Additional Materials Required:

- Steel Nuts (2)

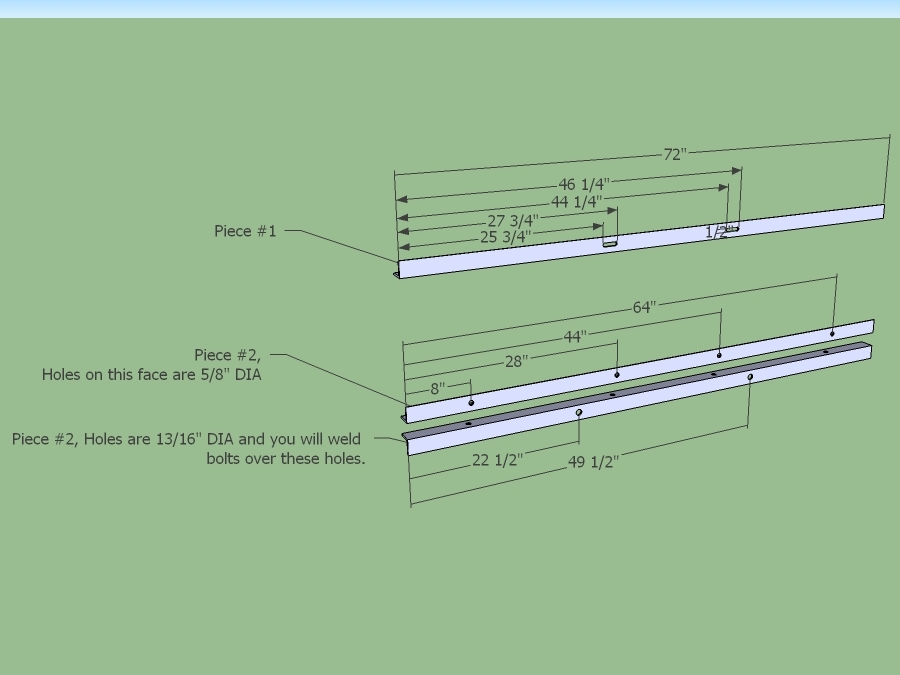

Torch all holes in the 72″ 2×2’s as shown. Note that the slots are 1/2″ tall. (hard to see in diagram)

Make sure you can fit the proper size bolt through each hole.

Grind away any slag

Weld the nuts to the proper 2×2.

Protect the threads while you weld.

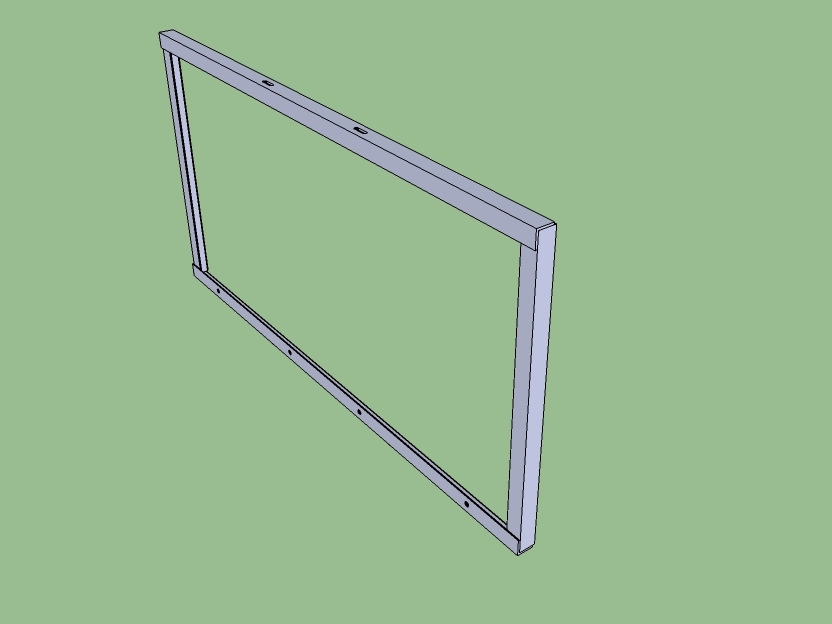

Weld the angle together to make the frame. The short pieces are sandwiched between the long pieces. See the diagram.

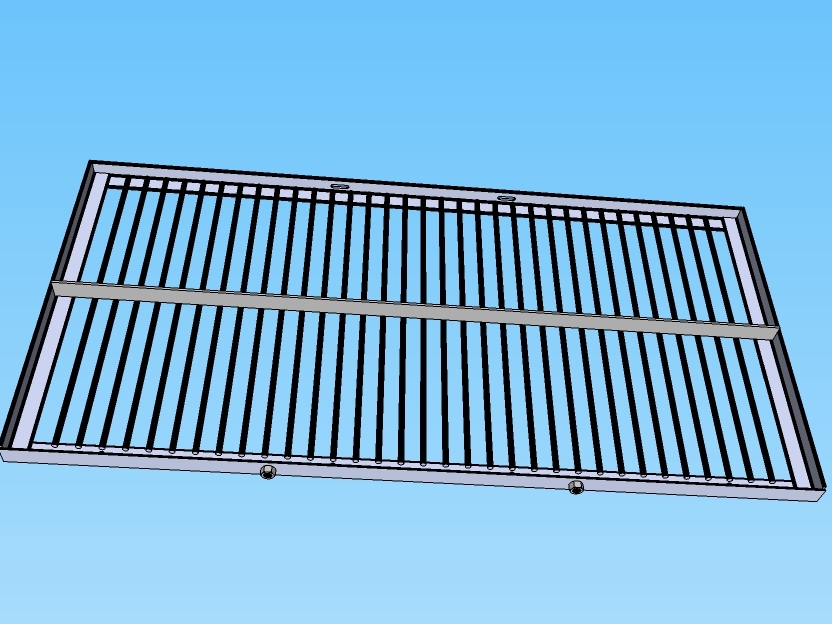

Weld all of the rebar inside of the frame.

It would help to find some 1.5″ spacers laying around the shop so you can place them between the rebars quickly and be sure they are square. Nuts and hydraulic fittings might be the right size.

Weld the cross support (the 1/4 x 2 flatbar) in centered and perpendicular to the plane of the frame.