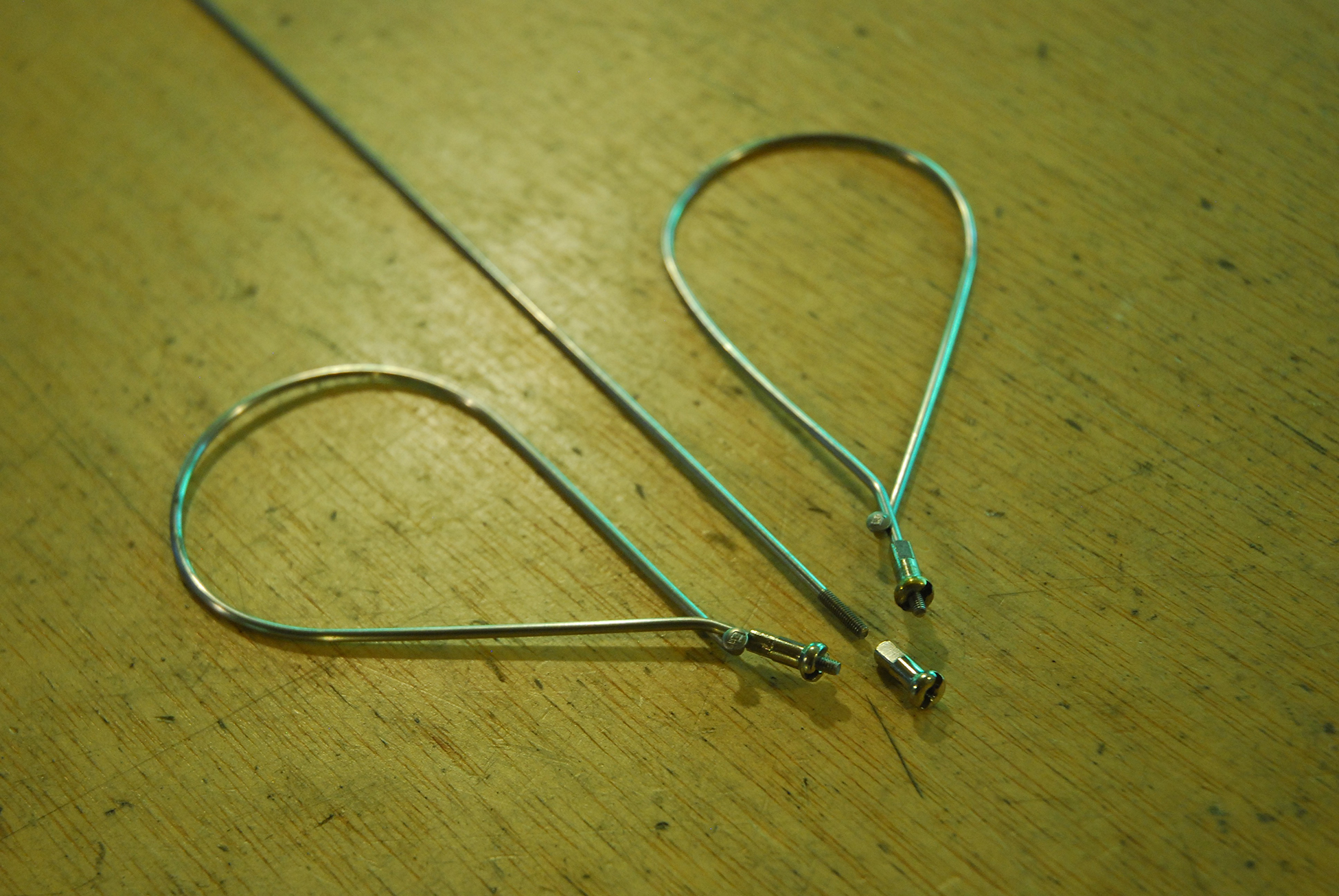

As a custom bike manufacturer, I make all my own tooling. Most of it is advanced or heavy duty, but I’ve also made some simple, elegant tools from old spokes.

This tutorial is for a nipple driver, which winds the nipples — the little pieces that hold the spokes to the rims — into the rim. It’s made easily on a bike stand with a pair of pliers.

When lacing a wheel (or spoking a wheel, the first step of a wheel build), the most time consuming part is individually threading the nipples to the bike spoke heads. Nipple drivers aid in this step. The first couple spokes are easy because you have a lot of slack, because the spokes can be pushed very far through the rims’ spoke holes. But as more spokes are added and the hub is centered, this task becomes trickier, and you definitely need something to hold the spoke, push it through the hole in the rim, and twist it on to the spoke head to a uniform distance for each spoke. A nipple driver, like this one, helps with that task.