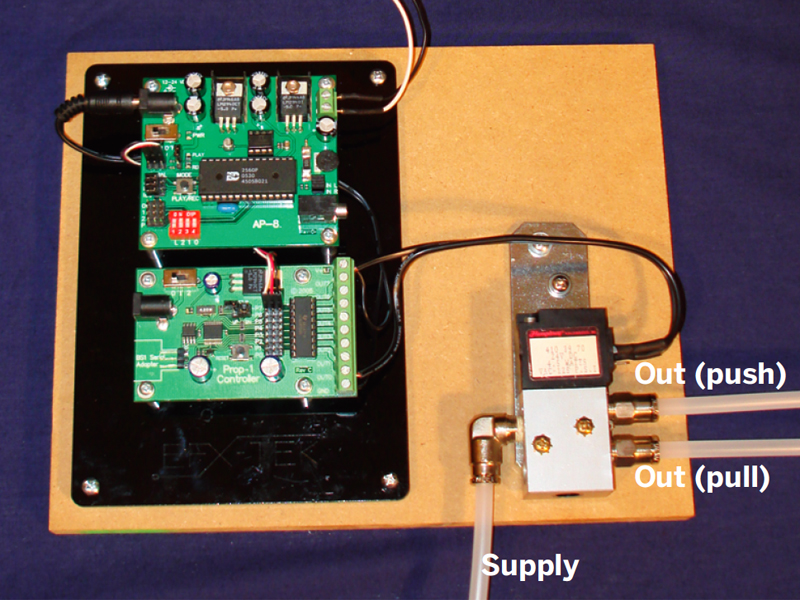

My friend John found this really great Chucky doll on eBay and had an idea for a mini electric chair. With the help of our friends Jeremy, Terry, and Karmyn (pictured with Chucky), we created an automated prop that we call Chucky Fries. With the addition of a simple controller, audio player, and second-hand pneumatics, we created a shockingly entertaining Halloween display. Chucky shakes, thrashes, and laughs-and survives the ordeal ready for the next set of trick-or-treaters.

Projects from Make: Magazine

Mini Electric Chair

How to electrocute the devilish Chucky doll of slasher movie fame.