The smartphone is our favorite tool, but also a huge time waster. If you need a little help with self-control, grab a 3D printer, some electronics, and these instructions. This tiny time-controlled safe makes your smartphone disappear for a while and frees up time for other things.

First, something important up front: we’re printing our safe in plastic, so it’s not theft-proof and does not offer a 100% guarantee against misuse. If you lock up your children’s cellphones, you have to expect that their intrinsic motivation will be so high that they’ll find ways and means to break in, either by programming it or by using brute force. The point of this project is to show you how to build a device like this, what you need to think about, and to give you tips and tricks for further expansion.

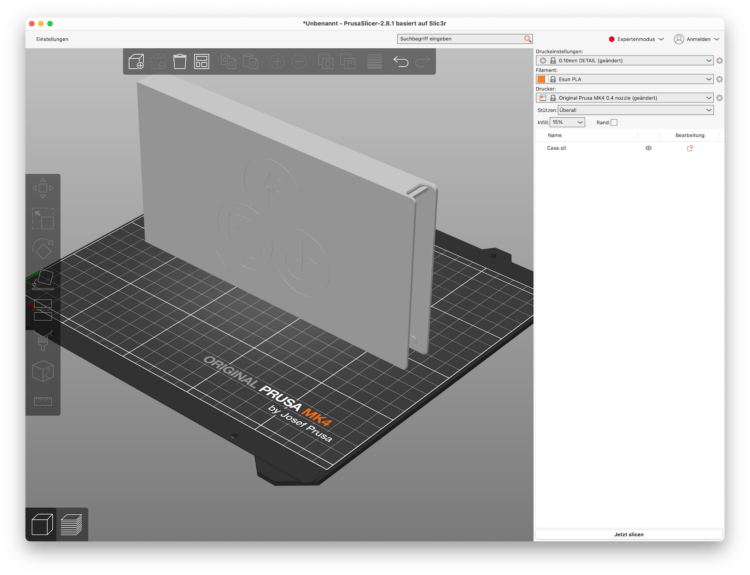

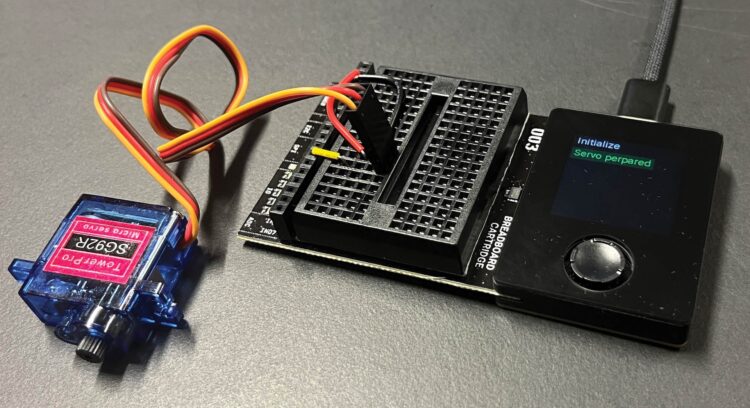

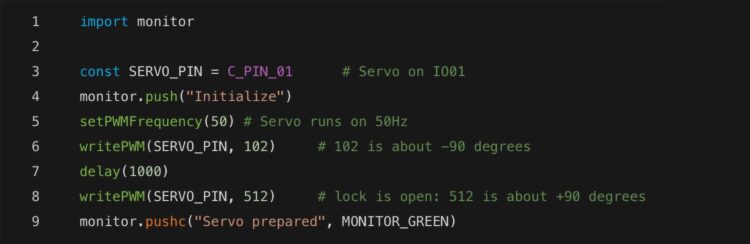

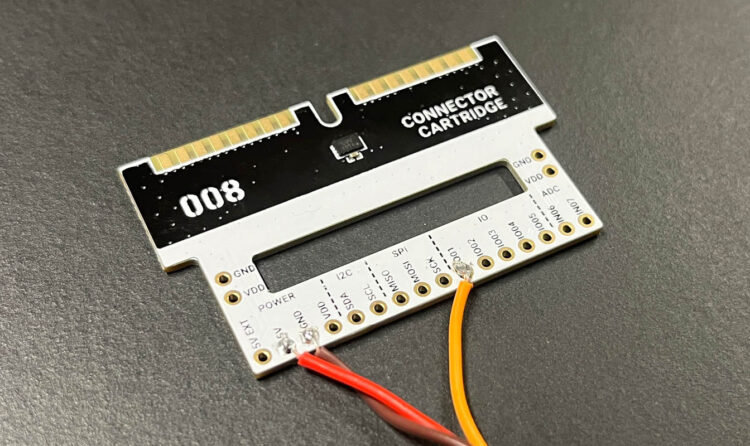

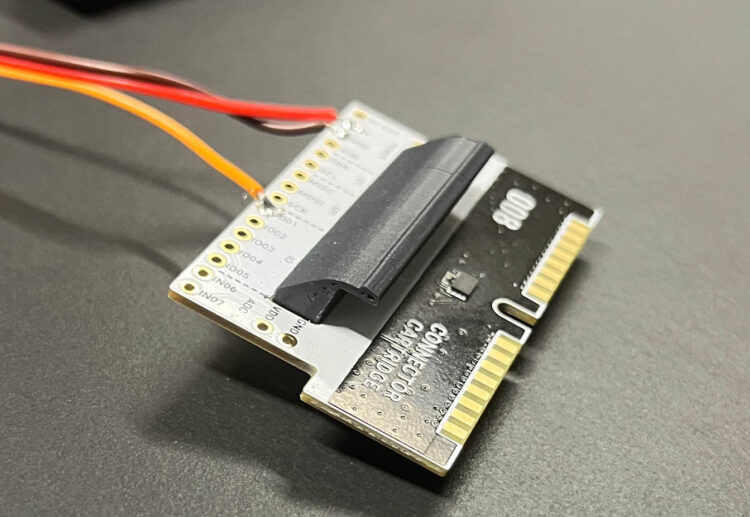

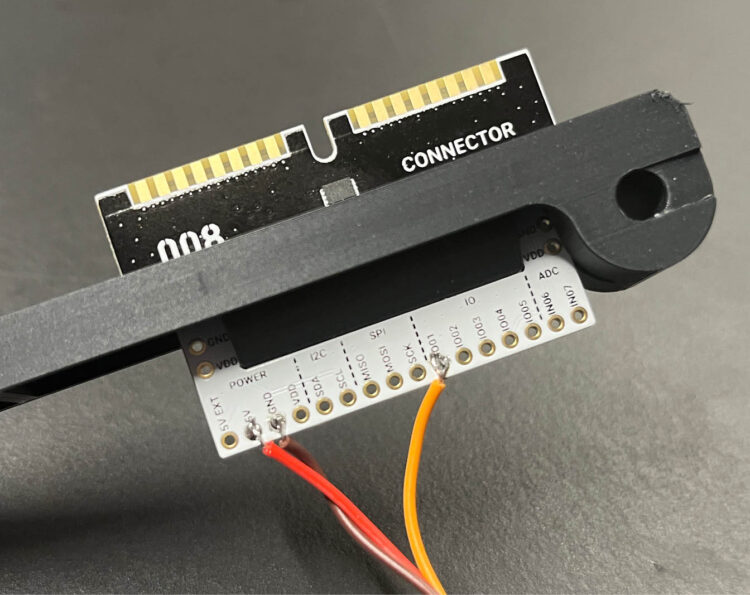

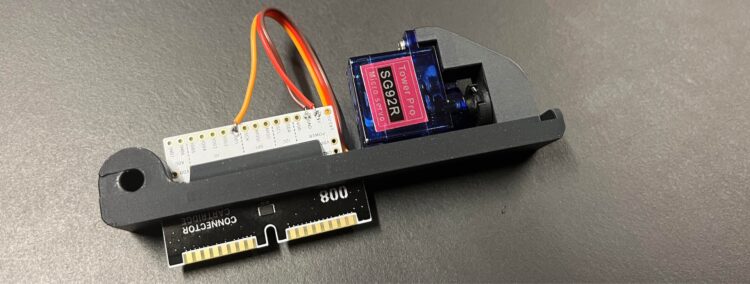

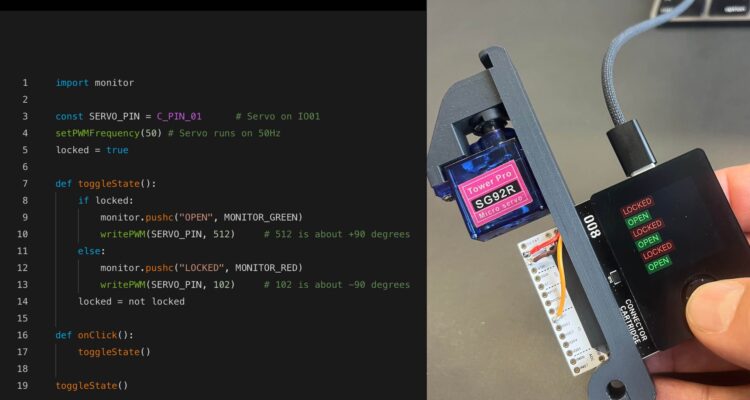

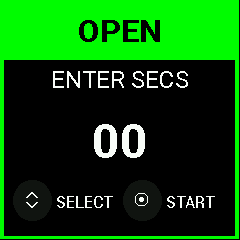

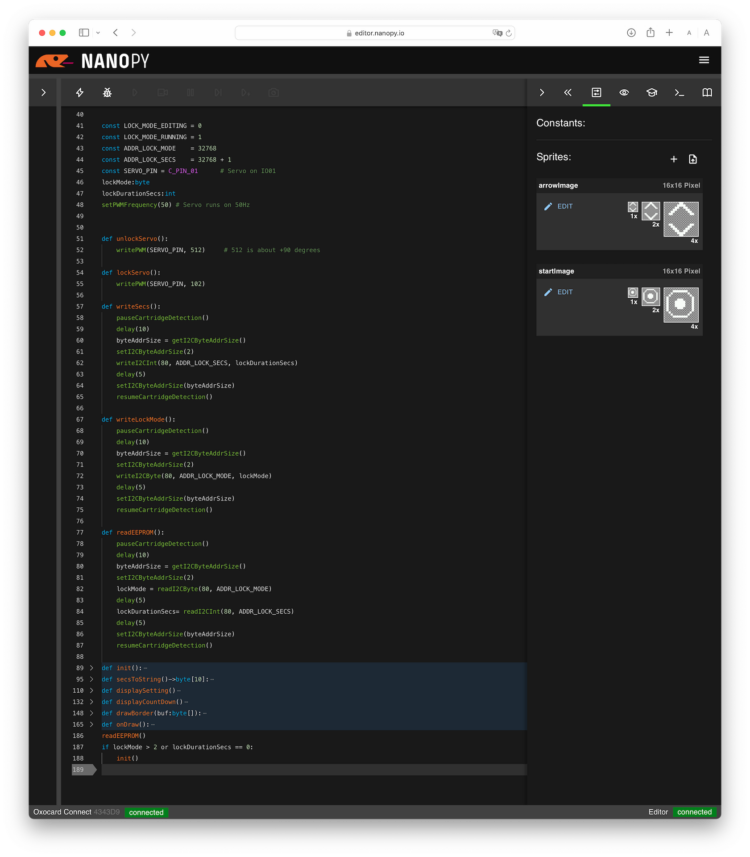

Our cellphone safe — you could also call it a prison — consists of a container and a lid. The lid contains a locking mechanism that is controlled by a servo. The device is plugged into an external microcontroller via a connector cartridge. We use the Oxocard Connect here to make things easy. This runs a small app that allows you to set how long the safe should lock the phone away. As soon as the time has elapsed, the safe opens and you can check your emails again or swipe and scroll through the endless expanses of social media to find the latest “news.”

Mechanical structure

The appliance essentially consists of two parts, the container and the lid with the locking mechanism. The lid is simply inserted by opening it fully (90°) and placing it over the two short axle cylinders. A crossbar fits on the other side so that the lid can be locked in place. When the servo extends the bolt, the housing is closed.

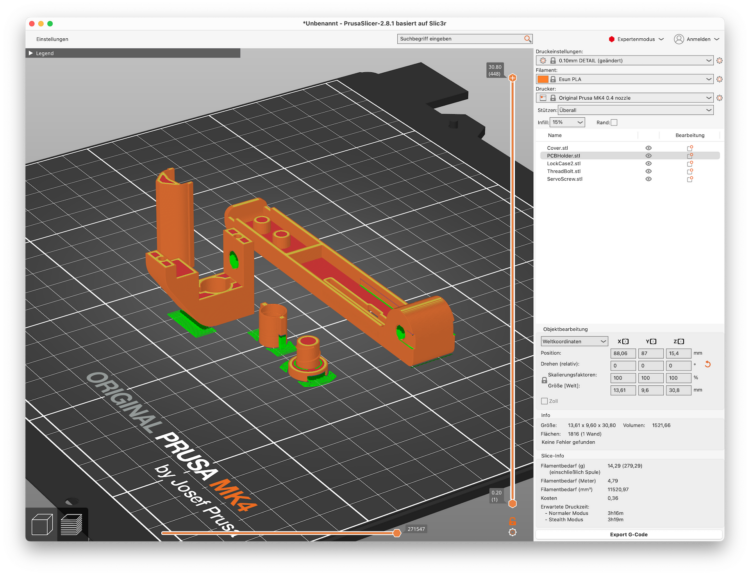

Closing mechanism

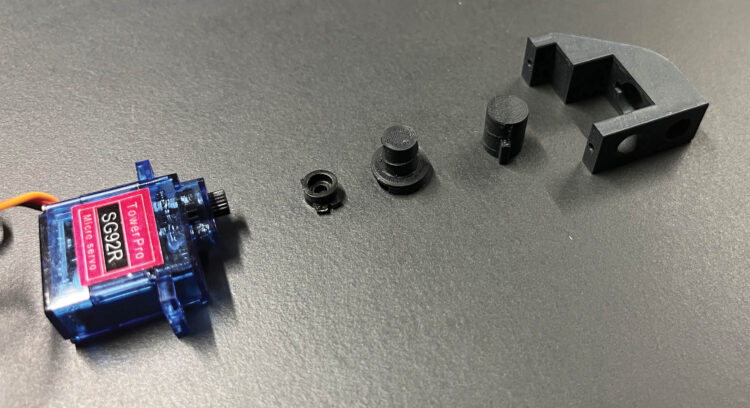

The core of this safe is the locking mechanism. For this we use a commercially available micro servo (SG92R) as found in the Make: Oxocard Connect Innovator Kit.

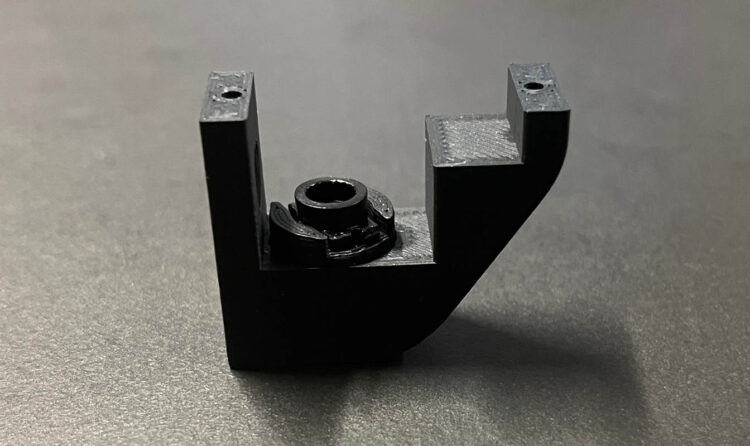

The servo is mounted in the lid and controls a closing mechanism that converts the servo rotation into a linear lifting movement to move a bolt. For this we need a servo with a truncated servo horn. Onto this, we place two plastic parts that screw into each other, to create the screwing movement. The outer part is prevented from rotating by two small rails, so the bolt moves outward and the rotary movement is converted into a lifting movement.

The whole thing is reminiscent of a screw with a nut. If we turn the screw while holding the nut with our fingers, we turn the screw in or out. But because the servo rotation is a maximum of 180°, we need a much higher thread pitch than a screw. In our case, the thread pitch is approximately 4mm–5mm. At 180° rotation, the stroke distance is approximately 2mm–2.5mm.