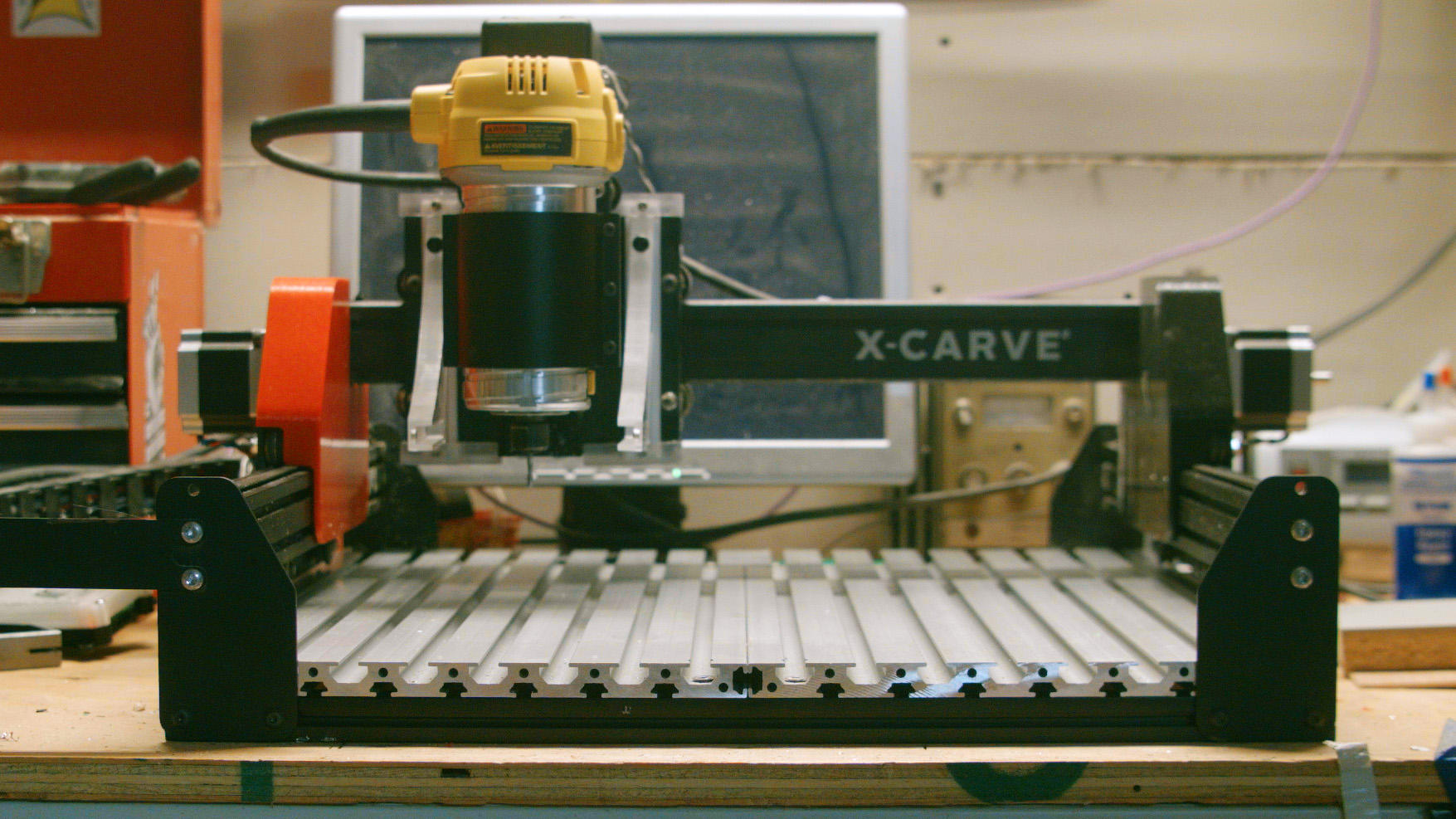

The X-Carve from Inventables is a fantastic entry point into CNC Routing – it is a low cost, highly capable machine with some really accessible software. However, workholding has always been a constant frustration for me in regards to this machine. My stock spoilboard was not level to the router, so I had to mill it flat in order to have a useable work surface, and the threaded inserts were always spaced a little too far apart to be of any real use to me. I have always envied the T-slot beds that are commonly found in CNC mills for the large amount of flexibility they offered in holding your work down.

Misumi makes an aluminum T-slot extrusion that measures 250mm x 500mm. Two of these, side by side, should be a near drop-in replacement for the stock spoilboard. My plan was to drill some 5mm holes into the edges of the extrusions, and then use these to mount them to the 2020 rails that make up the X-Carve’s frame. It did not quite go exactly to plan – I had to carve out a little bit of material so that my screw heads would fit down into the slots and re-assemble the gantry in a specific way to make sure that the lower y-Axis V-Wheels had enough clearance to roll freely.

This is a fairly low-cost modification to make to the X-Carve and, so far, I am extremely happy with it. It has taken nearly every workholding headache out of my process. The new bed has overall improved the rigidity of the machine and the spindle is now consistently square to the bed.