Projects from Make: Magazine

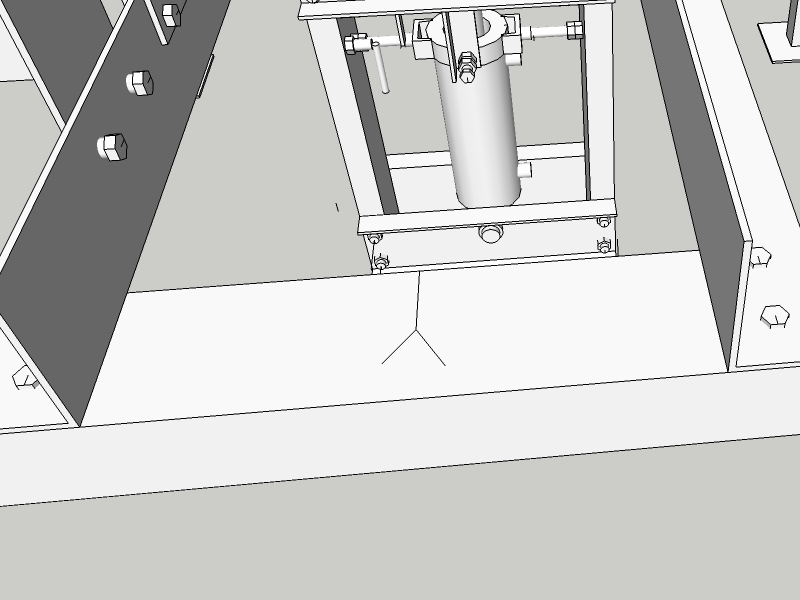

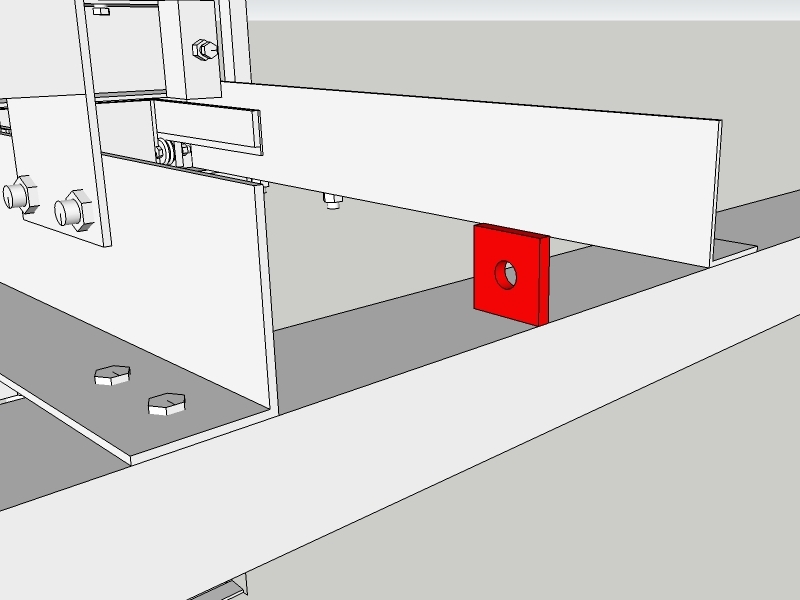

Installing the Secondary Cylinder

This guide explains installing the secondary cylinder. This is to be done after you have assembled the structural components. It is recommended that this be the last part of assembly, as it could get damaged if its not.