The super-loud Boom Stick is a PVC air cannon that delivers maximum bang for the buck. It assaults the startle reflex of any nearby victim, adding an instant rush of physical terror to haunted houses, art pieces, pranks, and performances.

I work in haunted houses during the Halloween season, as an actor, guide, technician, makeup artist, and effects creator. Some of my effects instill fear through foreshadowing or complex storylines, but the most effective way to scare people is often just a simple, brute-force startle.

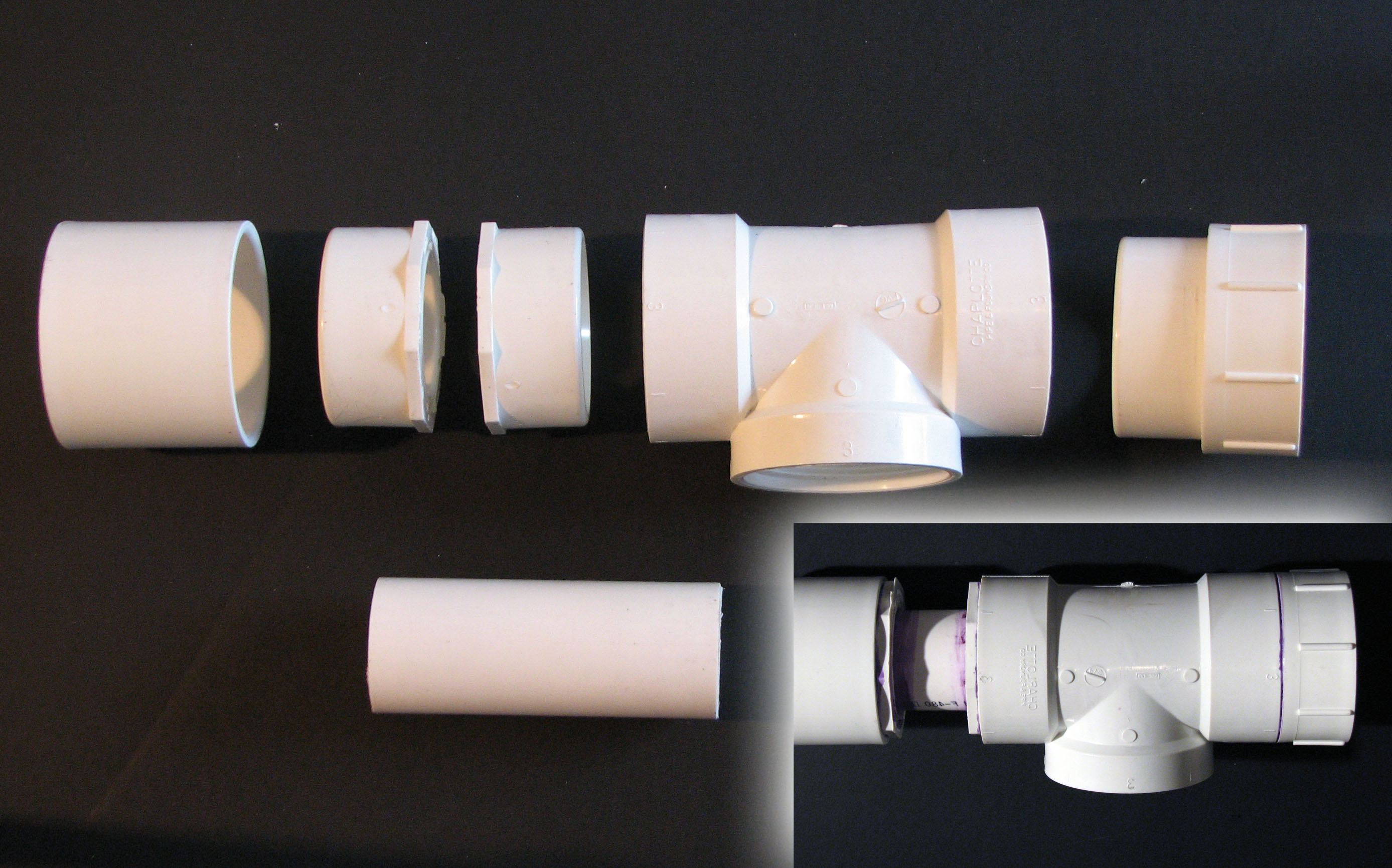

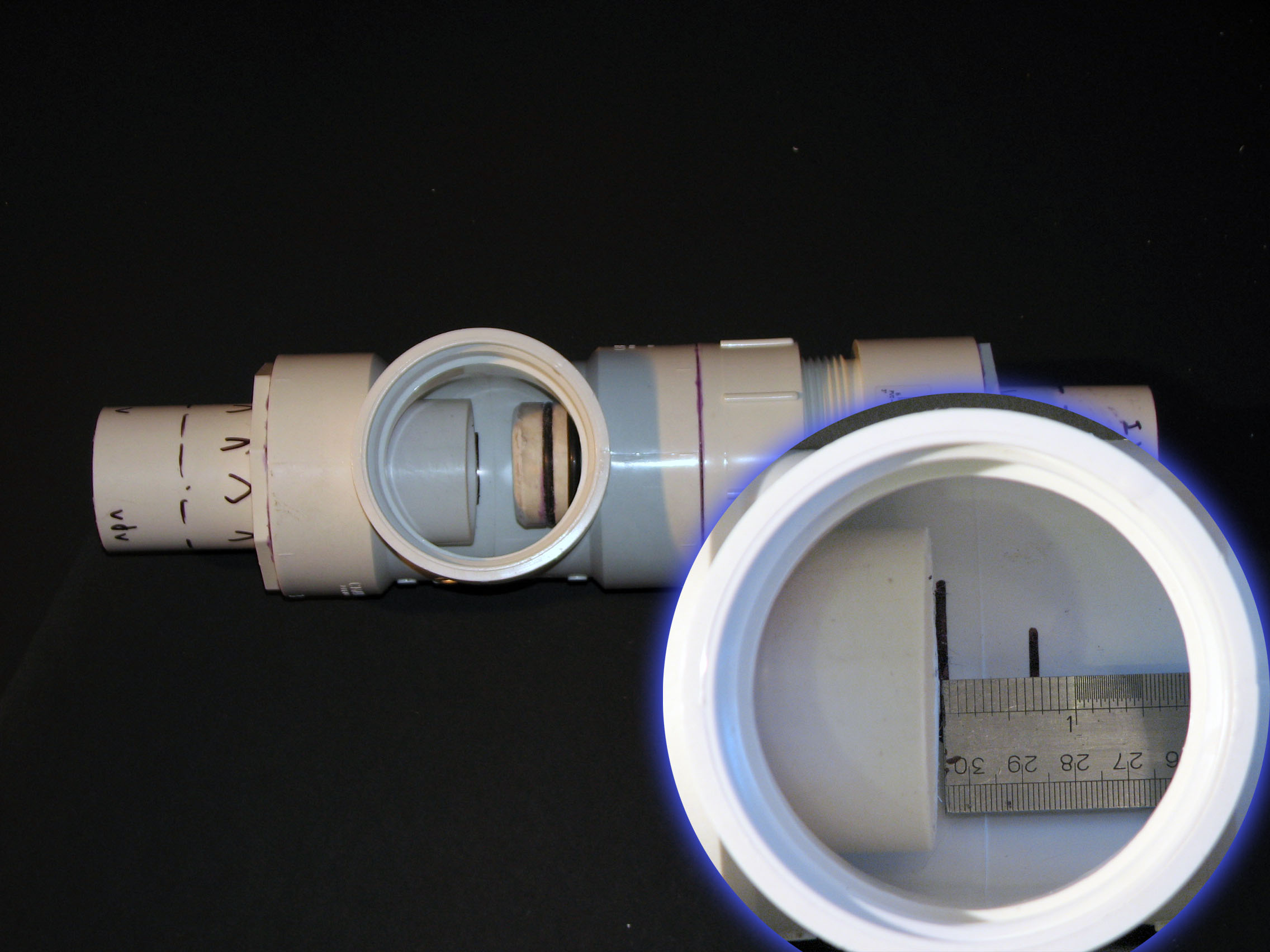

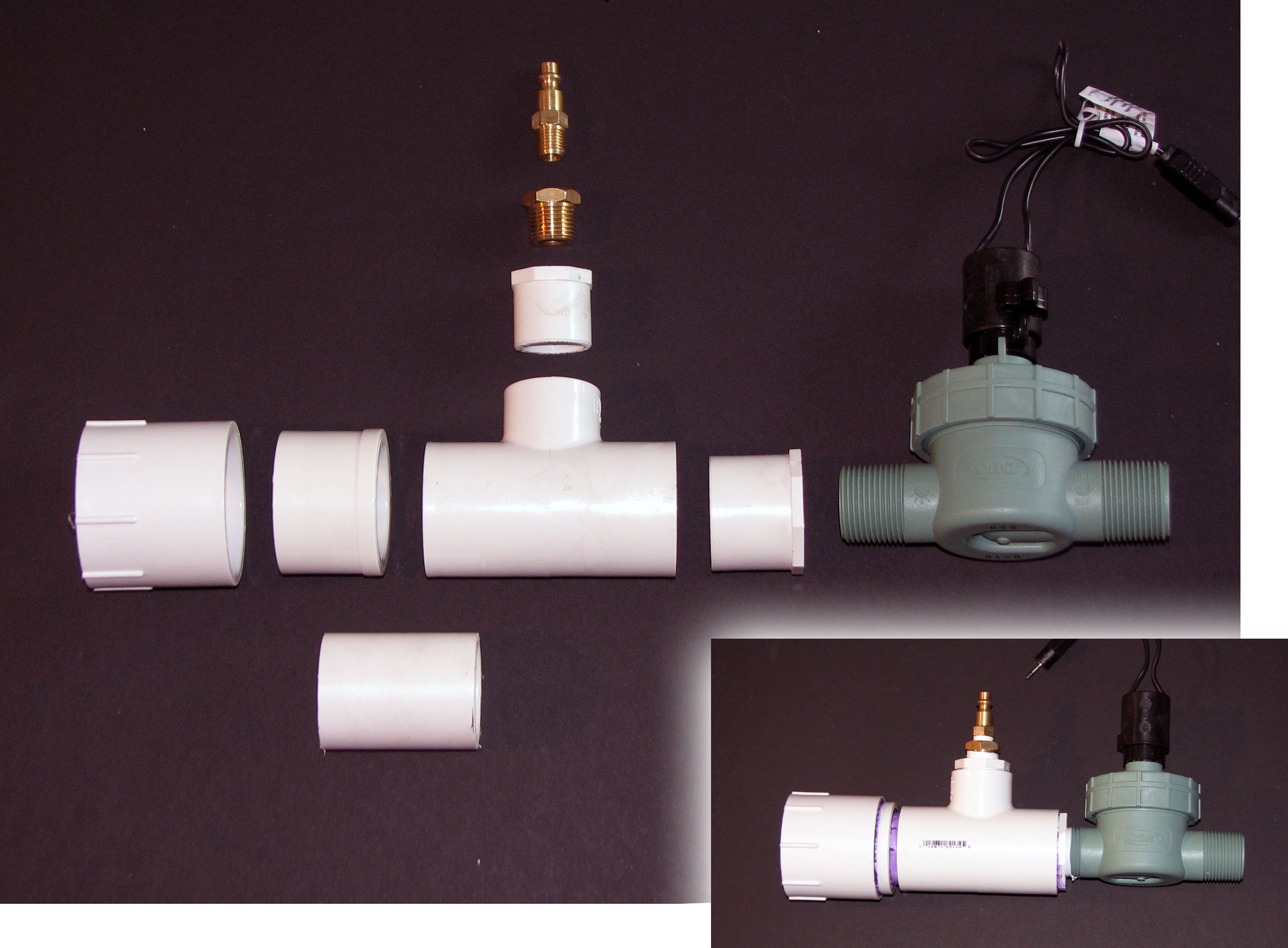

The air cannon is a great and safe device for such scares. In its simplest form, it consists of an air reservoir, a quick-exhaust valve (QEV), and sometimes a resonating chamber. Haunted house suppliers and special-effects houses sell commercial models with large-gauge QEVs, but these cost hundreds of dollars. Home projects that rely on a standard air compressor typically use smaller, cheaper water valves from washing machines or sprinklers, but for me, these designs have yielded only a disappointing “poof-hiss.”

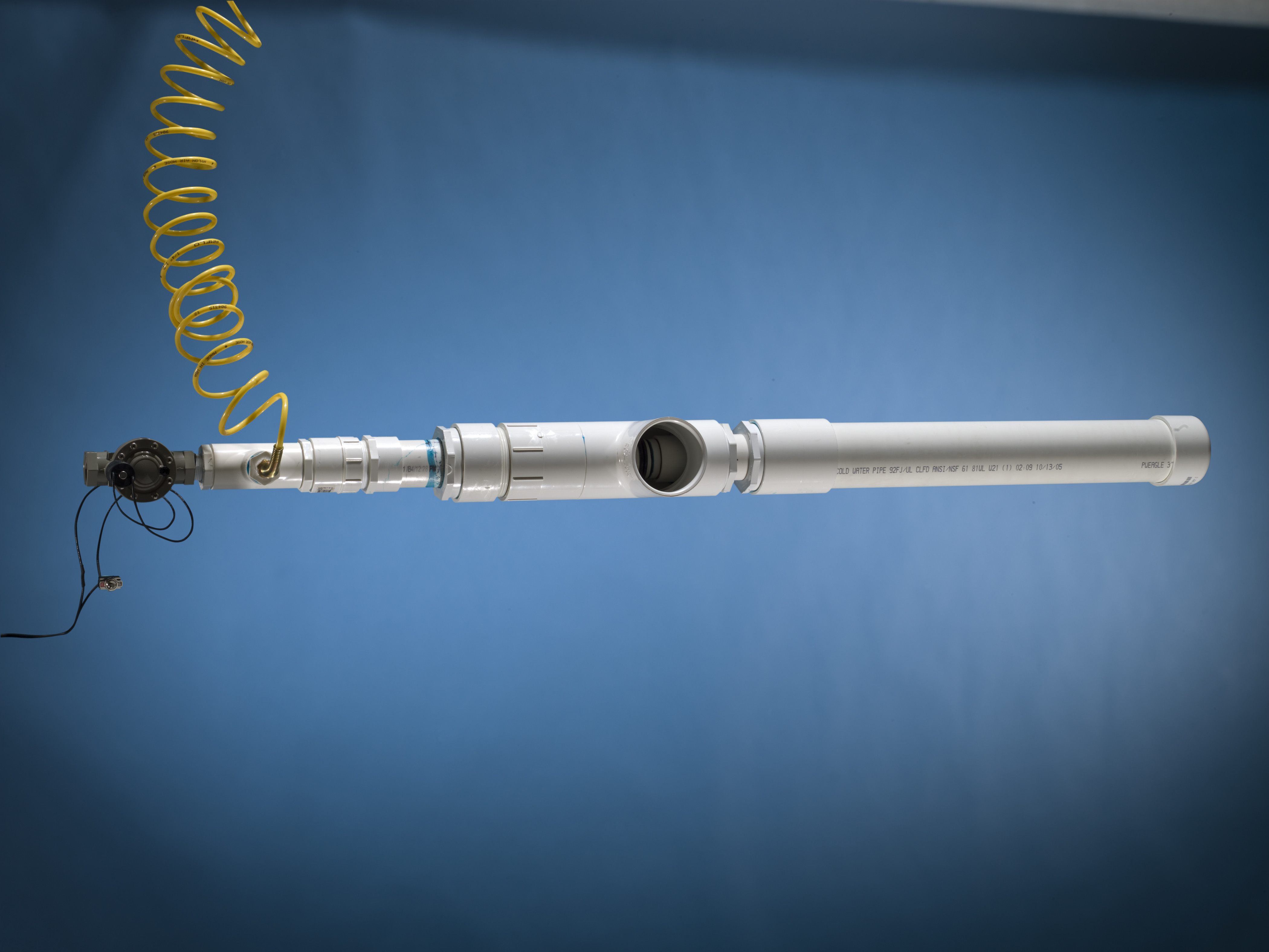

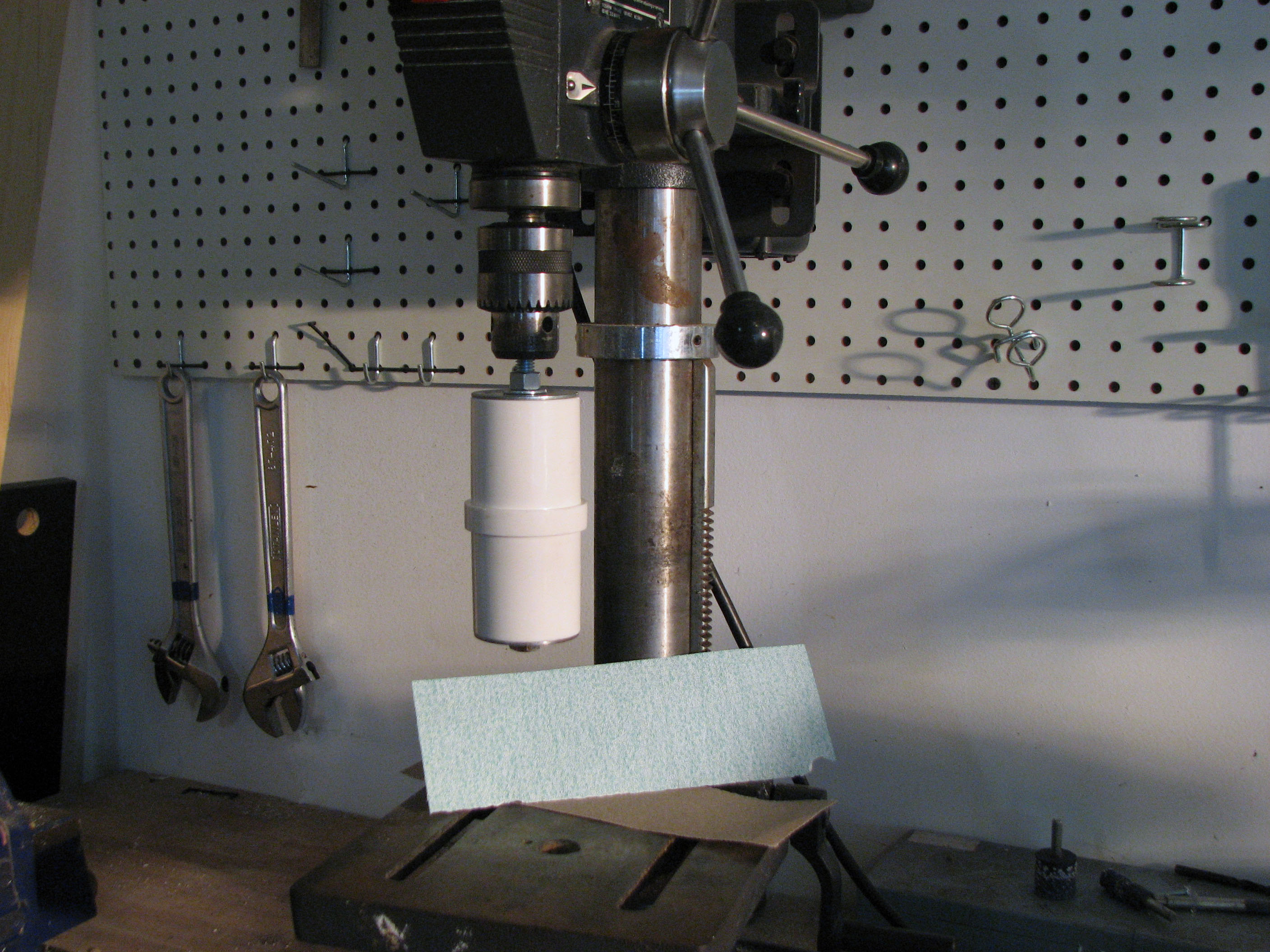

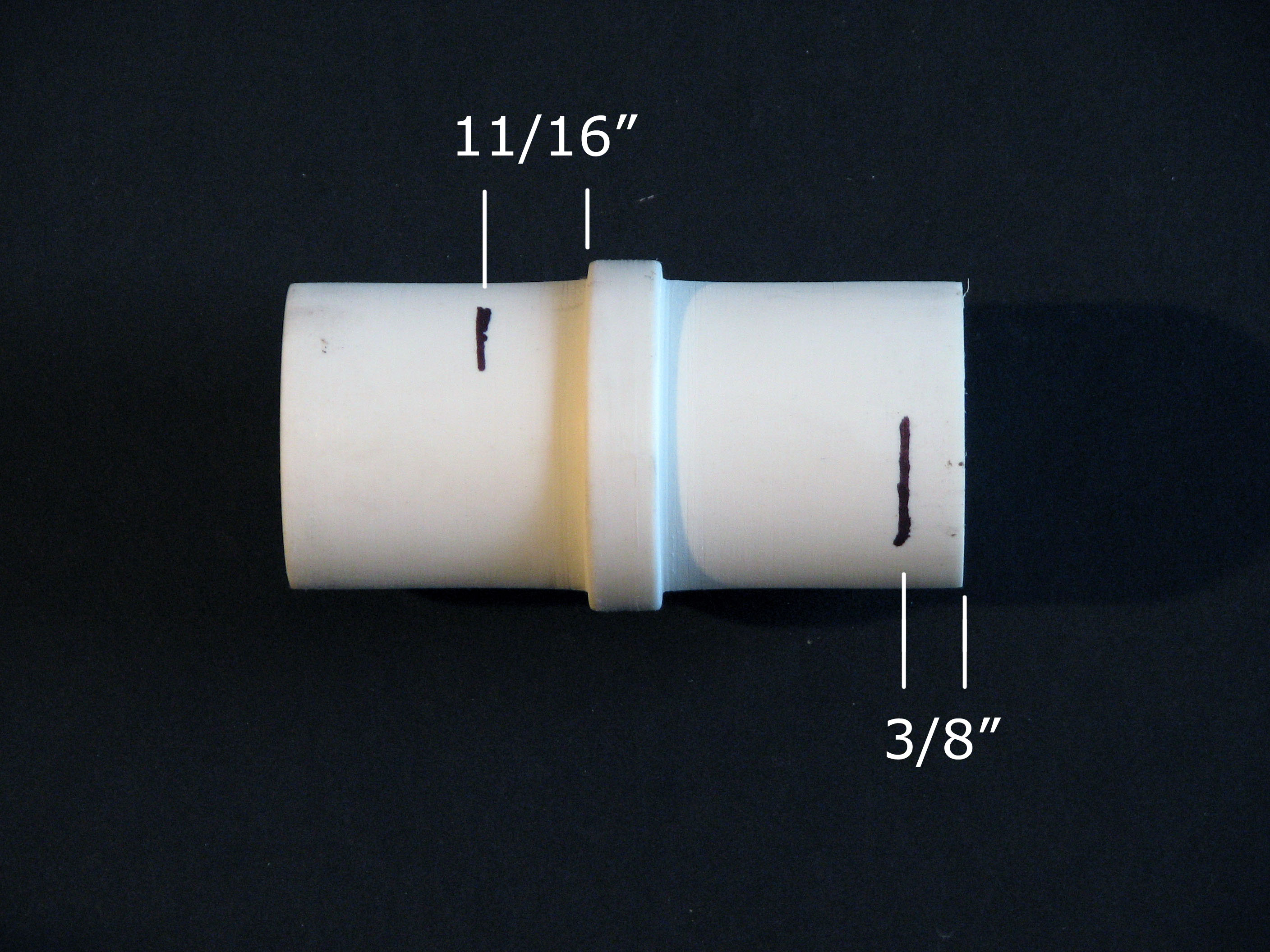

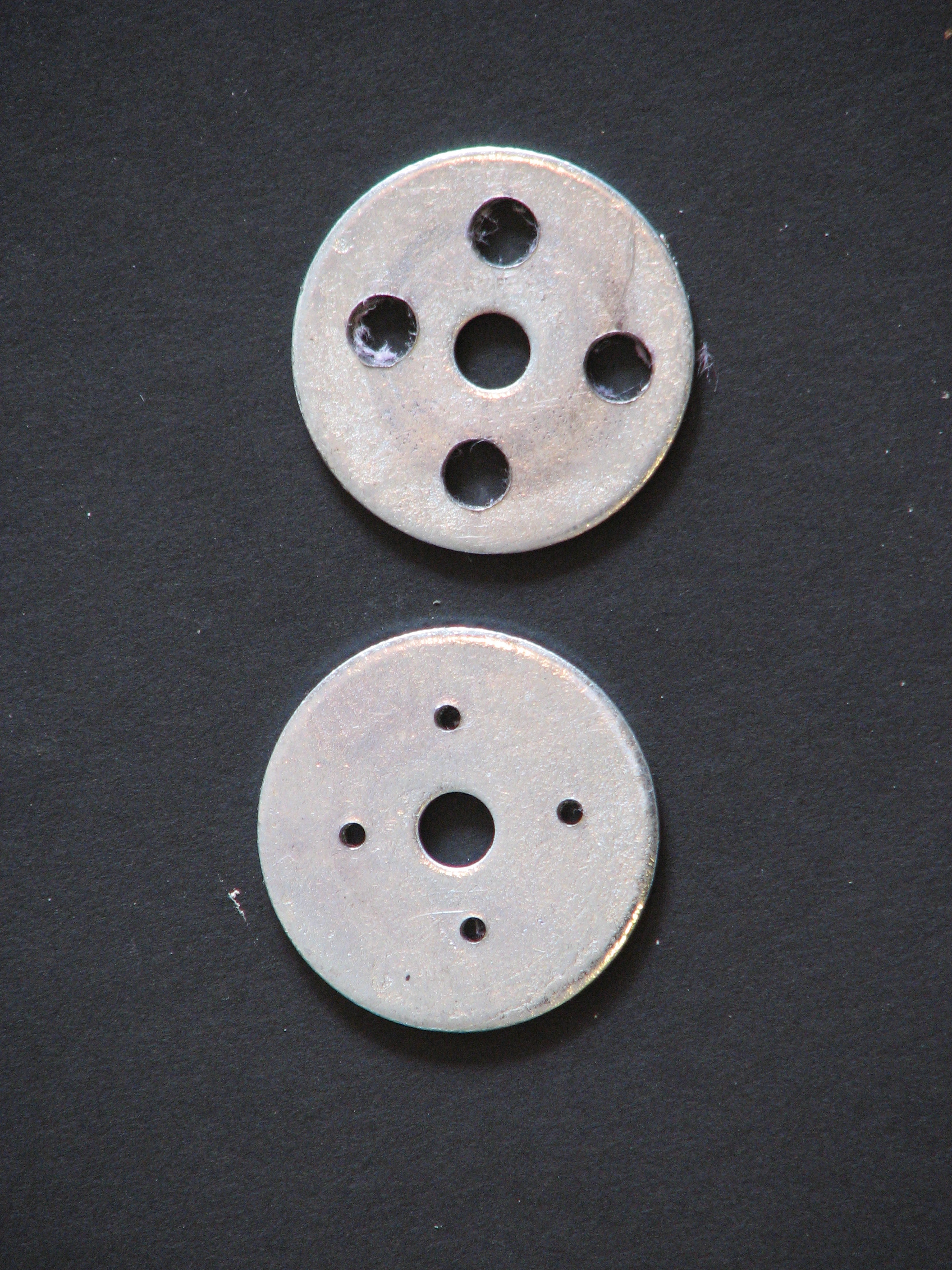

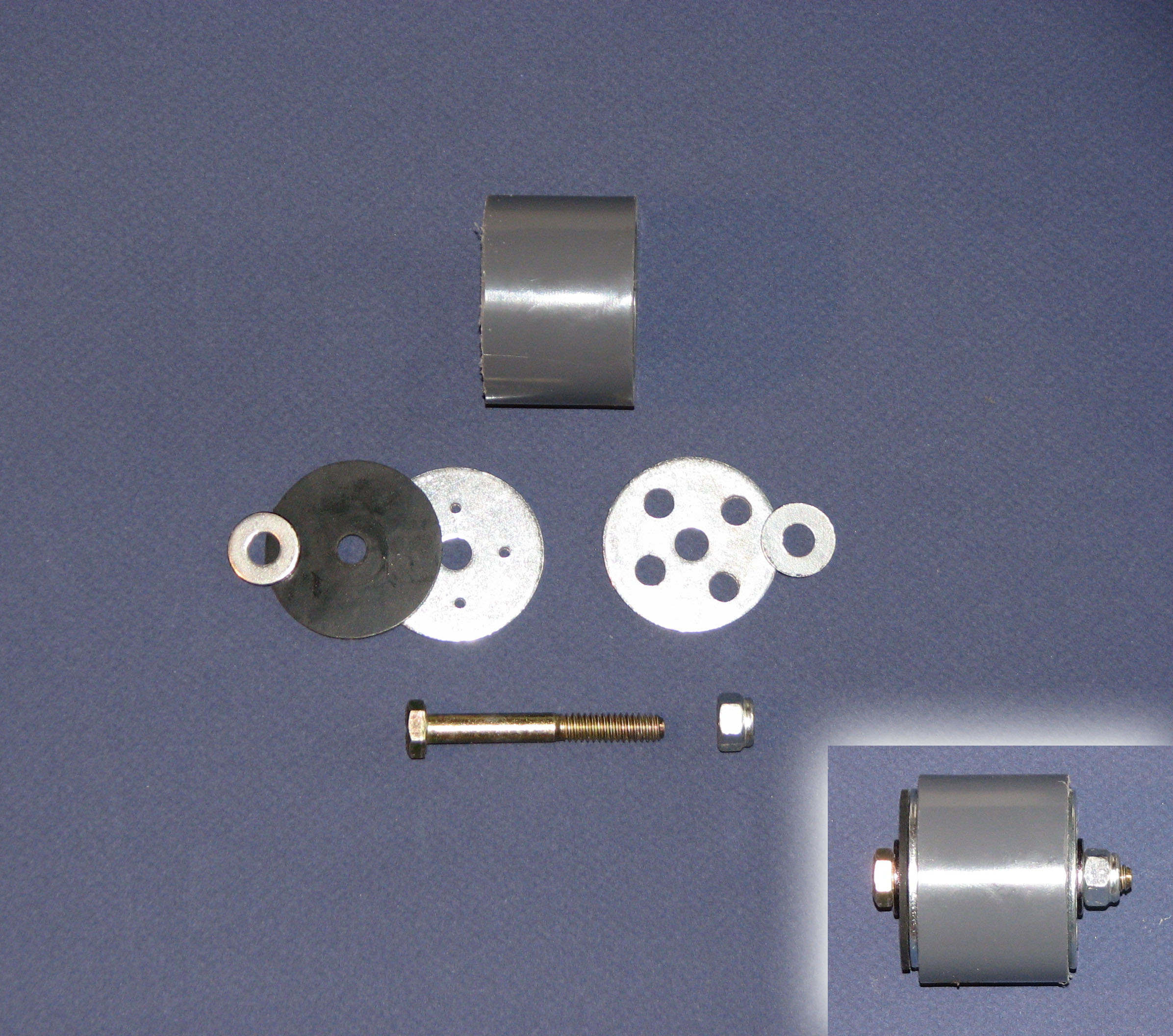

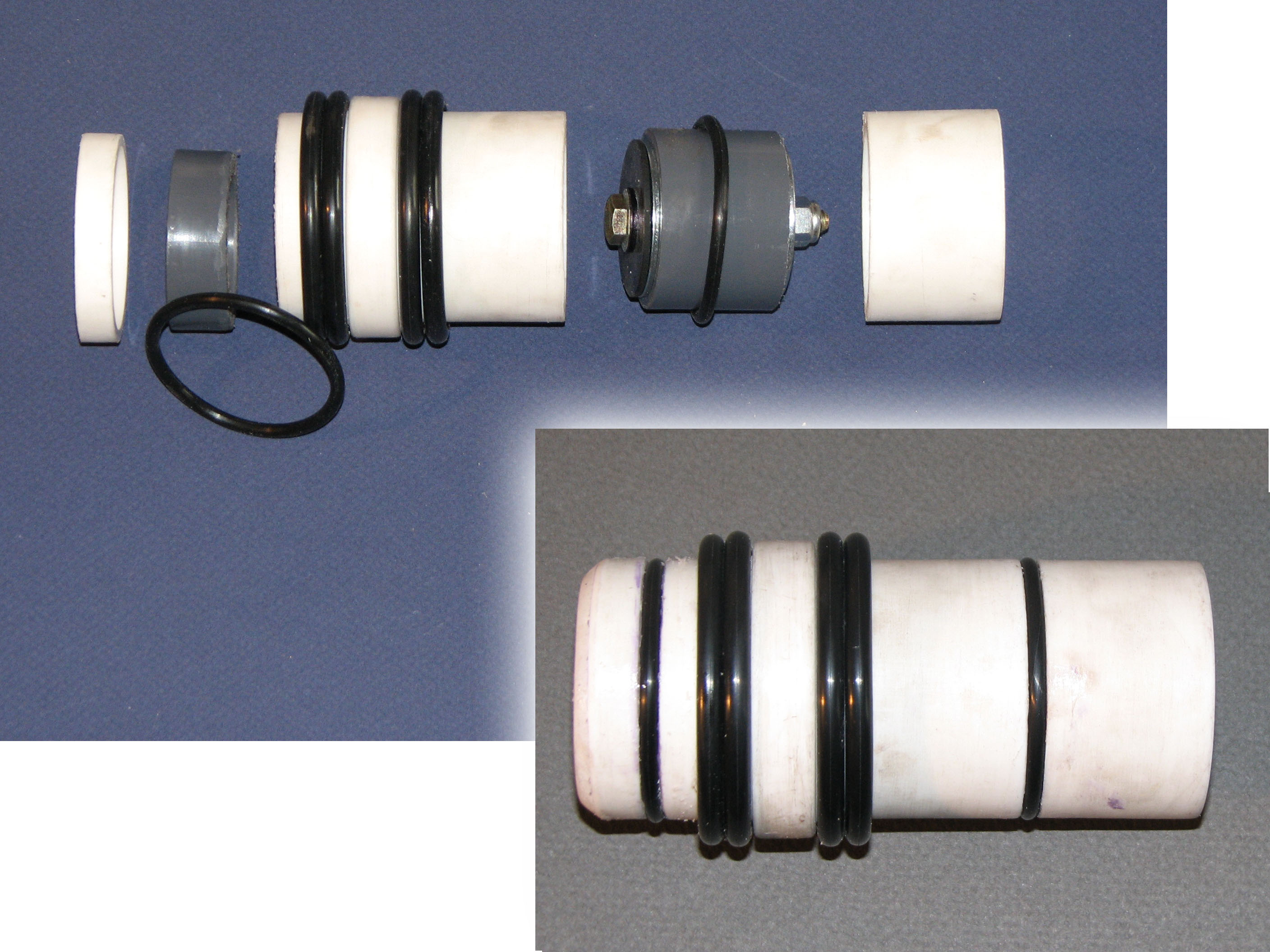

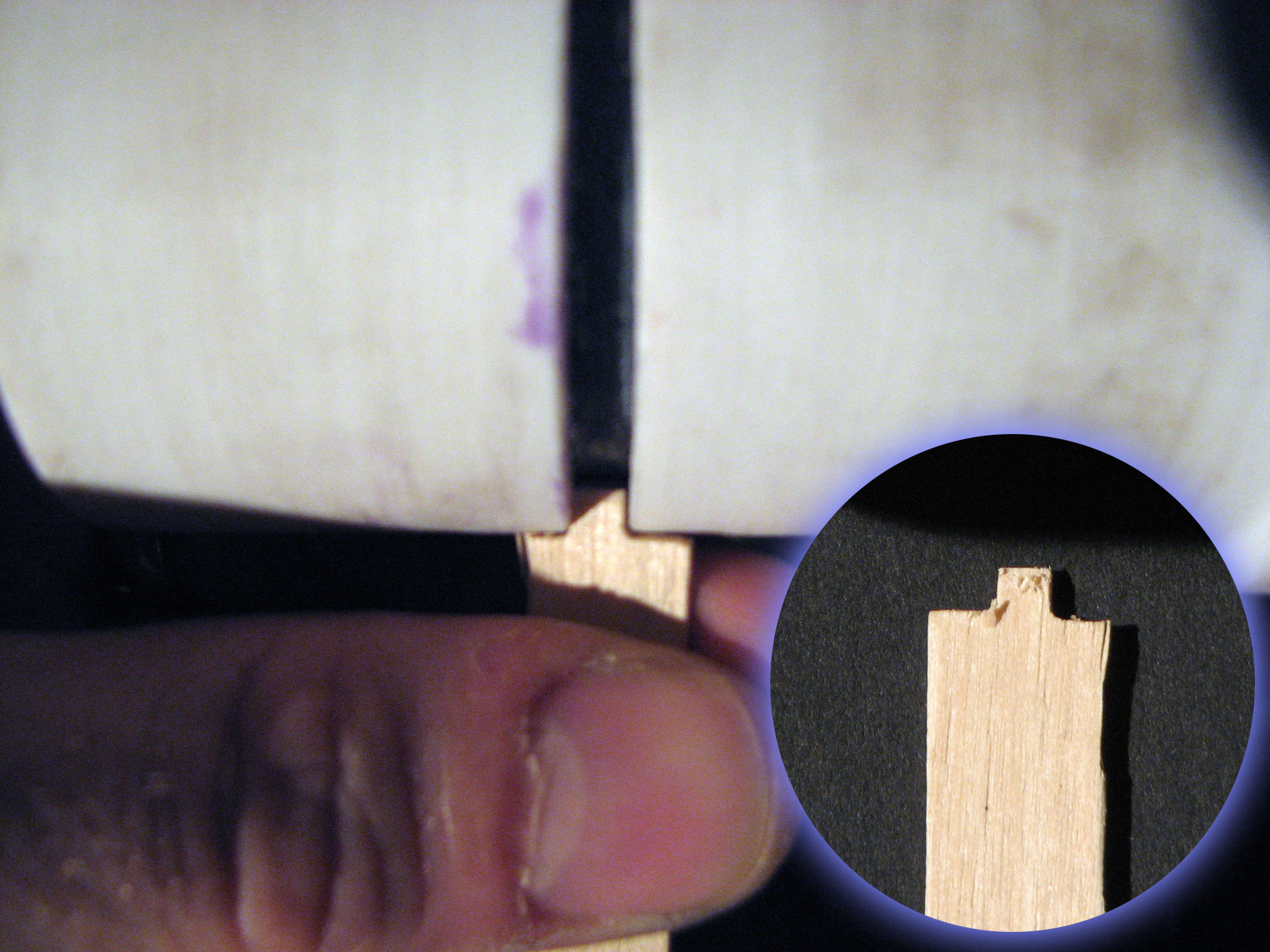

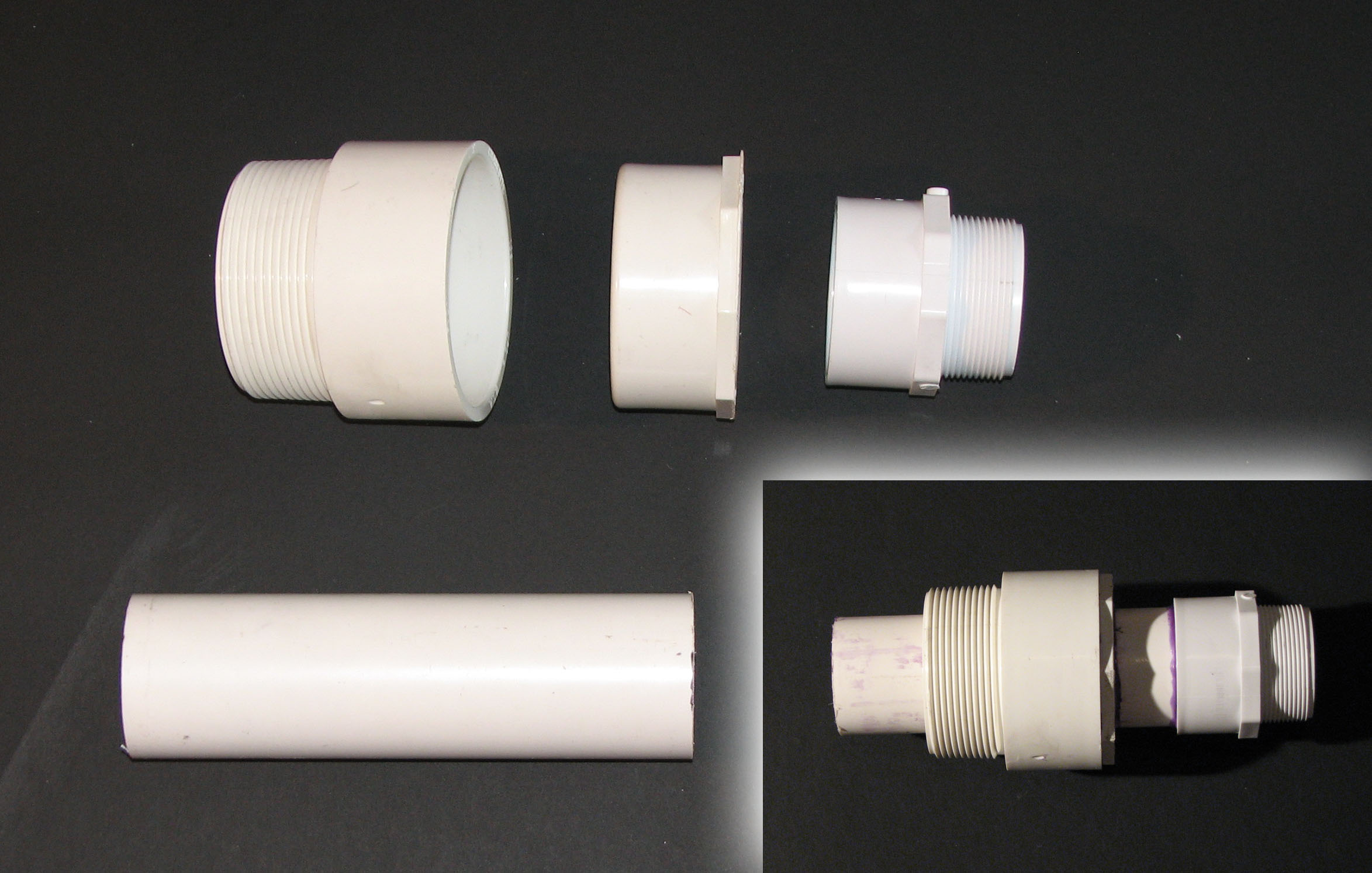

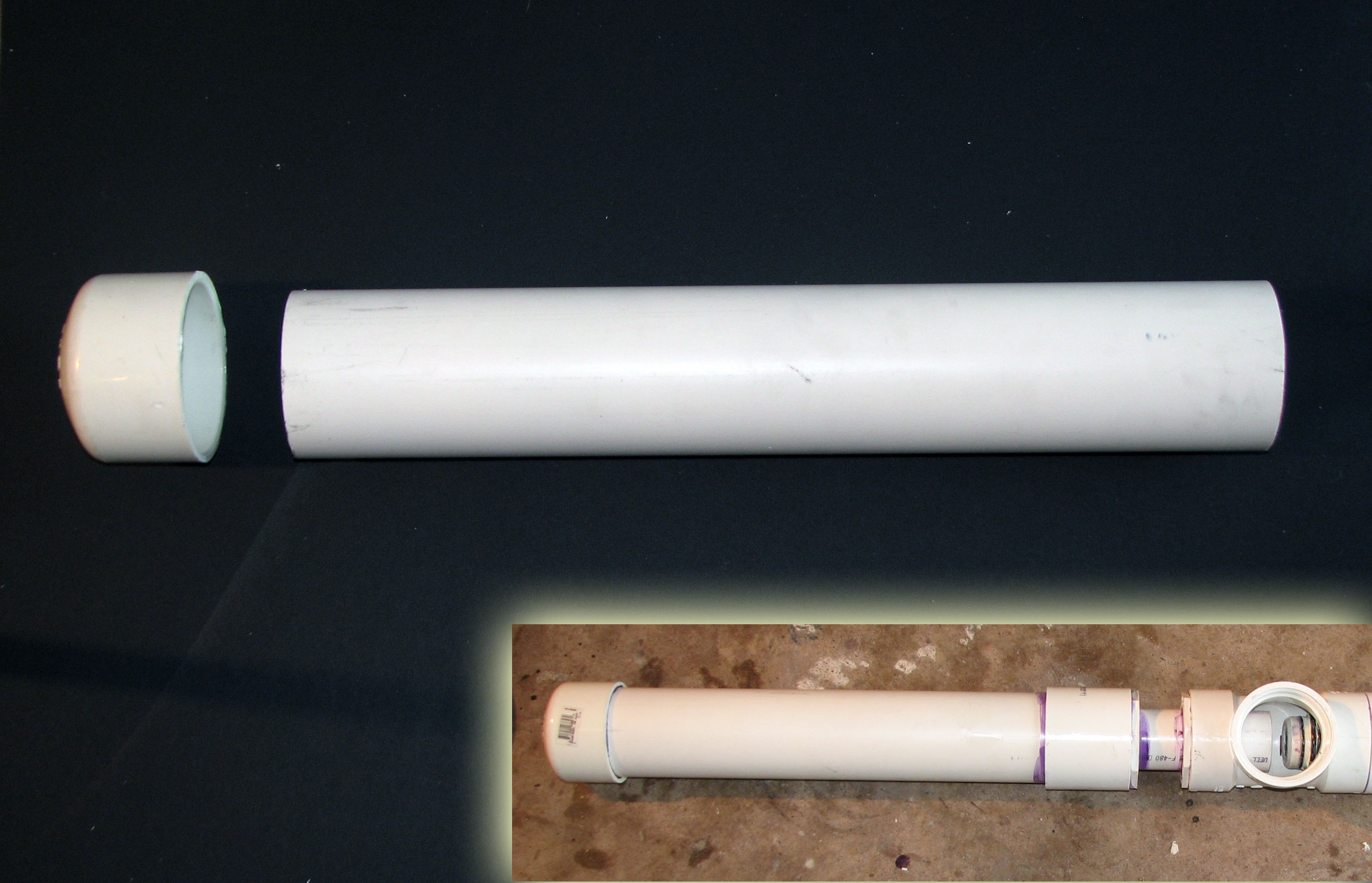

Inspired by the PVC-based designs of spud gun enthusiasts (but leaving out the potato), I’ve found a better approach: a two-stage, chamber-sealing, quick-exhaust, piston-valve air cannon that you can build out of common plumbing components for about $100. I call it the Boom Stick.

Building Boom

The Boom Stick creates a pressurized volume of air and releases it very quickly, generating a loud shockwave.

How It Works

Caution: Dangerous Project

At normal temperatures, standard Schedule 40 PVC has a working pressure of around 150psi, but heat, sunlight, solvents, scratches, and time make the material lose strength, and even at the 40–60psi used for this project, it will eventually fail. When it does, it will break into fragments that will be thrown with great force by the compressed air. Always operate your Boom Stick inside a solidly built plywood box or wall, so that shrapnel cannot reach anyone’s tender flesh.

ABS plastic does not shrapnel like PVC, but the common type used for DWV (drain/waste/vent) applications is not pressure-rated, so it may or may not hold up. Foamcore PVC or ABS is even more lightweight and must be avoided at all costs.

Pressure-rated ABS such as Duraplus from Ipex is the perfect material for this project, but it costs 10 times as much as Schedule 40 PVC. Copper and other metal pipes are similarly expensive.