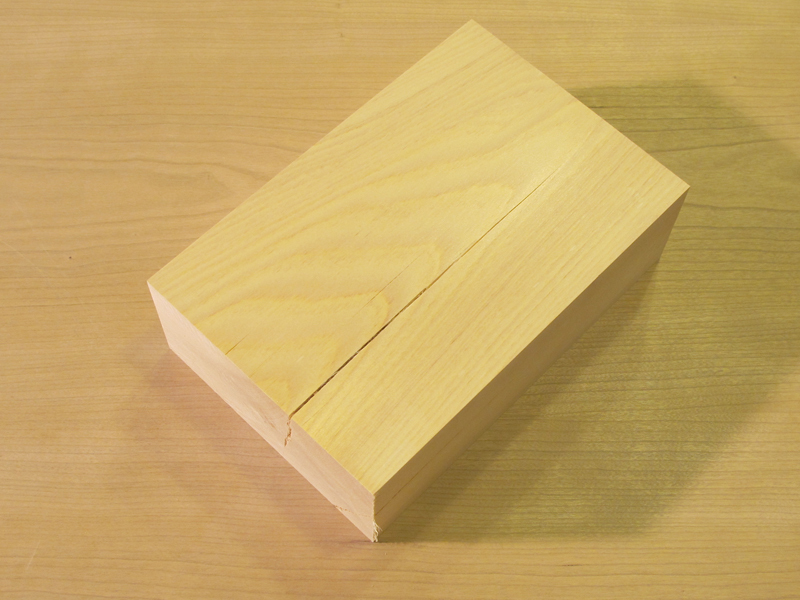

When working with wider, thicker slabs of wood, it is not uncommon to have checking (cracks) in the surface, particularly at the ends. While there are a couple of ways of dealing with this, such as filling the gaps with wood or putties or epoxy, I prefer to leave it as it is, treating it as a feature instead of a flaw and stabilizing the check with a butterfly spline.

Projects from Make: Magazine

Butterfly Spline

"Arikata" is a method of stabilizing checks in thick slabs of wood in aesthetically pleasing way. It can be used for joining boards together for tabletops etc.