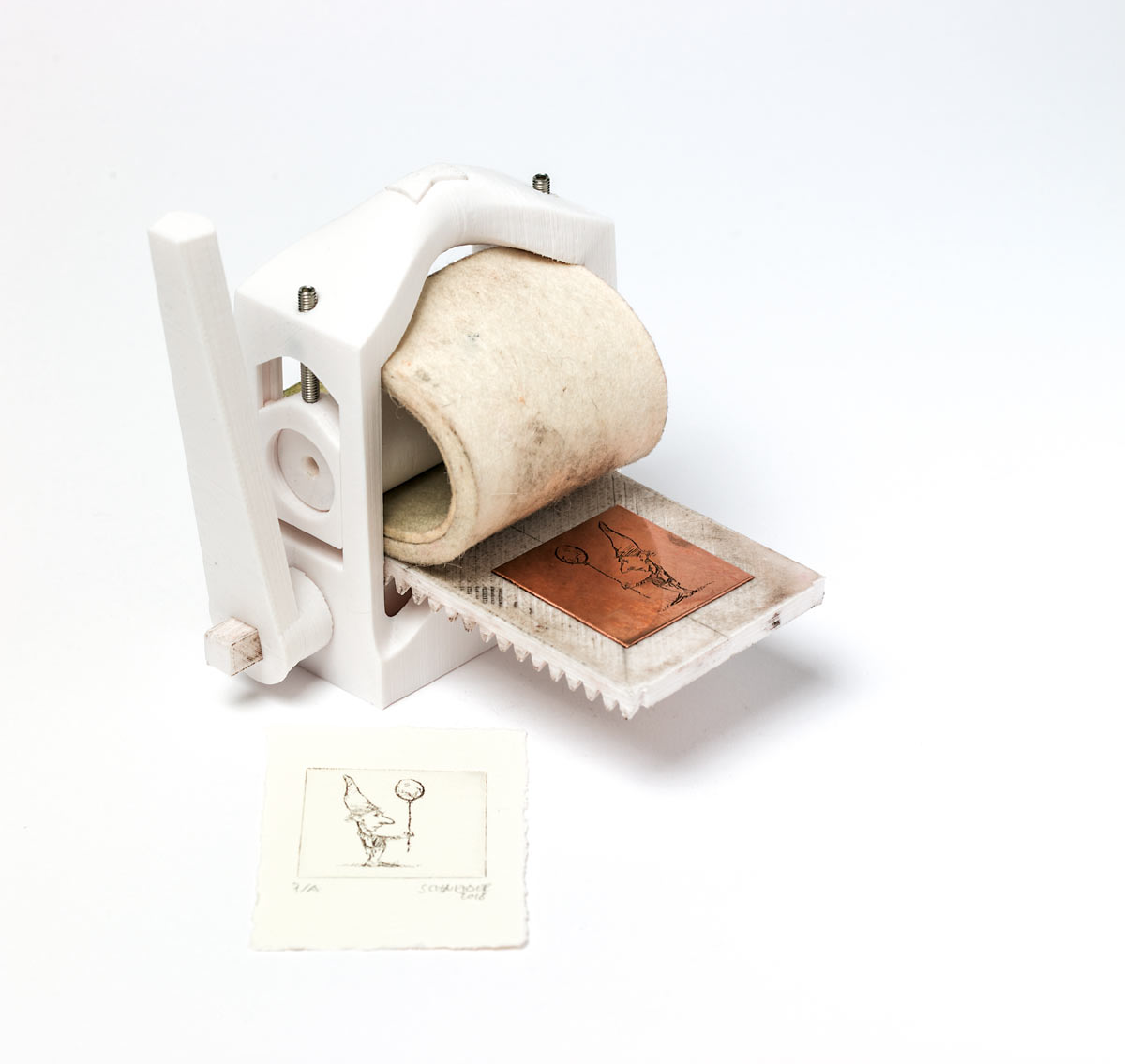

Get a taste of traditional printmaking with the world’s first 3D-printed etching press! With the help of 3D printing, these unique art techniques are finally accessible to a lot more people, and in places where printmaking wasn’t possible before.

Printmaking has been around for 500 years, used for illustrating books, printing banknotes, and duplicating famous paintings. Today, printmaking is known for its distinct look and is used by artists around the world, but lots of people don’t have access to printmaking due to the high costs of a press. Etching presses for intaglio printing are especially hard to find due to the high amount of pressure that’s needed.

So I designed a working press that can be produced with a 3D printer: the Open Press Project . The 3D files are free to use, and the project has already grown into a small community of excited makers and printmakers all over the world!

Get In the Grooves

I like to explain intaglio printing technique in comparison to relief printing, because everybody knows how potato prints and rubber stamps work: In relief printing, the raised surfaces of the stamp or plate are covered with ink while the grooves remain un-inked. With intaglio printing it’s the exact opposite: We carve scratches and grooves into a plate and fill them with ink. Then we remove the ink from the surface, so that it remains only in the grooves. The paper is then compressed into the grooves to pick up the ink.

Keep It Rolling

Now that you’re a printmaker, there’s much more to explore. For your intaglio plates, you can use all kinds of materials including copper, zinc, aluminum, steel, plastics, CDs and linoleum, wood, and foam board. I’m using copper most of the time, though for beginners it’s less expensive to practice on juice boxes or CDs.

Your press can also be used for relief printing techniques like linocuts, woodcuts, and 3D-printed plates, and for mixed-media colligraphy, which can be printed intaglio or relief.

I would love to welcome more makers to our Open Press Project community on Instagram. Please share your presses and prints, it would make my day!

I would also love to see your redesigns, adjustments, and improvements to the press itself. After more than 300 years of non-existing innovation in the design of a printing press, it’s time to take it to the next level! All of the STL files are licensed under the Creative Commons Attribution-NonCommercial 4.0 International License, so you’re free to copy, share, and edit the press for non-commercial purposes.

Questions or feedback? Email me at martinschneiderart@gmail.com. I would love to hear from you!