You have just finished building an awesome electronics project. Now you need to find a housing for it. You could just stick it in a plain plastic box. But project enclosures that you buy from a store are expensive and are rarely the right size.

So why not build your own custom project enclosure? You can save money. You can make it exactly the right dimensions. And it is one more thing to be proud of.

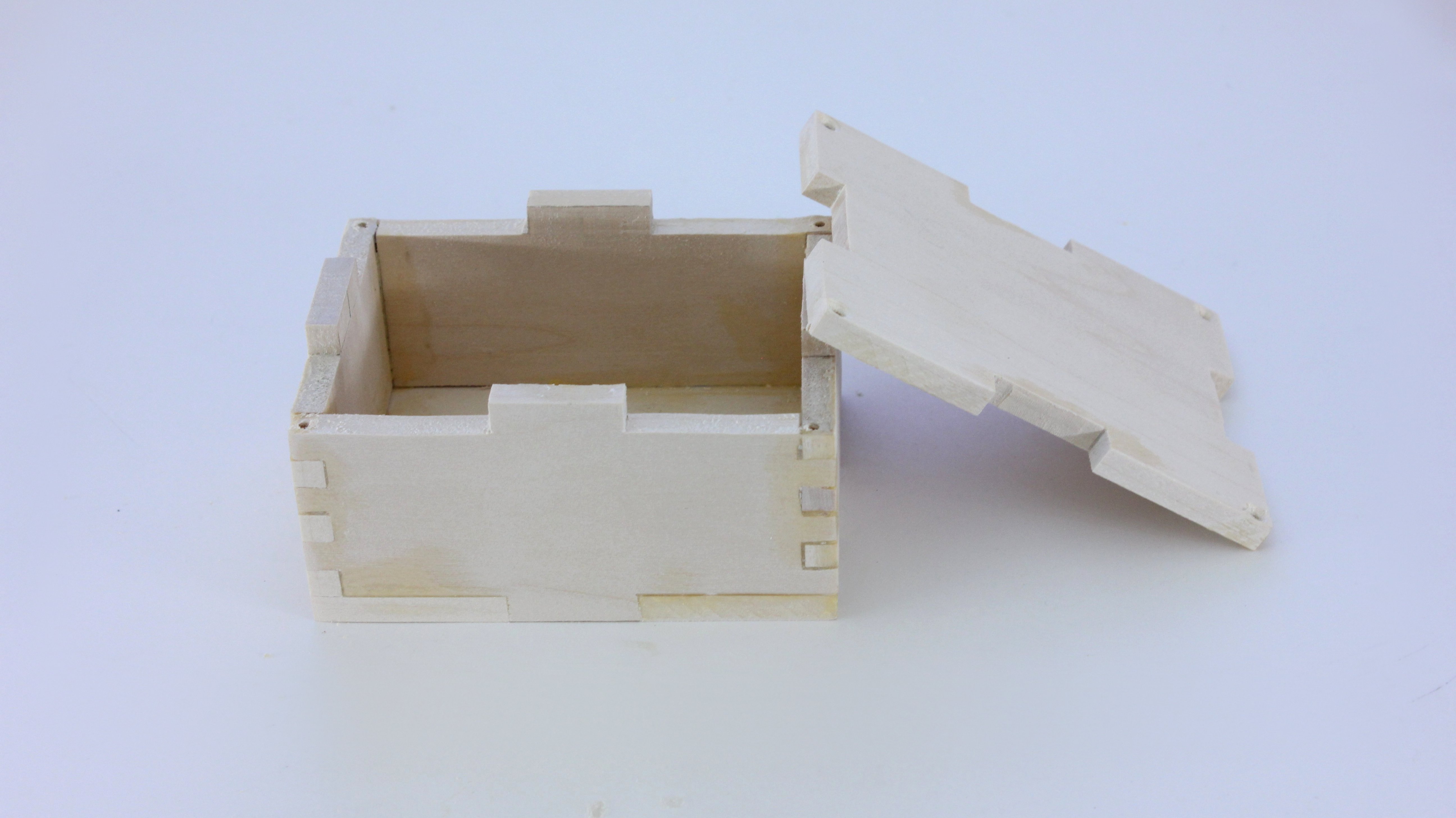

In this project, I am going to show you a simple way to make custom project enclosures from wood.