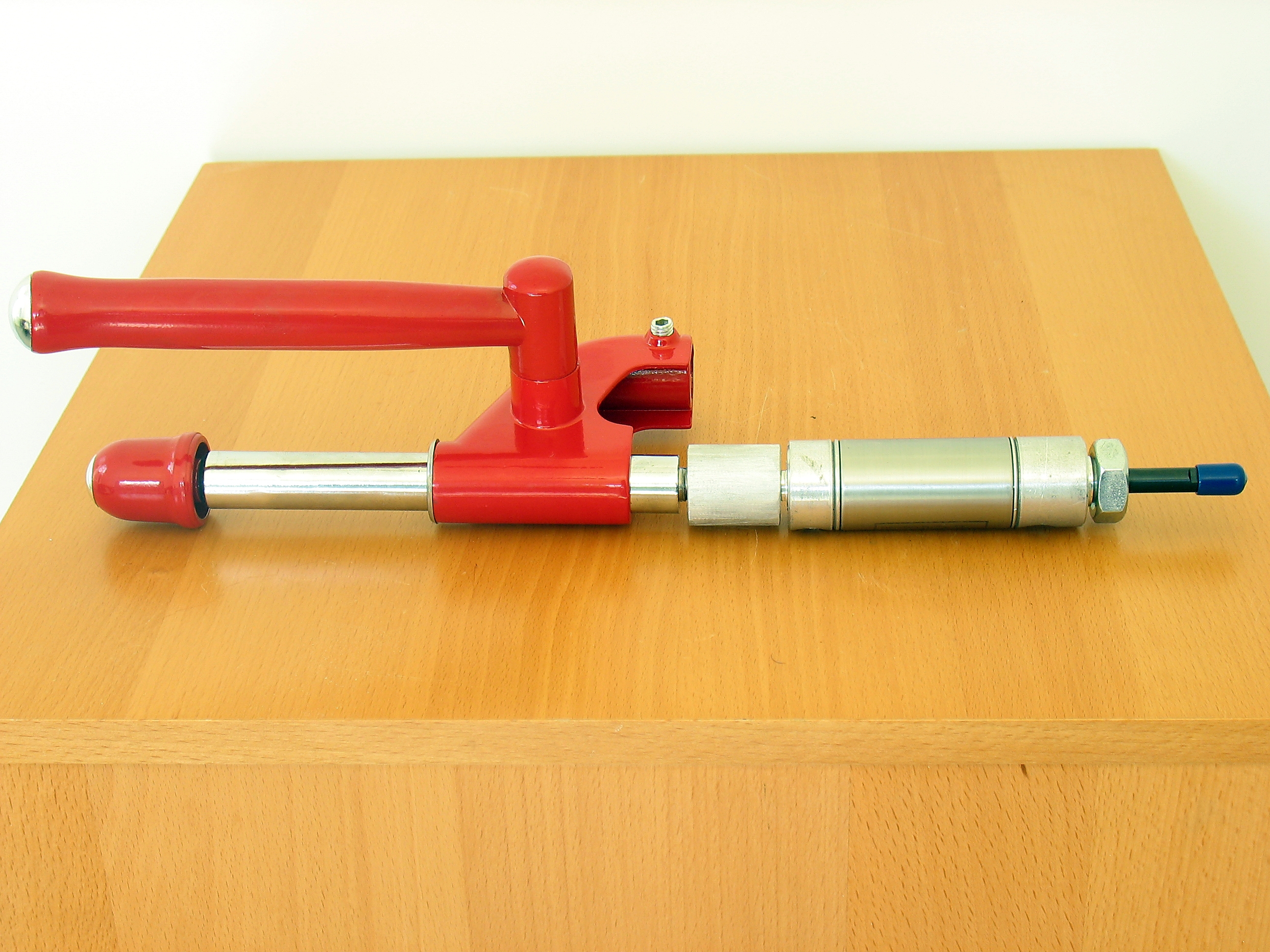

The variable I chose to attack was the problem of tamping. I’d heard about automated tamping systems, which remove the guesswork of manually pressing grounds into the portafilter with a handheld tamper, and instead consistently provide 30 pounds of uniform pressure. This is great, but automatic tamping machines cost hundreds of dollars. One clever member of the http://www.home-barista.com forums scoffed at the price tag and built his own, using a manual lever juicer as the platform. I decided to give it a try.

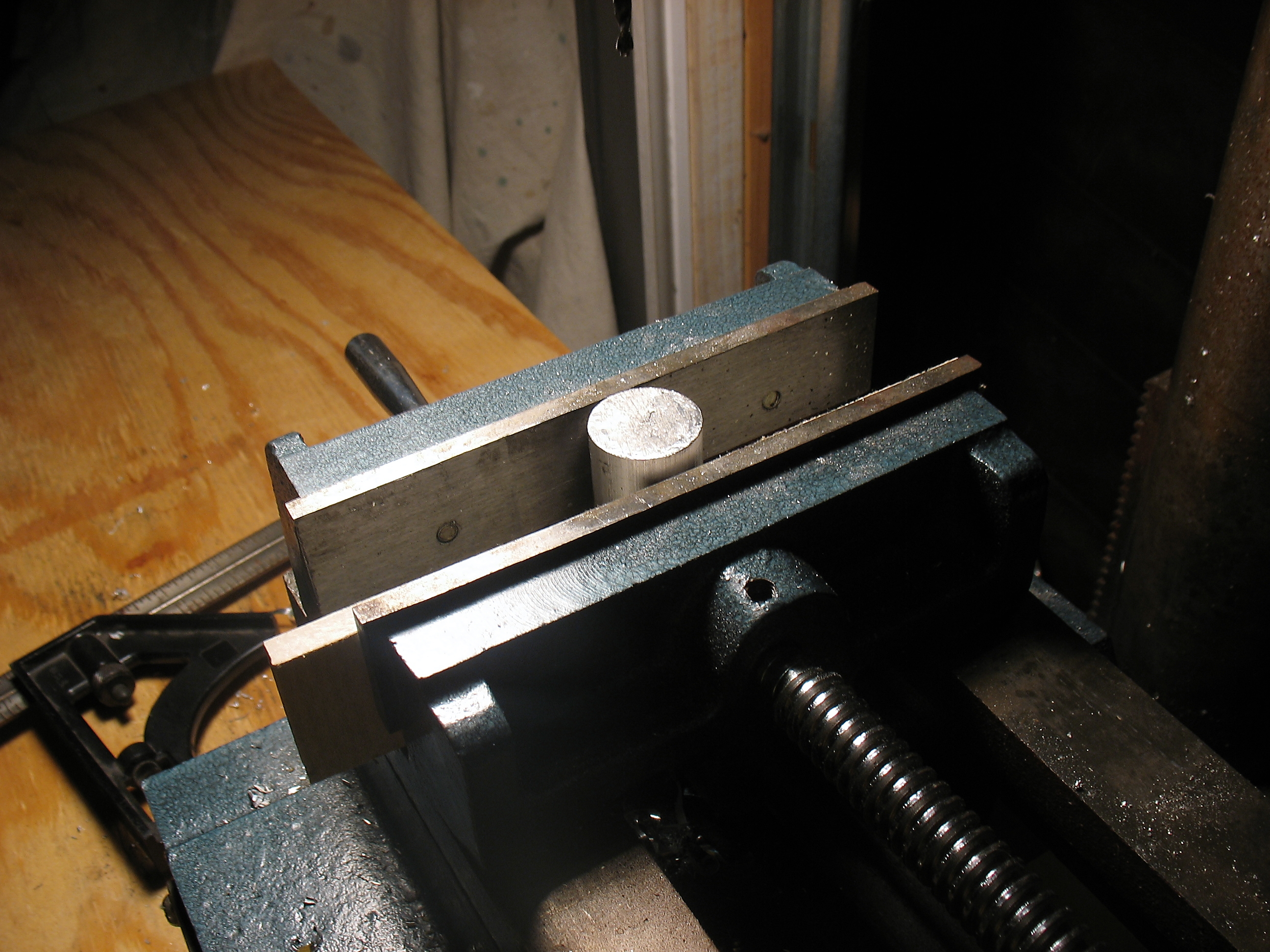

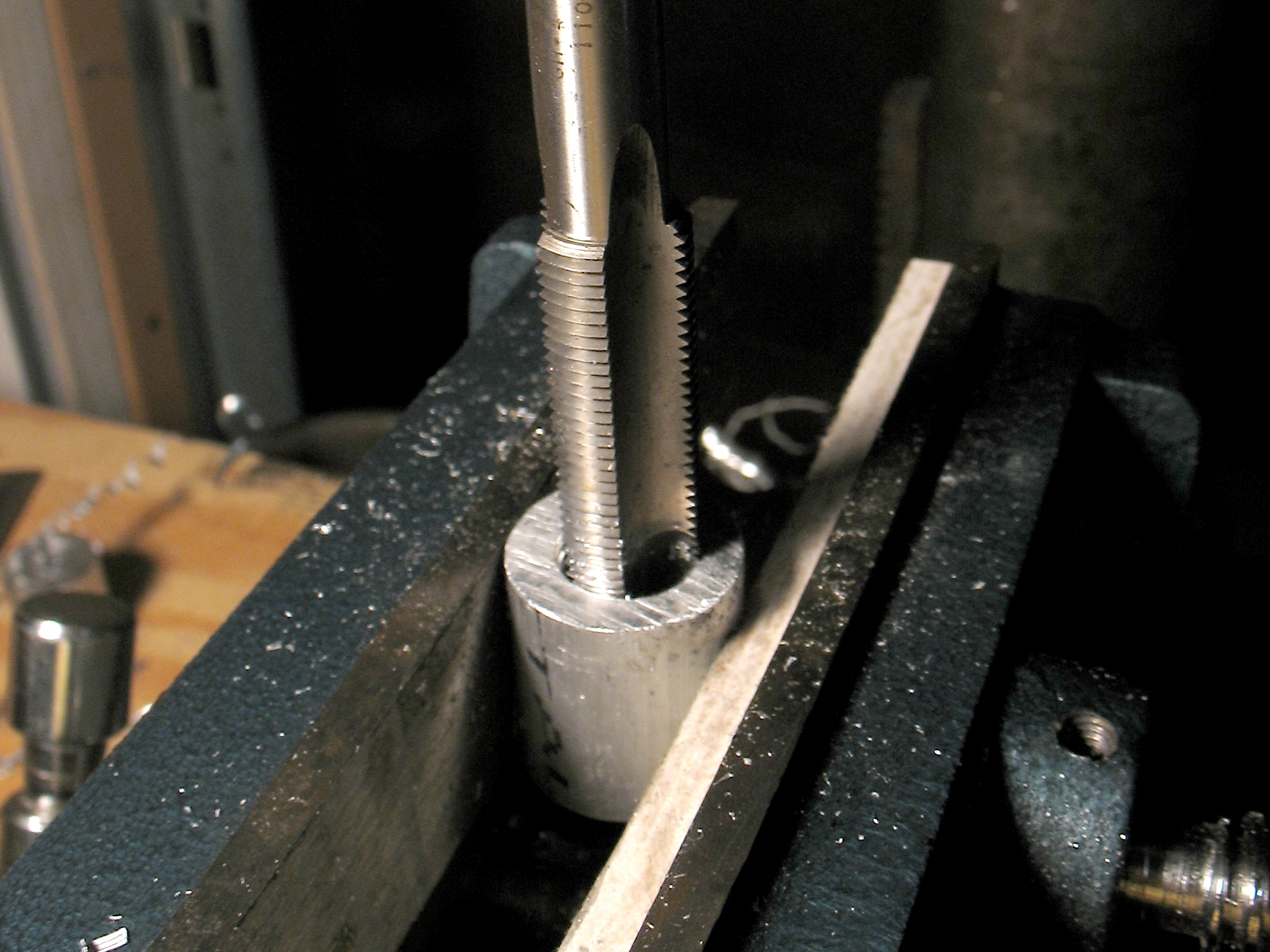

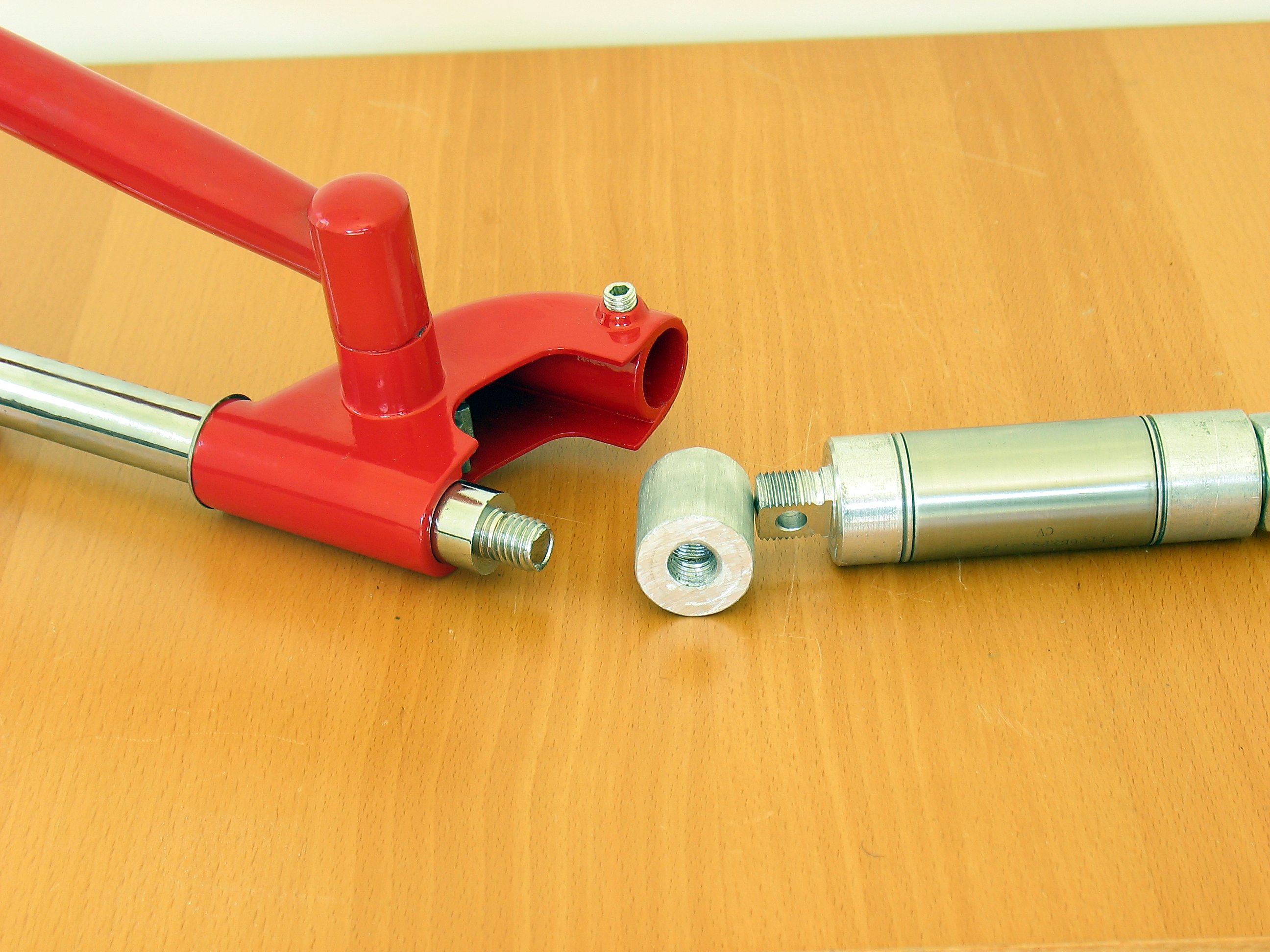

I considered a few requirements for my auto tamper: a way to know when I’ve hit the magic 30lbs, a way to secure a commercial tamper base to the down-shaft of the juicer, and a method of resting different portafilters with their oddly shaped undersides on a load-bearing surface.

Through some informal research, I determined that the most common method of indicating correct pressure in a commercial auto tamper is with a “clicker” system. This is a calibrated spring and ball bearing mounted at a right angle to the shaft. One great feature of these systems is that they stop all downward pressure after the threshold has been met.

Home baristas have more commonly opted for a heavy spring mounted over the juicer shaft, kind of like a car’s coil-over suspension. Enlisting the aid of a bathroom scale, they test for the 30lb depth and then mark a calibration line on the shaft. This is an elegant, simple design, and they’ve reported excellent results. Another simple method, suggested by a gearhead friend of mine, would be to replace the lever handle on the juicer with a torque wrench adjusted to pop when 30lbs are measured at the tamper.

While the torque wrench would have functioned well, I was also concerned with aesthetics. I wanted to maintain the quasi-steampunk look of my espresso machine, with its beautiful pressure gauges front-and-center. I wondered how I could use an analog dial to read out my tamping force. After another brainstorming session with my friend, we had it: a pressure gauge connected to a hydraulic piston coupled between the juicer’s down-shaft and the tamper base.