I love cold brew coffee. Its rich and delicious flavor, and low acidity, means it tastes great over ice. Traditional hot-brewed coffee methods simply can’t compare; when chilled and served on ice they tend to taste diluted and acidic. I have a small commercial drip tower that works very well, however, given the fact that cold brew takes up to 18 hours to brew, it’s disappointing to finish it off in just a few drinks. You can buy large cold-brew towers, but they’re very expensive, aimed at coffee shops. I decided to build a much larger brewing tower from scratch, and to make it considerably higher precision while I was at it — drip rate is everything when it comes to cold brew — using a microcontroller-driven solenoid valve for exact drip rate.

A cold-brew coffee tower consists of three main parts: a water receptacle at the top with a drip control valve, a chamber for grounds in the middle where the brewing takes place, and a carafe to receive the brewed coffee at the bottom.

Sourcing parts was a bit of an adventure. I had planned to use chemistry lab glass for all three systems, but eventually realized that this would be either too expensive, in the case of using a separatory funnel for the tapped water receptacle, or impractical — a Buchner funnel large enough to hold 150 grams of ground coffee would be much too squat and wide to saturate evenly. After much hunting I found the ideal components: a water serving pitcher for the top receptacle, a siphon brewing upper beaker as the grounds chamber, and a flat-bottomed boiling flask as the receiving vessel. For a bit of spiraling glass laboratory aesthetic I added a Graham condenser to the mix, purely for looks.

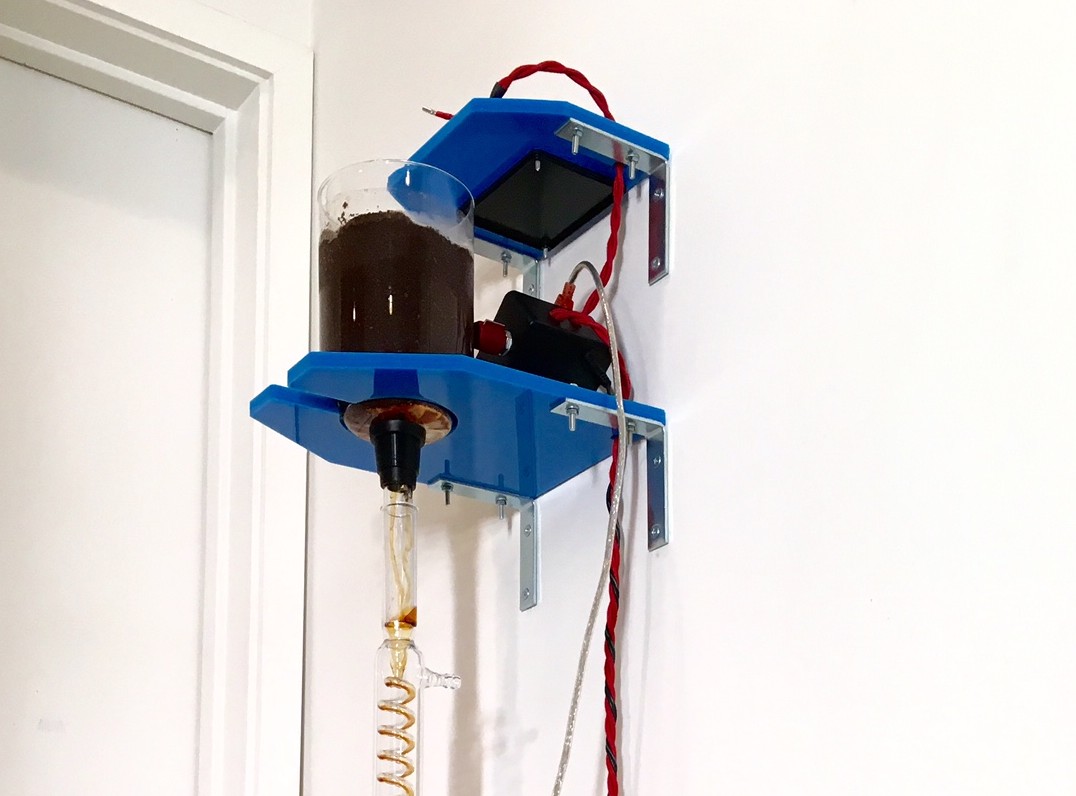

Since this behemoth would stand 4′ tall and need quite a bit of support to hold the components, I decided to mount the tower on the wall using laser cut acrylic holders connected to angle brackets. If you don’t have access to a laser cutter, you can print the linked files and use them as a guide for cutting with a bandsaw or scroll saw.

For ultimate control over the water drip rate, I chose a food-safe solenoid valve and I built an Arduino-based controller for it. The controller consists of a transistor circuit mounted on a prototyping shield, two 1000-ohm potentiometers, and a bit of Arduino code running on an Arduino Uno. This allows you to use the two knobs to adjust the frequency of the valve opening and closing, and the length of time it remains open per drip. Since the volume of water the solenoid valve allows through is much more than we want per drip for a long, overnight brew, I needed to reduce the size of the drip tube inner diameter. I attempted this with various tubes, straws, and fairly janky contraptions, until I eventually succeeded when I “borrowed” the miniature drip valve from my small commercial brewer. A Hario valve (available from coffee parts suppliers online) press-fits very nicely inside ¼” tubing — you can use any food-safe stopcock valve that fits.

Some of the fittings will be specific to the dispenser and solenoid valve you choose, so it’s best to bring these parts to a plumbing store for help with parts.

![Make_coldBrewRack [Converted]](https://i0.wp.com/makezine.com/wp-content/uploads/2016/05/Make_coldBrewRack-Converted-620x512.png?resize=620%2C512&ssl=1)