Several hundred million electric toothbrushes are manufactured, and sadly discarded, each year yet most people don’t realize that toothbrush parts are salvageable and they don’t have to wind up in a landfill or the ocean.

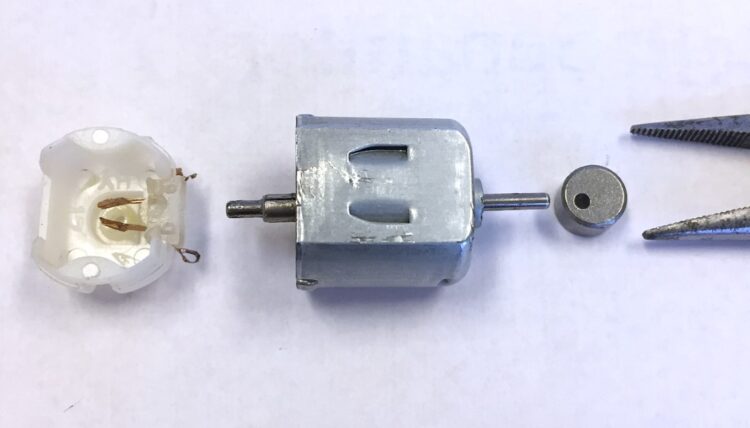

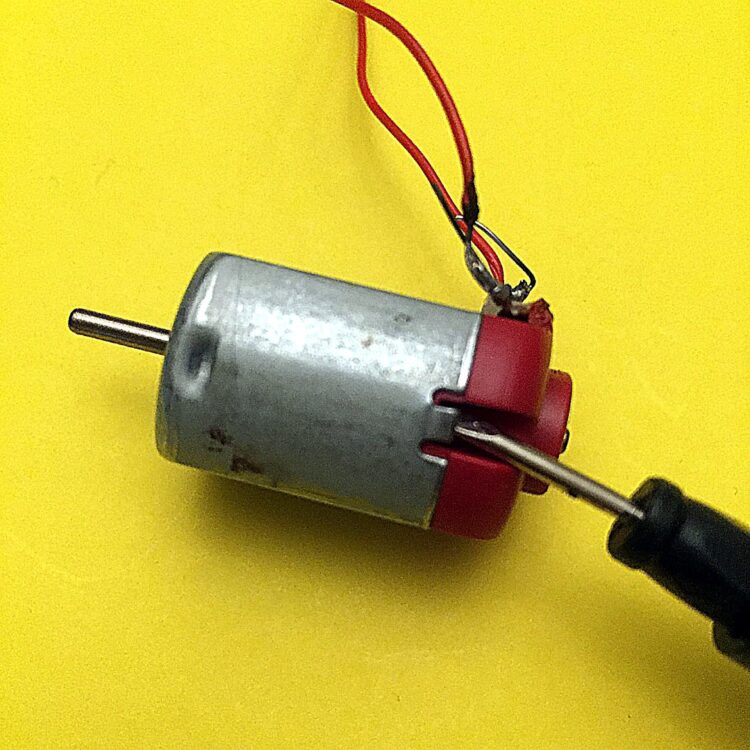

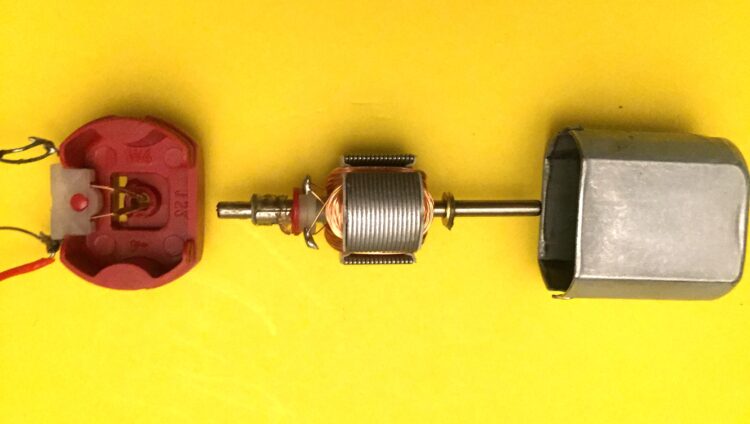

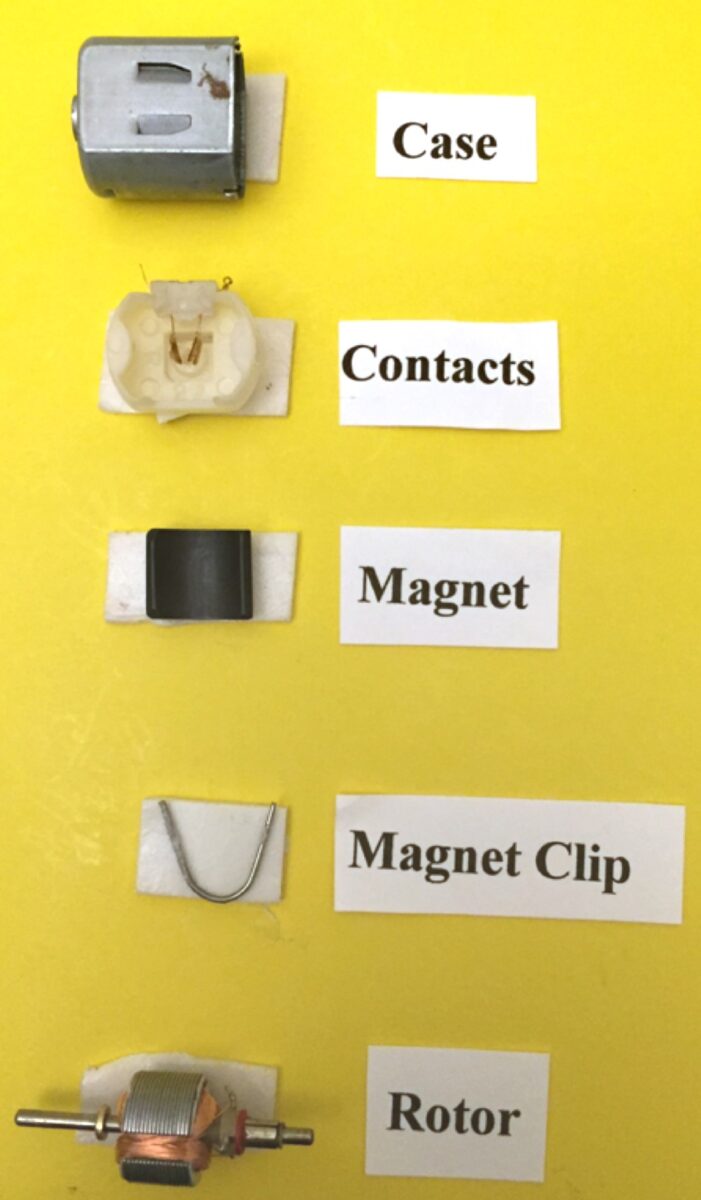

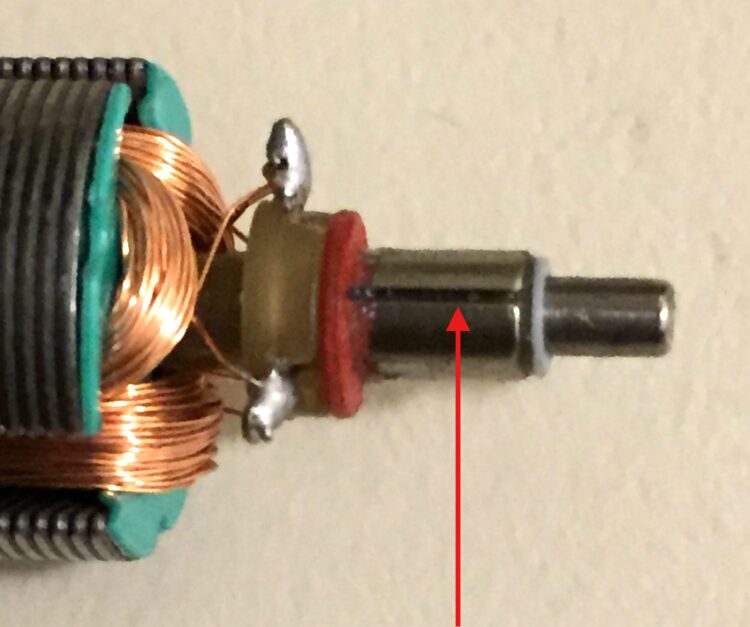

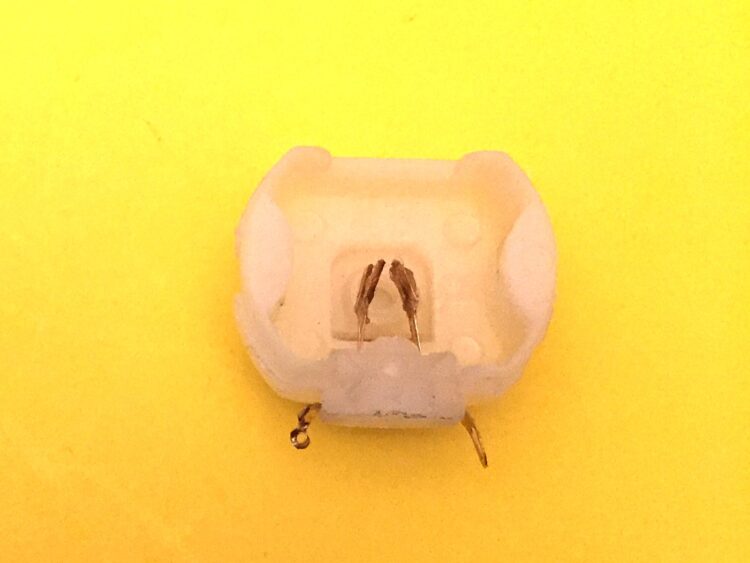

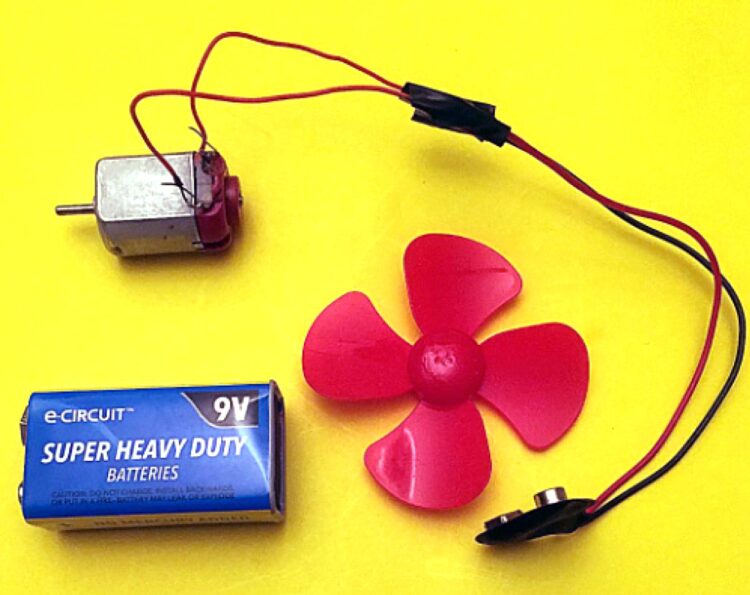

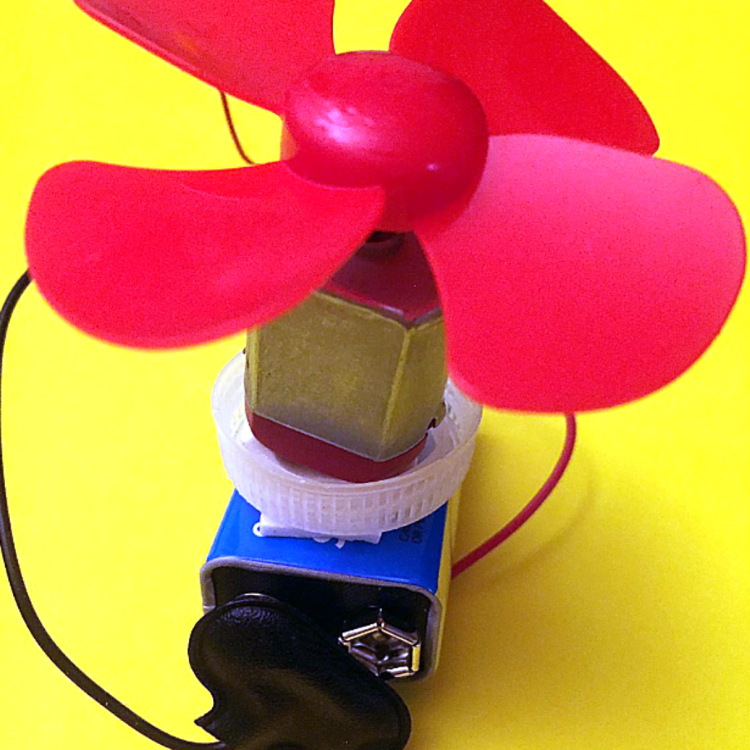

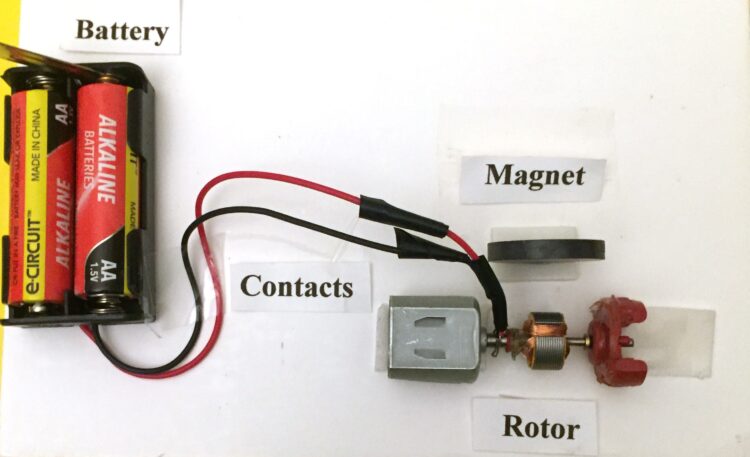

Using the magnets and motors inside discarded electric toothbrushes — and also inside motorized personal fans, pencil sharpeners, fabric shavers, facial brushes, and toy cars — I’ll show you how to repurpose them to make 10 practical projects. Here in Part 1 we’ll build five using motors, and in Part 2 we’ll build five using magnets!