Has your cat left scratch marks on everything from grandmother’s kneecaps to your grandfather clock? It’s time to train Kitty to use this scratching post instead of everything else in your home.

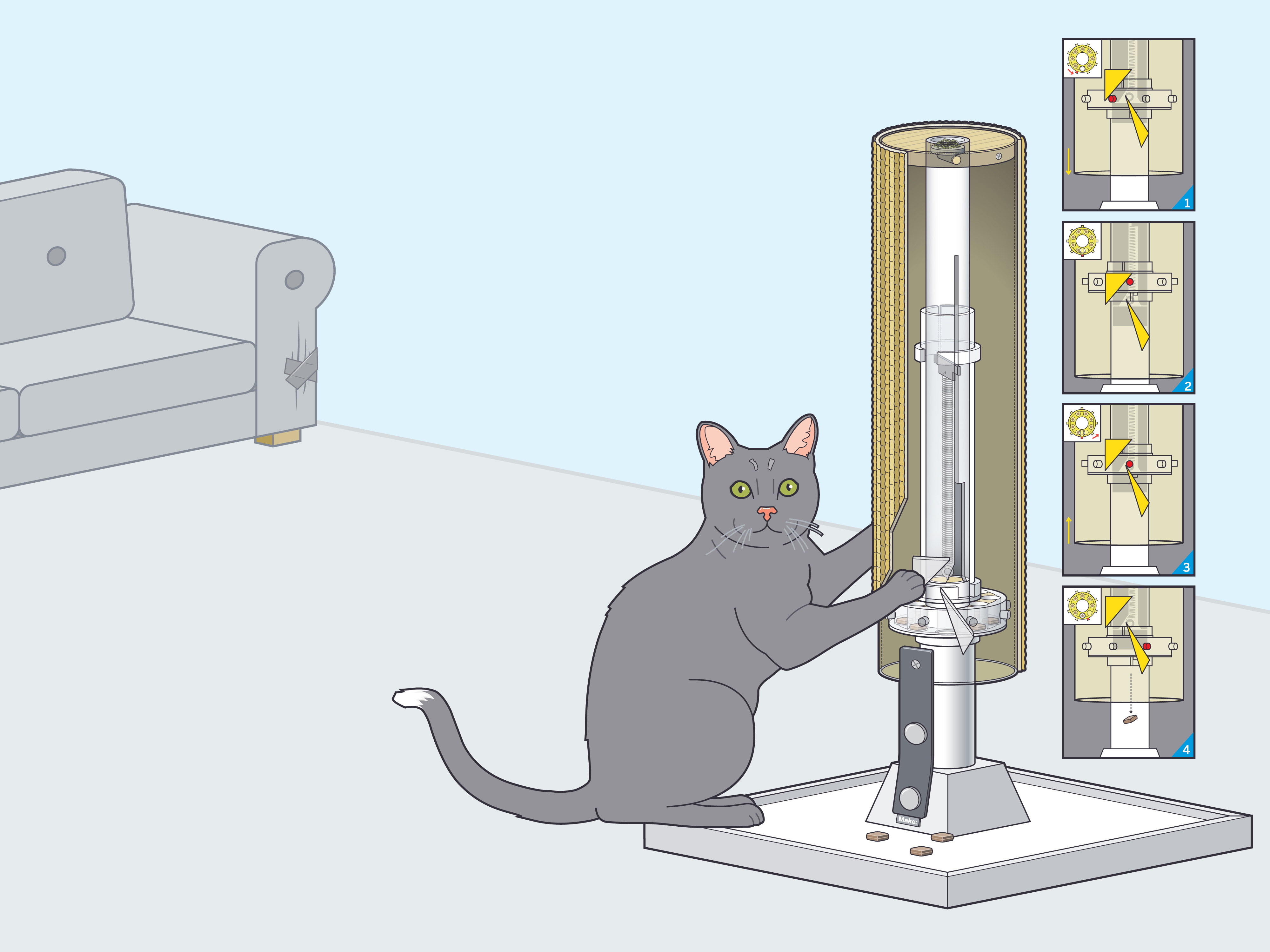

A catnip cup in the top will attract your cat and place her in natural scratching position. Each time the cat claws downward on the spring-loaded carpeted cylinder, this device will deliver up to 4 special treats. Because you control the number of treats, you can keep your cat lean and gradually wean her off the treats altogether as she becomes accustomed to using the post, if you wish.

Download the full-size turntable template and cylinder inner wedges template.

MAKE Volume 33 features our special Software for Makers section covering apps for circuit board design, 3D design and printing, microcontrollers, and programming for kids. Also, meet our new Arduino-powered Rovera robot and get started with Raspberry Pi. As usual, you’ll also find fascinating makers inside, like the maniacs on our cover, the hackers behind the popular Power Racing Series events at Maker Faire.

Try your hand at 22 great DIY projects, like the Optical Tremolo guitar effects box, "Panjolele" cake-pan ukelele, Wii Nunchuk Mouse, CNC joinery tricks, treat-dispensing cat scratching post, laser-cut flexing wooden books, sake brewing, growing incredibly hot “ghost chili” peppers, and much more.

On newsstands now, by subscription, or available in the Maker Shed