This is one of the great projects featured this summer in our 2017 Maker Camp — Navigate there to find even more fun things to build, join a camp, share your projects, and more!

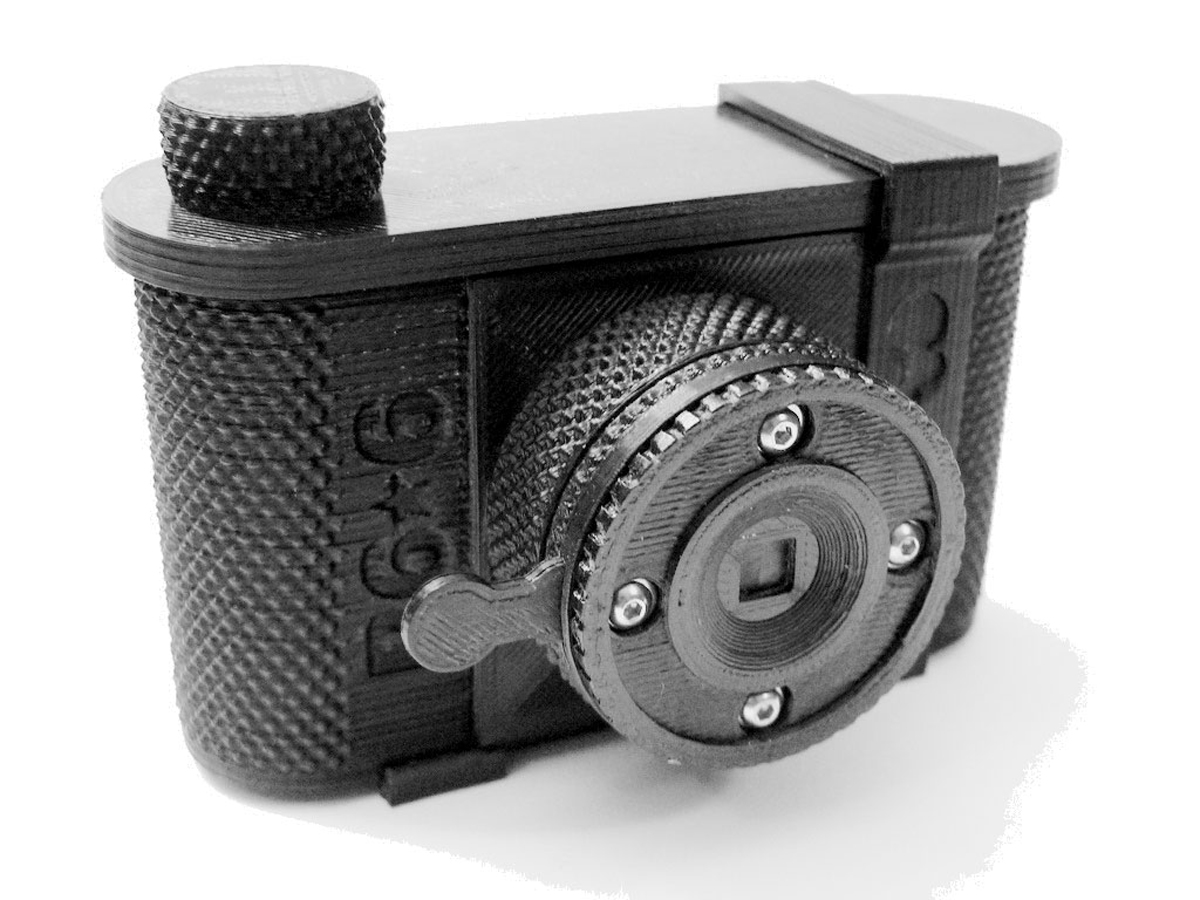

The P6*6 is a 3D-printed pinhole camera, glued and fastened together with 3mm nuts and bolts. All of the individual parts print without support and fit on a 6-inch square print bed. The files are available for download from Thingiverse.

The P6*6 comes in two focal lengths, 35mm and 50mm. It uses 120 roll film and makes an impressive 6cm square negative — roughly 4 times larger than a negative from a standard 35mm camera. 120 film is widely available and can be found at camera stores that cater to professional photographers or from internet vendors.

P6*6 Specs:

- 120 film, 6×6 format

- 50mm focal length:

- f-stop of f/167 with 0.30mm pinhole

- 62 degree vertical and horizontal angles of view

- 35mm focal length:

- f-stop of f/135 with 0.26mm pinhole

- 77.4 degree vertical and horizontal angles of view

BONUS: Check the last step in this project for new, optional accessories you can print!