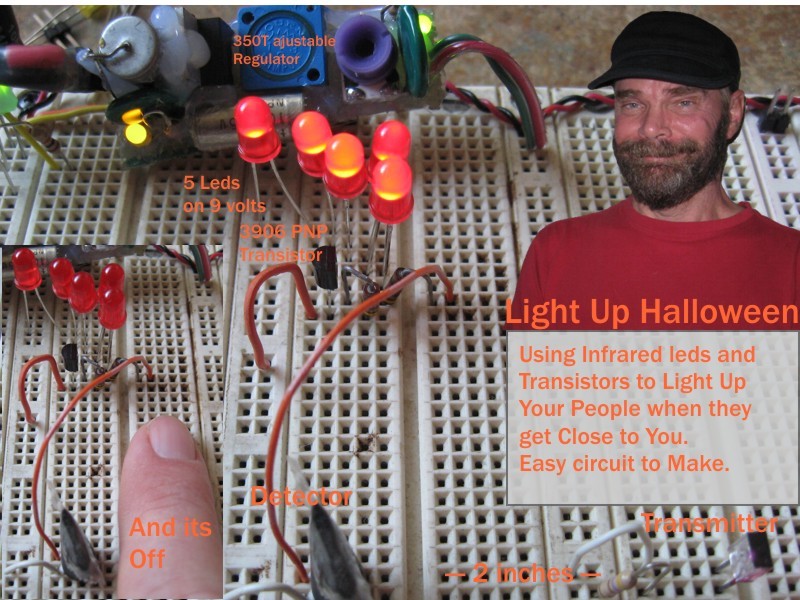

You can use infrared diodes to light up your people when you get close to them. When your transmitter activates their detector their lights light up, and their transmitter lights up yours. When someone touches your magic spot (your detector) your spot lights up and their thing lights up. It is simple and easy to do with transistors. Transistors rule our world. I will show you how to light up your people with transistors.

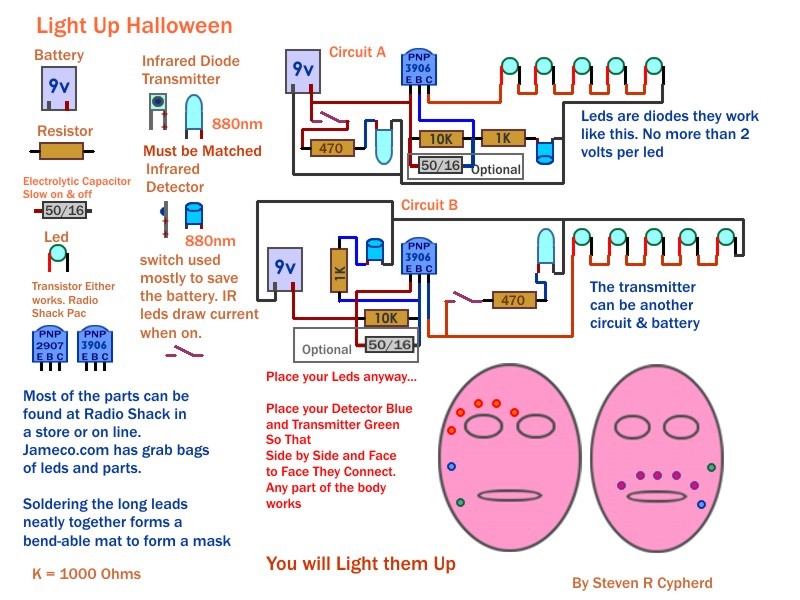

The first thing you need is parts. Soldering is the best way to make things you can play with. RadioShack still sells transistor packs in PNP and NPN varieties. PNP amplifying transistors (15-pack) are part #276-1604. RadioShack NPN Transistors (15-pack) are part #276-1617. Usually you get about four types of each. I am using PNP transistors in this circuit. You can use any of the types of PNP transistors in this pack. Either the 2907 or 3906 work well here. The next part you need is a good infrared emitter and detector pair. They are sold in wavelength (measured in nanometers, nm) and you must match them closely to get them to work.

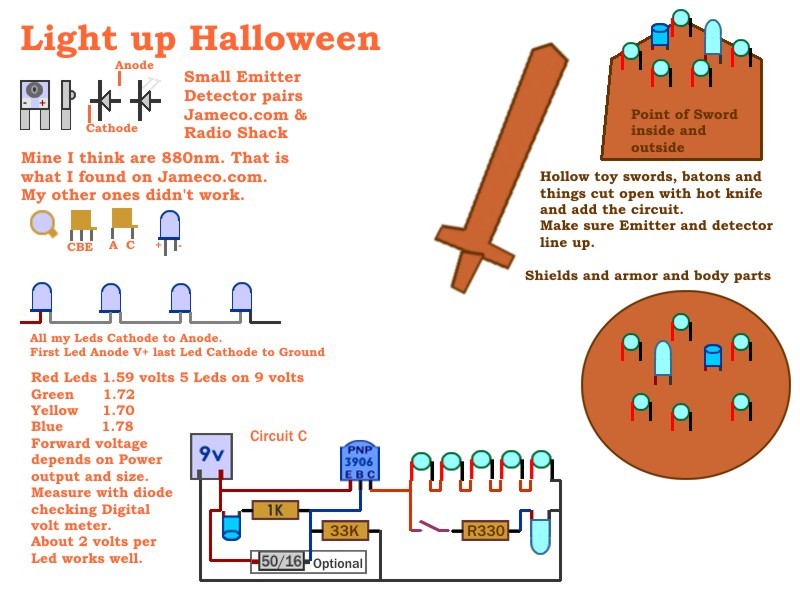

Out of all the parts I have tried, the infrared 880nm emitter and detector pair are the ones that worked best for this circuit. They are the little side-shooter two-lead type. The transmitter is the 880nm emitter diode. The detector is the photodiode (or phototransistor or photo Darlington) in 880nm. Jameco is the best place to get all of the parts. I included the PDFs. Use the term ‘Infrared’ to search Jameco.com for these devices. You only need enough power to cross about two inches. All infrared devices work best in the dark. Most devices in the range 800nm to 1050nm will work together. The little side shooter two lead types have very narrow bream.

Jameco.com has packs like RESISTOR, 610 PACK E12-SERIES 1/4W 5% TOLERANCE (part #2131039), hook-up wire in a 10-Color Stranded Wire Kit Assortment (part #2130917) and 1900 LEDs T1 AND T3/4 ASSORTED COLORS AND SHAPES LED GRAB BAG (part #135271). For a good soldering station I have the MakerShed’s Variable Temperature Soldering Station. If you do more types of crafts, a woodburning kit that has a soldering tip and hot knife may be a better tool to have. I can’t live without my mini toothed pliers, mini sharp diagonal cutters, my standard aluminum body X-Acto knife and my mini hot glue gun.

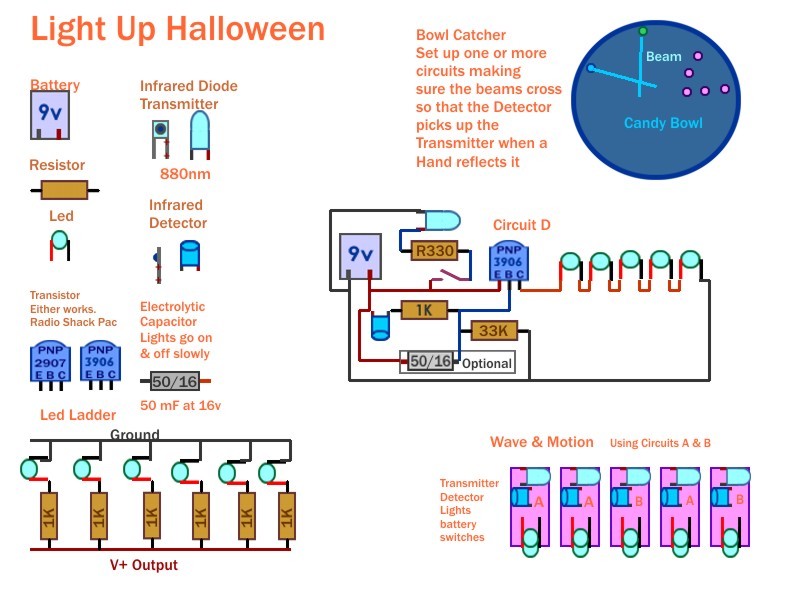

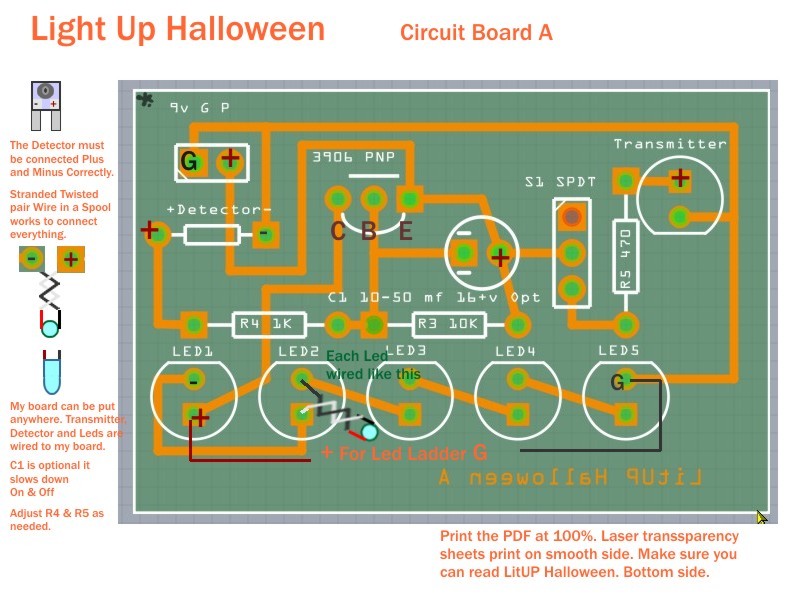

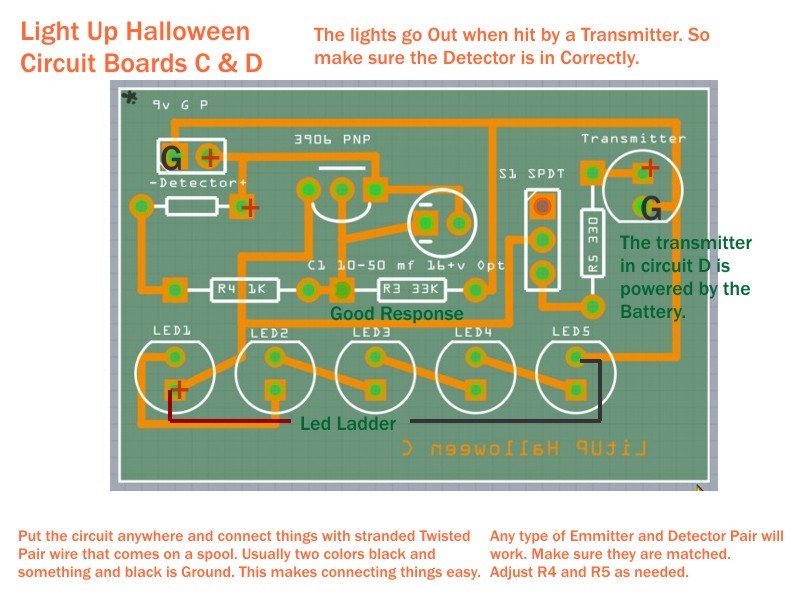

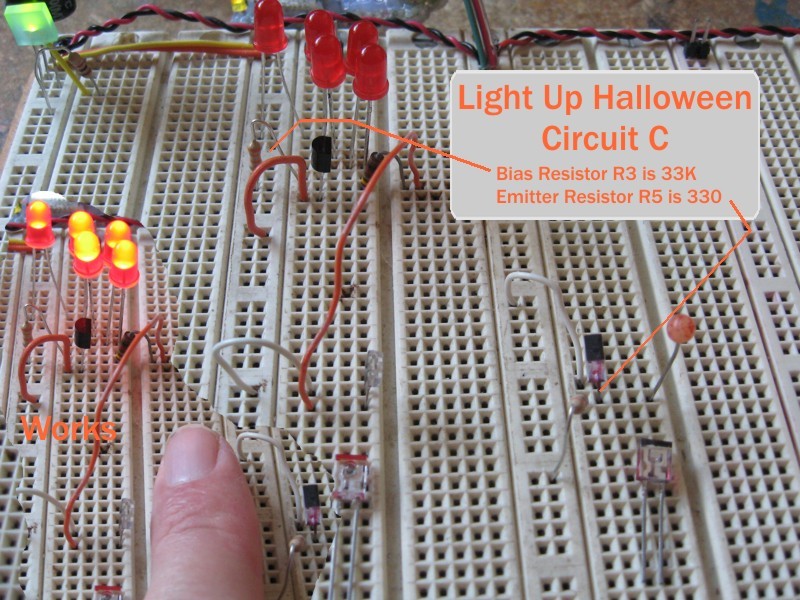

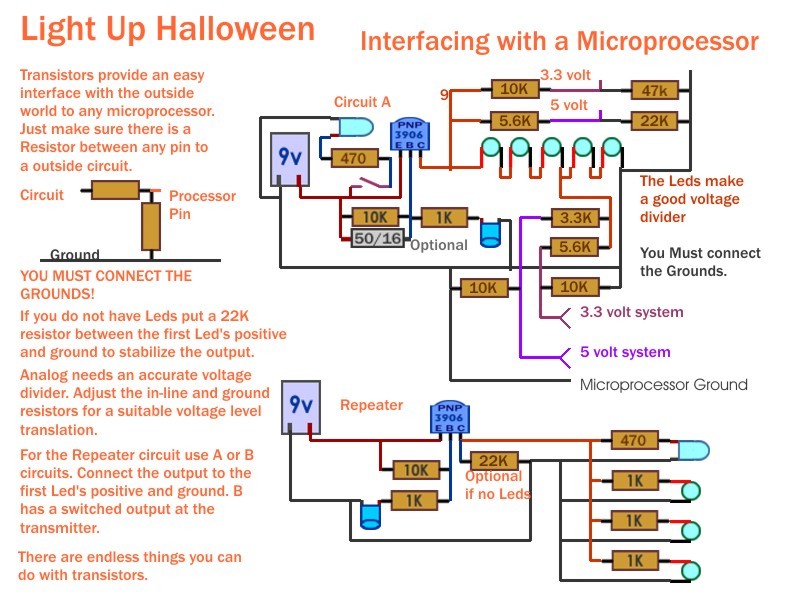

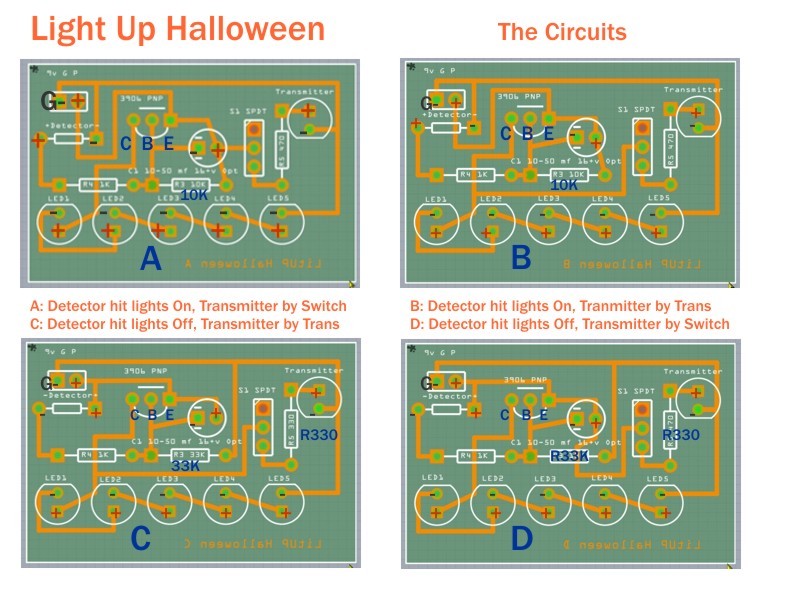

The circuit is simple. When the detector gets illuminated by a transmitter its resistance lowers. This brings the base of the PNP transistor more negative and it turns on and your lights light up. The 10K resistor connected between V+ and the base of the PNP transistor biases the transistor off. The transmitter can have its own battery and a switch. They use the most current when they are on. When you are near to your people switch your transmitter on. I made this a 9-volt circuit so it is easy to make and have fun with.

Because the power supply is 9 volts use a 330-470 resistor on your transmitter. Infrared diodes come in different power outputs. See how close you have to be to turn on your lights and adjust the resistor’s value until the circuit performs the way you want it to. Resistors are measured in ohms. 470 is 470 ohms. 1K is 1000 ohms. 10K is 10,000 ohms. You may notice that I have no resistors on my LEDs. LEDs are diodes. Diodes in series divide the supply voltage between them. Diodes have a forward voltage which can be measured with a digital voltmeter set on “Diode.” Red LEDs have the lowest forward voltage and yellow and blue have the highest. The size and power of the LED will determine its forward voltage. Measure them and add up your LEDs to see how many you can put in series with your supply voltage. I can put 5 Red LEDs in series on a 9-volt supply. LEDs need about 2 volts to operate. One too many LEDs and the lights go out.

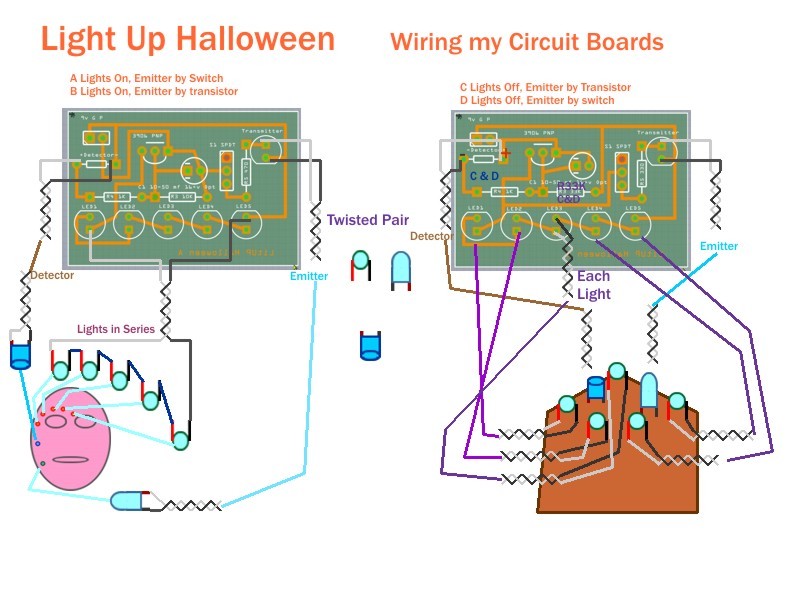

In the A & B circuits the lights turn on when the Detector is hit by a transmitter. In the C & D circuits the lights turn off when the Detector is hit by a transmitter. In the B & C circuits the transmitter is powered by the transistor when the Detector is hit by a transmitter. All of the transmitters have switches. I did not have friends to build this for. I should have done more work on the C & D circuits before I uploaded the article. It is a very simple circuit. I found errors in the ten PDFs and I replaced all of them. Sorry I pushed Fritzing too hard.

Making the boards is easy. Positive resist boards, positive developer, etchant and exposer lights are available at Jameco.com. Print the PDF files at 100%. For laser printers print transparency sheets on the smooth side and ink-jet on the rough side. You can cut PCBs with a light duty metal sheet cutter.

Etching solution is ammonium persulphate at 250 grams to 1 liter of water. 125 grams 15 ounces water. Keep etchant warm. Developer is Positive Type P.C. 1 part to 10 parts water. 1.5 ounces to 15 ounces water. Use plastic trays and bottles. The switch I found on Jameco.com SPDT PC mount standard is 3mm spacing and my board is .1in. Drill the lower two holes 5/34 and the first hole a little bigger .039. Use .035 most holes and .037 for a little bigger.

To work with Fritzing you need electronics knowledge and desk-top publishing experience. An example is the Object Label used in all views. Right-click the object and select Show Label. Select the object and left-click the label and drag it. Right click the label and select Edit, Size, Rotation and Display Details.

You must get the breadboard and the schematic perfect before you can make a good PCB. Avoid “birdcage wires” (Fritzing calls them “rat’s nest” wires). Test all circuit paths by clicking on a node. Then in the PCB remove any rat’s nest wires, rotate and move the parts and delete and make new circuit paths. After it looks OK then use Auto Routing. You make big changes in the breadboard first then the schematic if you need it and then the PCB.

To make multiple circuits on one PCB, save your project as somethingA10. In PCB view click the PCB and in Parts set Sticky to unchecked. Click and drag the PCB away from your circuit. Set your PCB to the size that you need. A 4″x6″ board is 101.6mm wide and 152.4mm high. Drag a selection box around your circuit. Let go. Edit Duplicate the circuit (Ctrl-D). Wait for the duplicate circuit to show up. Do not click it. Use the arrow keys to move your duplicate onto your PCB. Repeat this for each copy. The breadboard and schematic will be a mess. Line things up nicely. Save your project. Make an editable PDF. Wait for it. Done. I do not put Sticky back on. Watch out for Duplicate errors when making multiple copies in one PCB of the same circuit. Look at the labels; they are label plus copy number. Do not touch the breadboard or the schematic.

Have fun.