Store-bought drawer organizers hardly ever fit my drawers. They’re not the same size as my drawers, nor are they as deep. So, they don’t actually organize all that well.

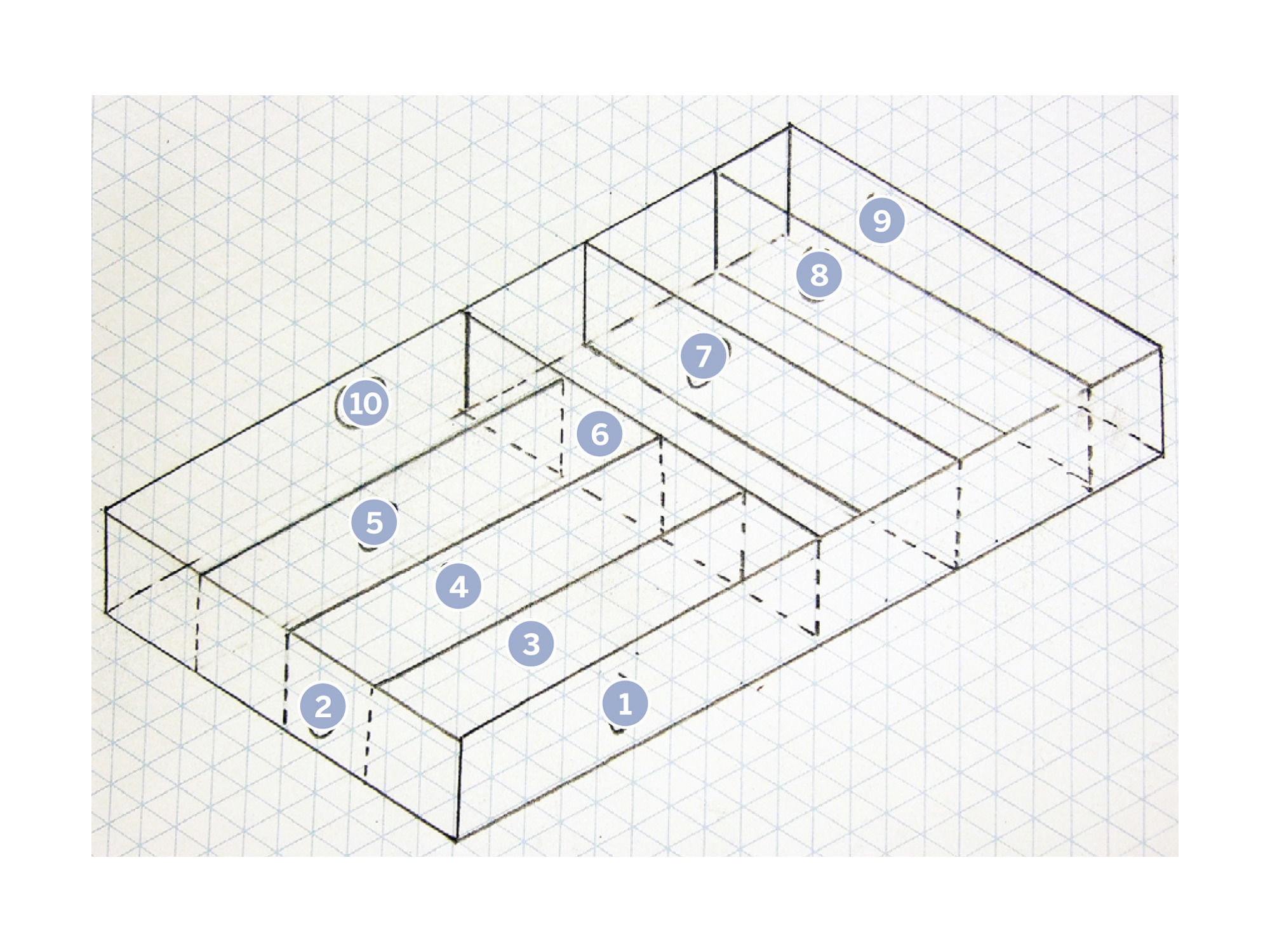

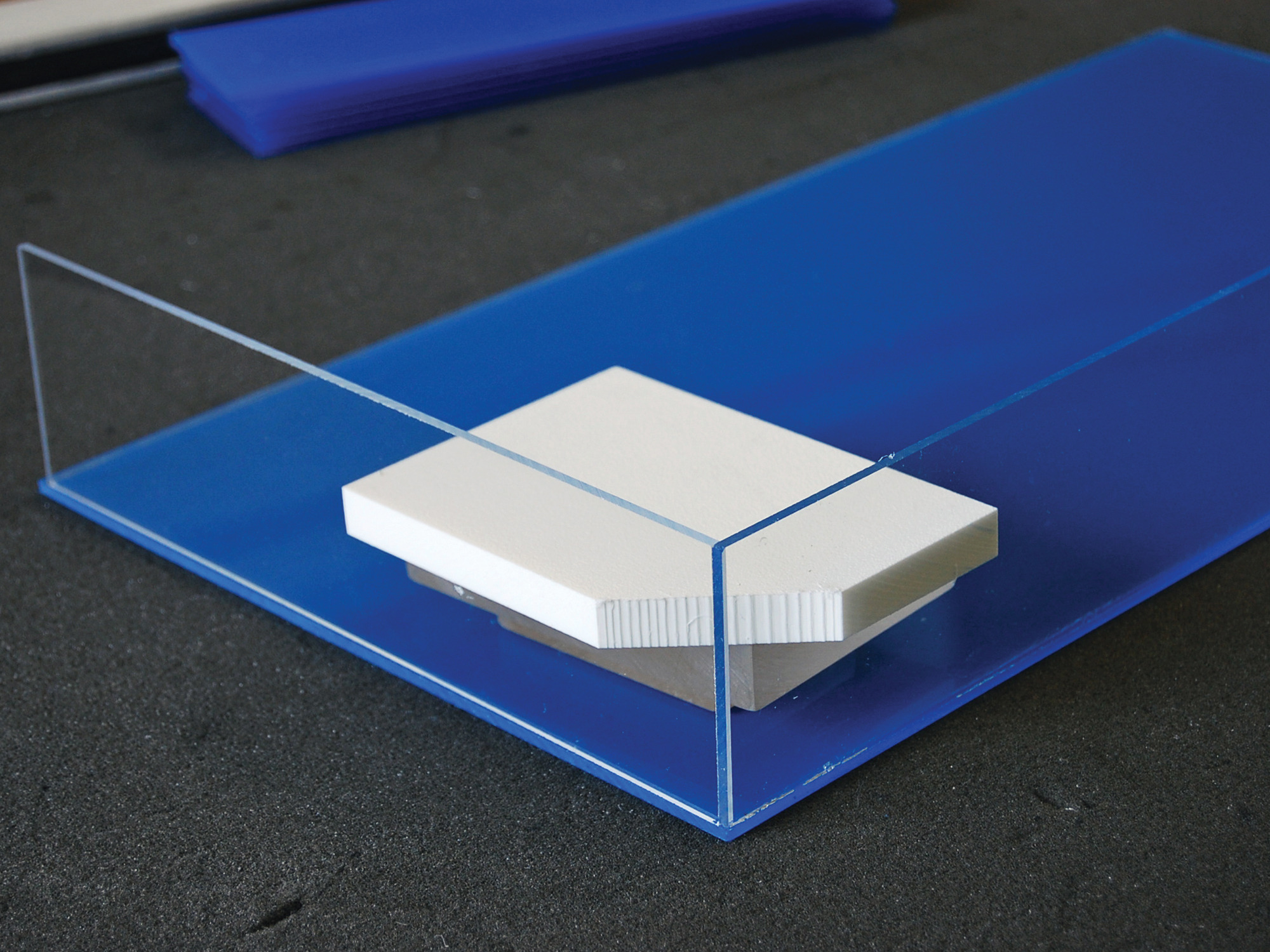

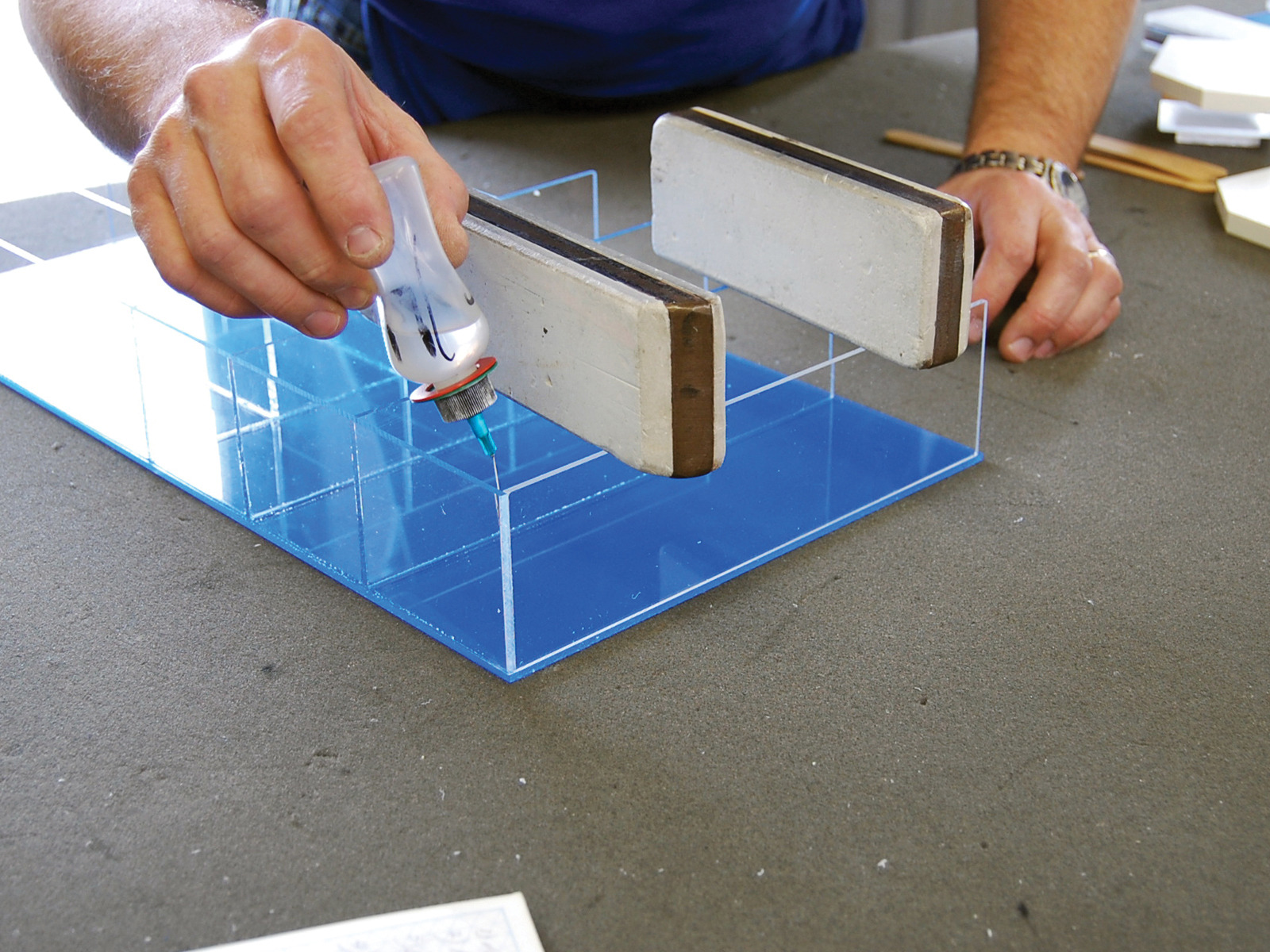

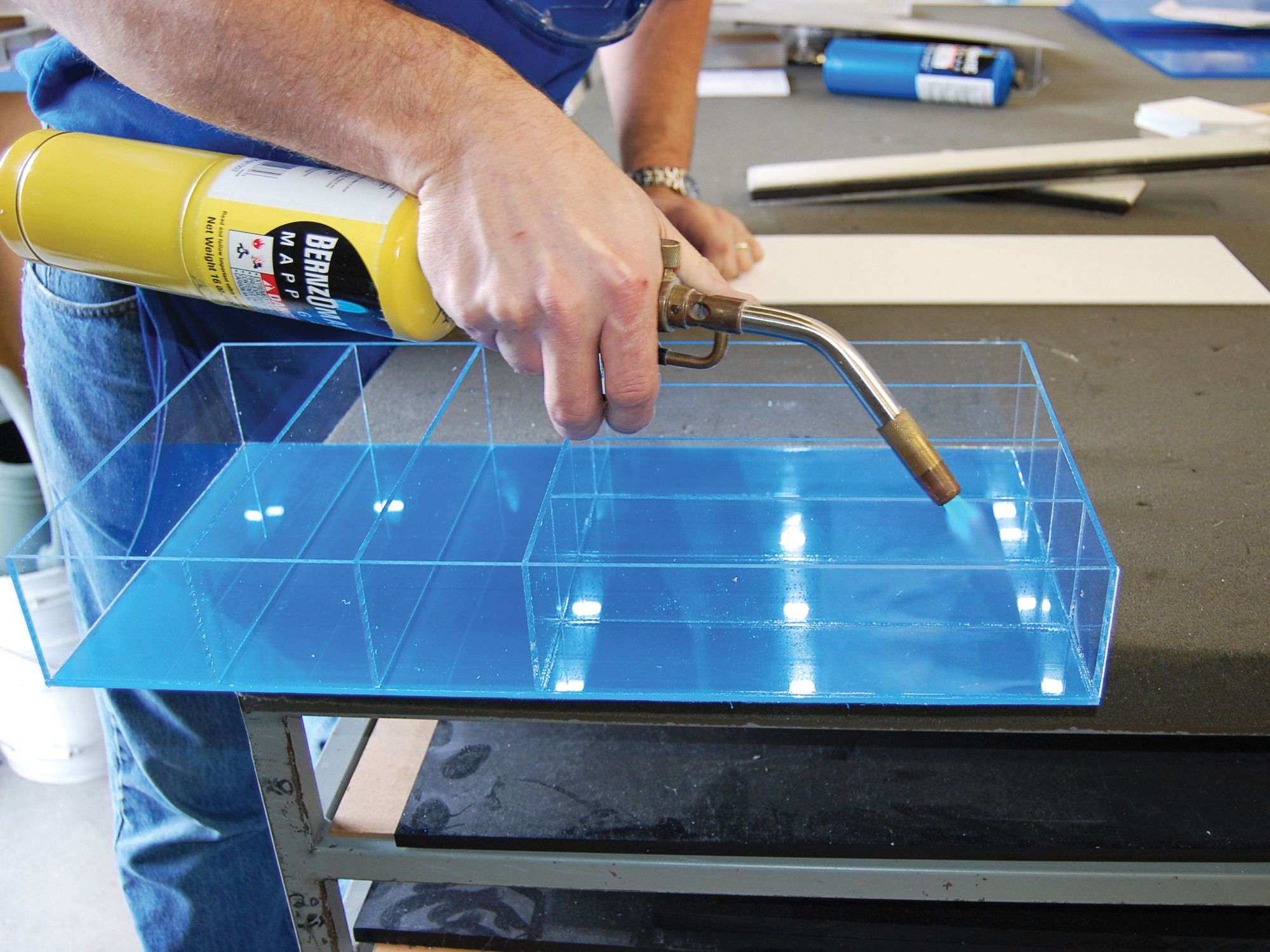

But it’s possible to make a custom drawer organizer for any drawer in your kitchen, workshop, or desk. Here’s how to do it easily and inexpensively.