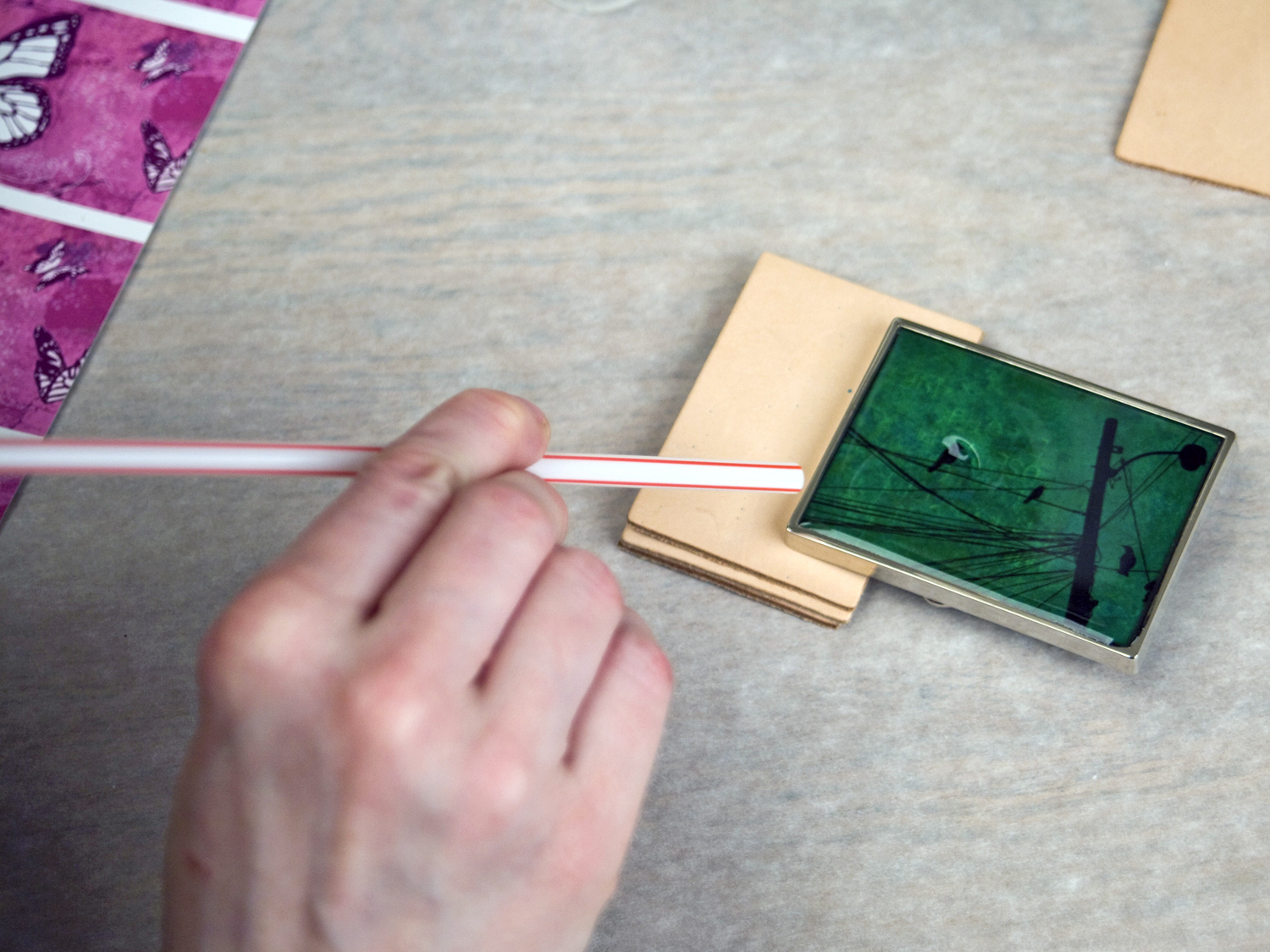

Personally, I prefer art that has a function other than hanging on a wall. I look for various ways to incorporate my photographs and collages into everyday items — items that act as a vehicle to transport images to the outside world. I’ve created mobile exhibits with pendants, rings, purses, business card cases, and my favorite accessory, belt buckles, all with the help of resin, a very simple and versatile medium.

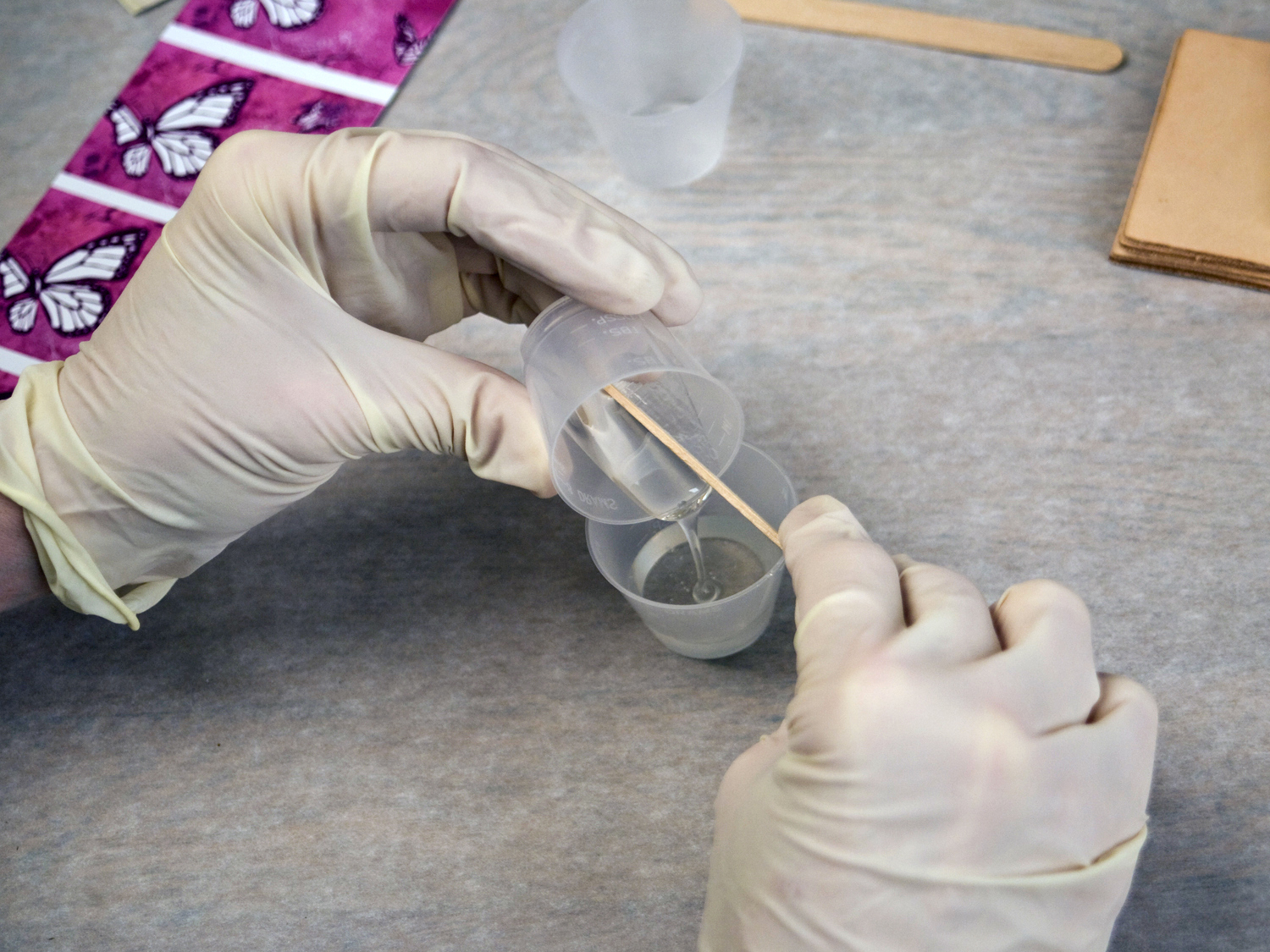

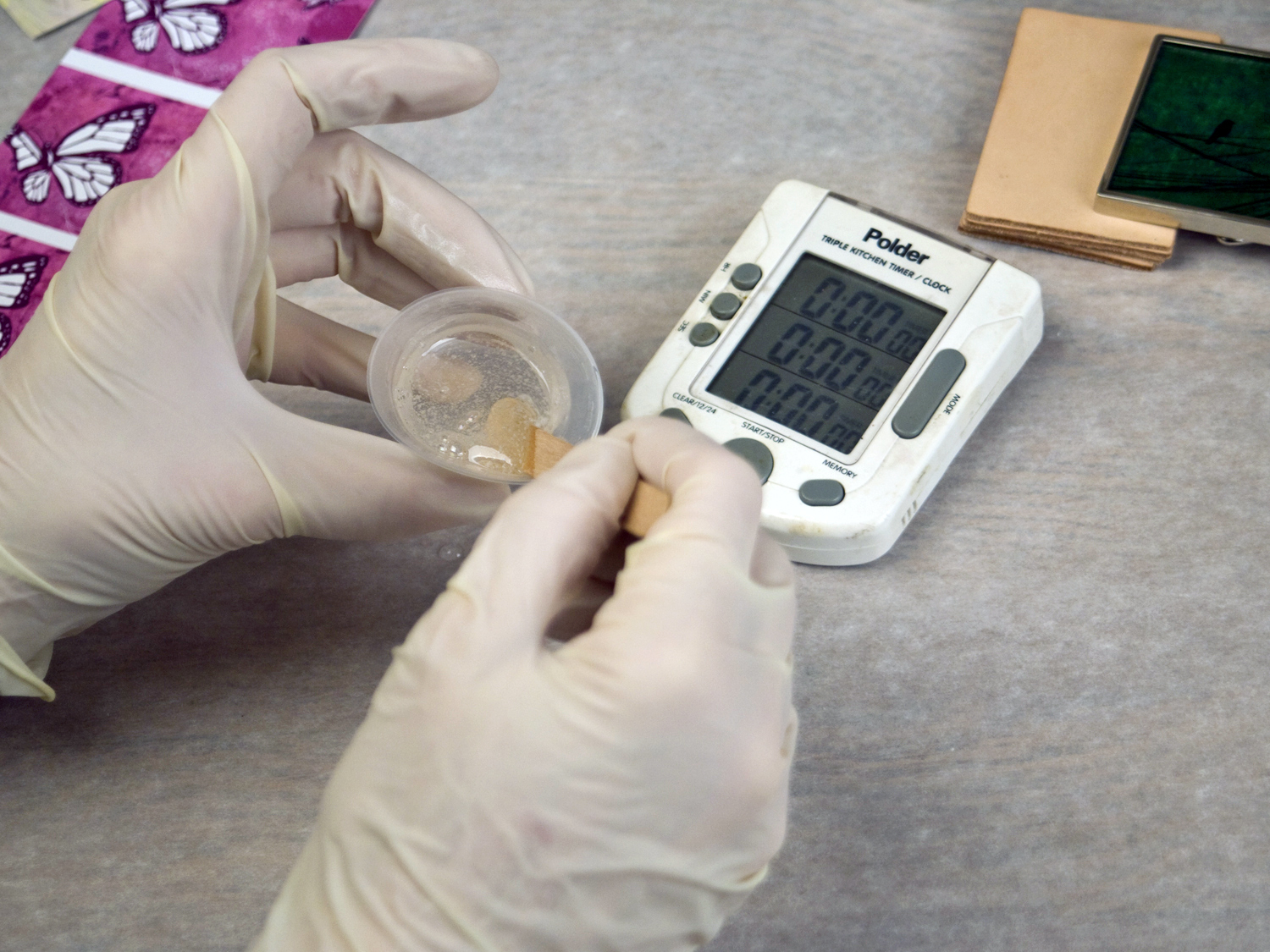

Most resins consist of two parts — the resin and a hardener — that when mixed together cause a chemical reaction that cures the resin to a durable finish. Some types of resin require only a few drops of hardener, while others need equal parts hardener and resin.

Resin is really easy to mix and use, and most projects take only a short time to complete (not including the curing time). Making these resin belt buckles has become an addiction of mine, which I will now share with you.