This project is part 1 in the building a robot arm tutorial. In the second part I show how to design the base and in the third part I show how to design the mount section. Part four will show how to add control with an Arduino.

The best part about robots is that they can take any form you want them too. From little Roombas to large scale industrial manufacturing robot arms, there is almost no limit to what form a robot can take.

Still, some robots seem a little more out of reach than others. Those large-scale robots that build your cars are both extremely expensive and extremely complex. Yet thousands of people who have been able to either produce or retool them have found ways to do incredible things with them. For example, have you ever seen the movie Gravity? All the scenes where Sandra Bullock is flying through space are all shot using industrial robot arms.

My question to you is what would you do if you had access to these robot arms? What would you do if you could change them and shape them however you liked? And what would you make if you knew how to use them?

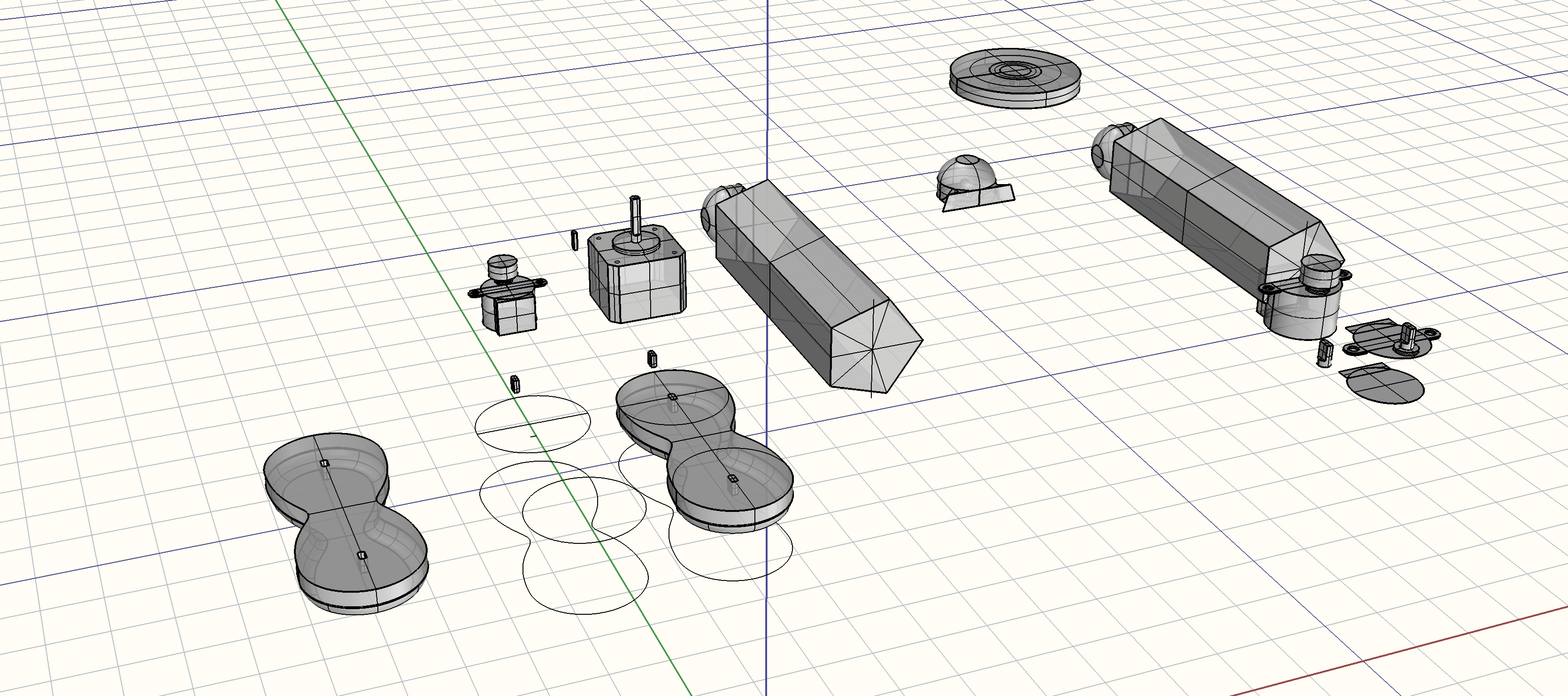

Let’s go explore that question. Let’s explore how to design, build, program, and then play with our own 3D printed robot arms. In the coming posts we will step through the process of modeling 3D parts using Computer Aided Drafting, or CAD for short. We will explore what kinds of parts we will need to build these robot arms on the cheap, and how to make sure that they are incorporated into the design.

After all the CAD work is done, we will 3D print our parts and assemble them. Later, we’ll still have to learn how to program and control the robot. After that, well, the sky’s the limit, and even though I will show you what I want to do with these robot arms, I am more excited to see what you do.

Let’s not get ahead of ourselves here though; first we have to design all the components. The very first thing we want to do in any project is get our materials.