An ideally energy-efficient house should be tightly sealed, to hold cool air inside during the summer and keep it out during the winter. The trouble is, we need to circulate some fresh air to remove odors, bring in oxygen, and reduce the risk of mildew and mold growth.

Is there a way to move air in and out of a house while minimizing the heat moving in and out?

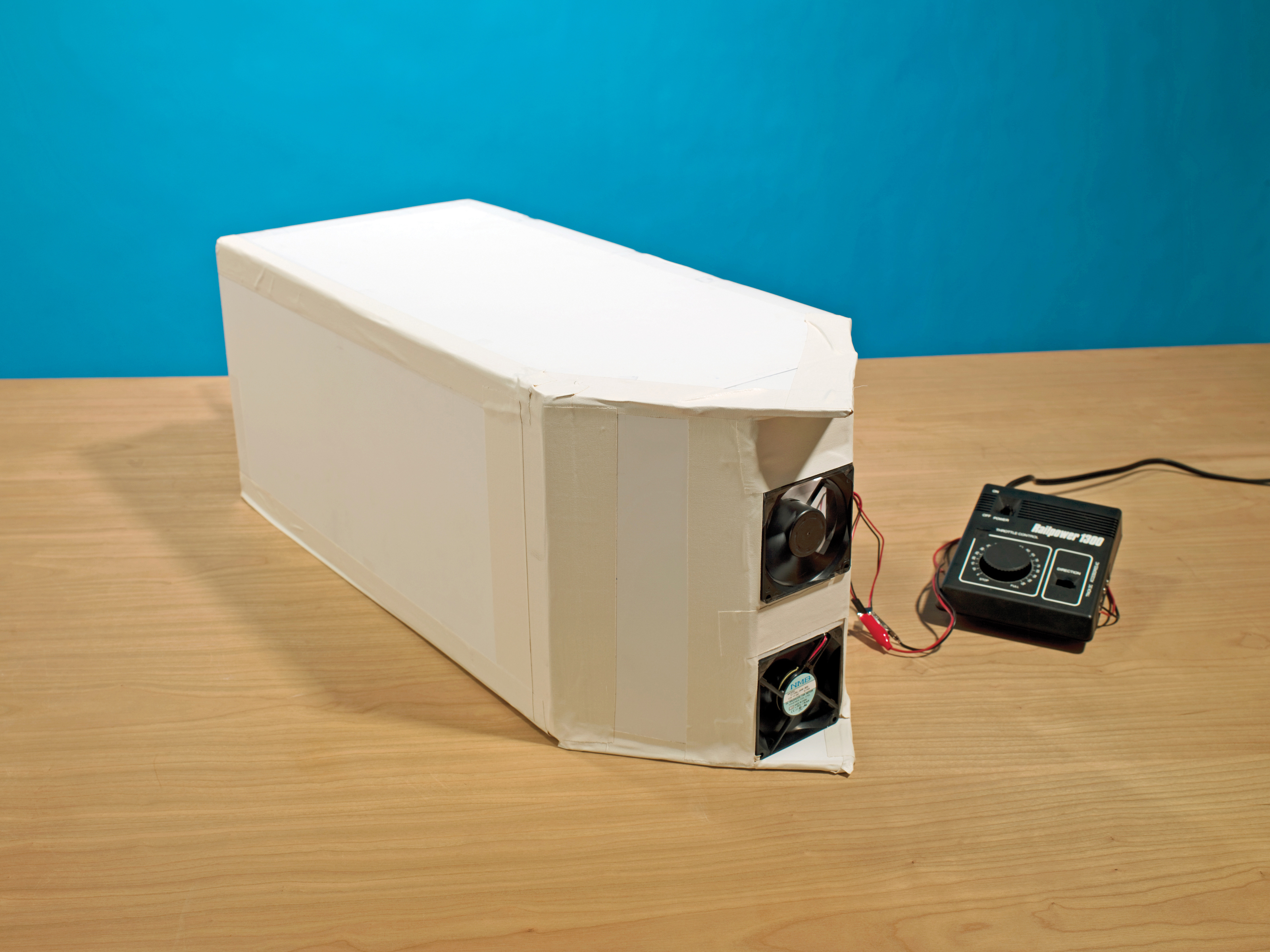

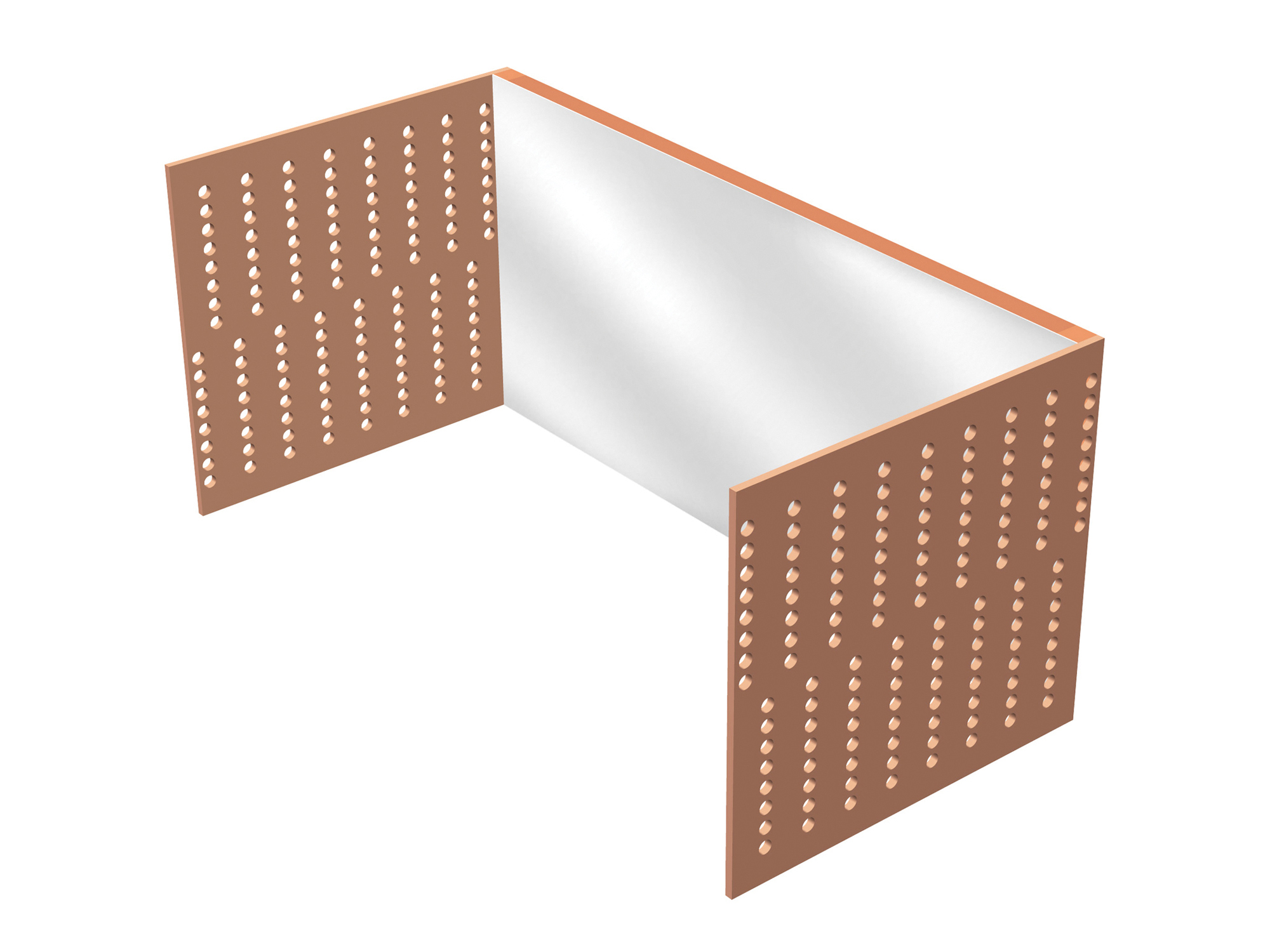

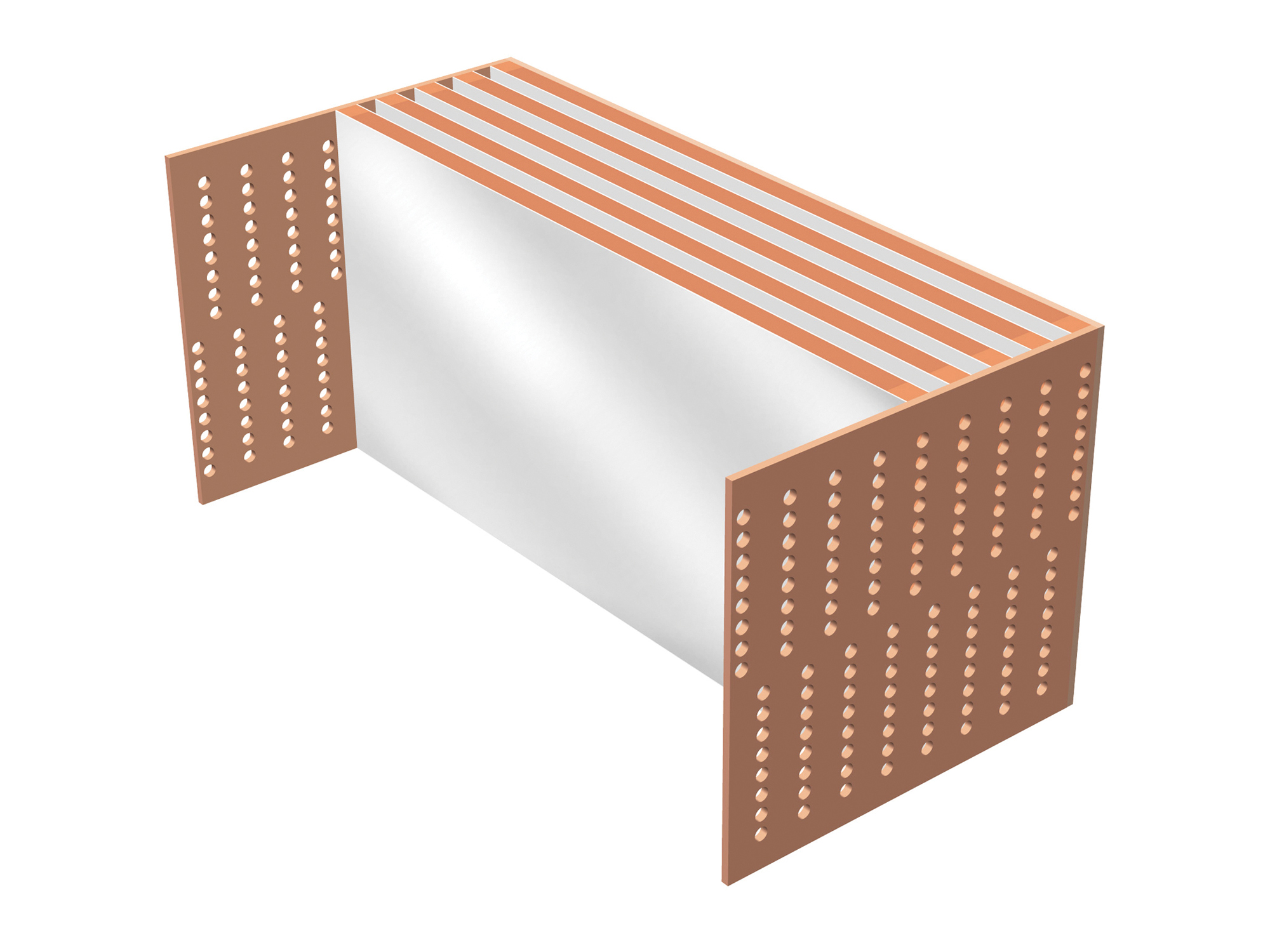

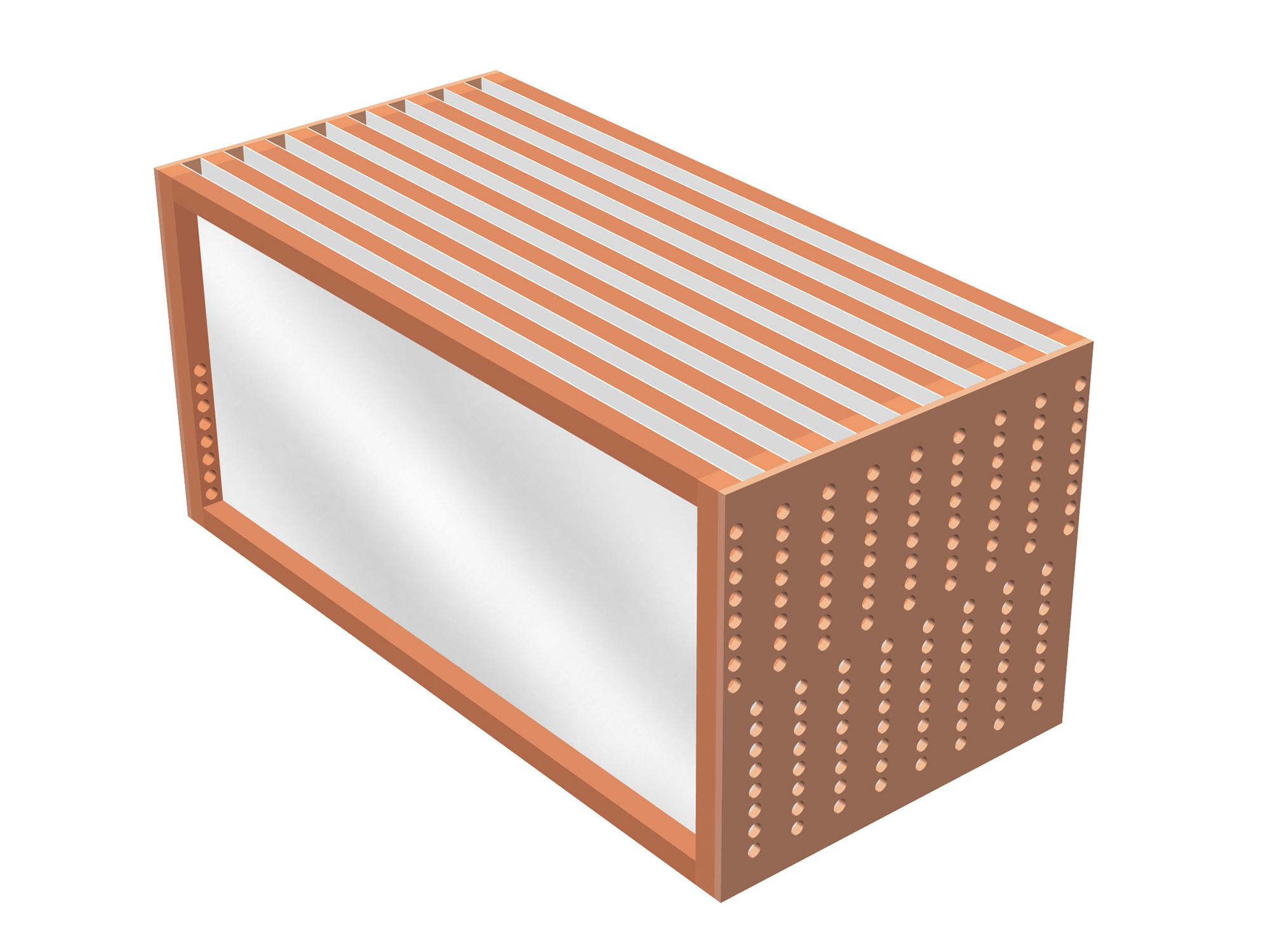

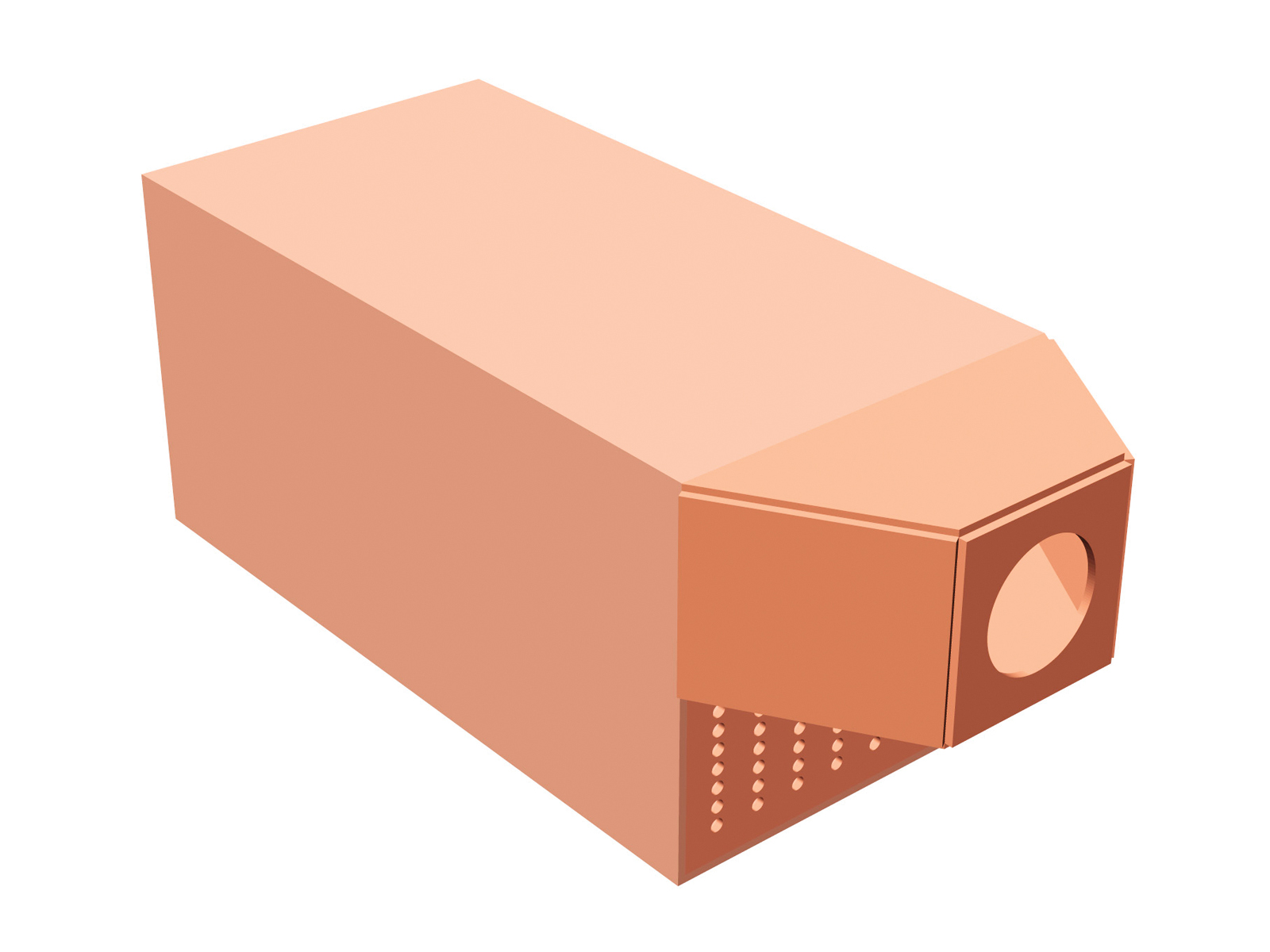

One simple gadget can do it: a heat exchanger, aka “heat recovery ventilator.” Instead of letting air run in and out freely, the exchanger uses two small fans to draw incoming and outgoing air through parallel interleaved ducts. The two flows don’t mingle, but heat passes between them through the thin metal walls of the ducts.

In the winter, warm air going out through the heat exchanger gives up its heat to cold air coming in, and during the summer, cool air blown out through the heat exchanger steals heat from hot air coming in, so that by the time the incoming air enters the house, it isn’t hot anymore.

Heat recovery ventilators are cheap to run, because they only contain a couple of fans. But they can be costly to buy, retailing for $450 and up.

Here’s how you can build your own for radically less, $50 to $100, depending on how many materials you already own. This is my first design attempt, and it works, but I don’t pretend that I optimized it. Feel free to make it better.

I am very grateful to MAKE intern Eric Chu for tackling the hard work of fabrication and testing, using plans that I drew.

Design

These are the crucial design features to get the most out of a heat exchanger:

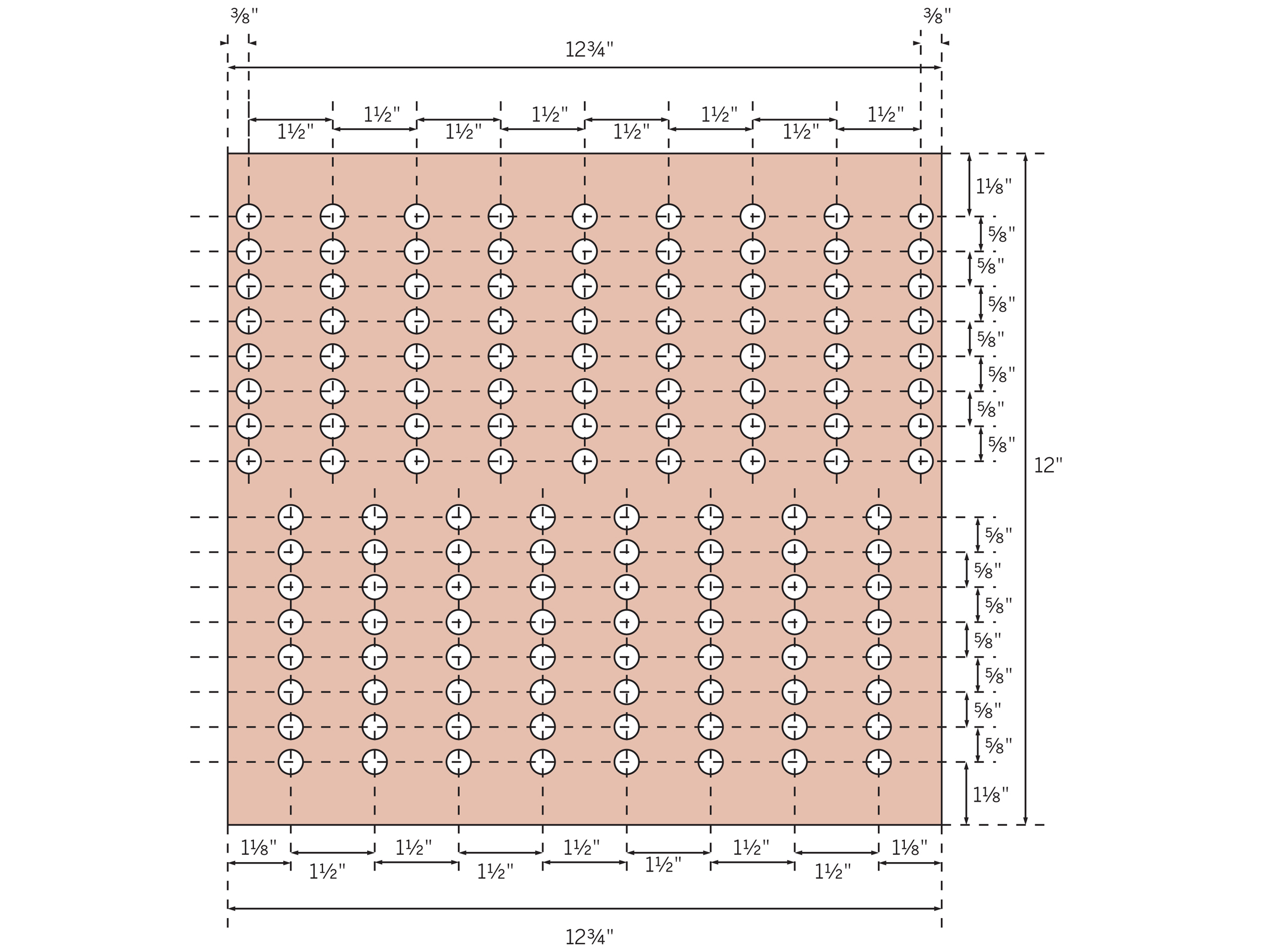

- Interior panels should have maximum surface area relative to volume.

- Panels should be made from thin, thermally conductive metal.

- Incoming air and outgoing air must move in opposite directions.

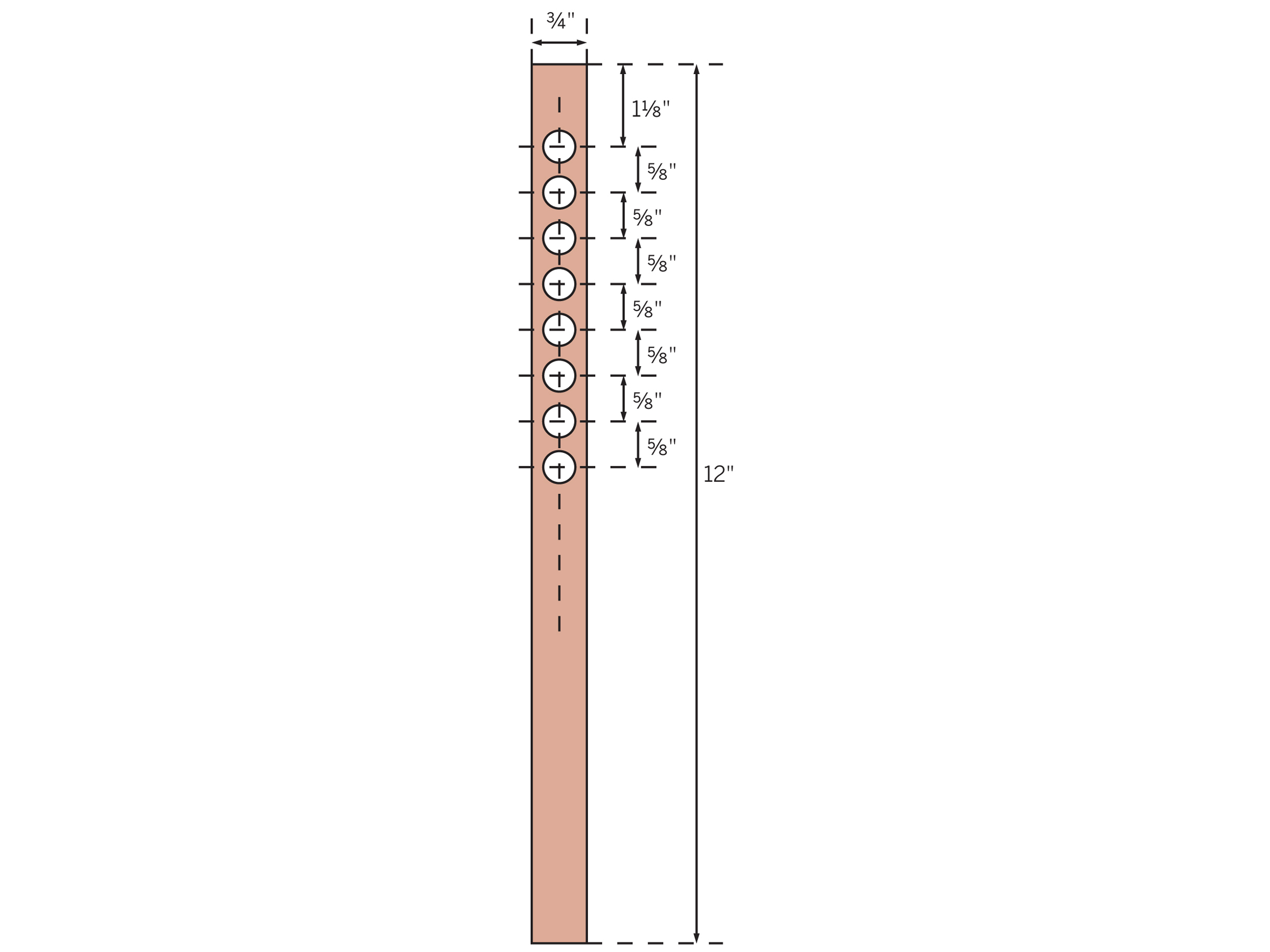

Since aluminum conducts heat very efficiently, I decided to make the panels from aluminum foil stuck to wooden frames, with holes drilled in the edges of the frames to allow air to pass through. Cheap computer fans are fine since they’re quiet and don’t use much power. Since this unit is merely providing some moderate ventilation rather than heating or actively cooling roomfuls of air, the flow rate can be low.

You might assume that slower airflow allows greater opportunity for heat transfer between air going out and air coming in. Theoretically, this should be true, but in practice other factors play a part, such as heat penetrating or escaping from the box containing the unit. When we tested our exchanger on the cold night air, we found that higher fan speeds actually warmed the incoming air more. Perhaps this is because faster-moving air lengthens the temperature gradient along the heat-transfer path and keeps the box containing the unit from getting cold.

Where, exactly, is the sweet spot? I suggest you build the unit and adjust the fan speed experimentally to find out.