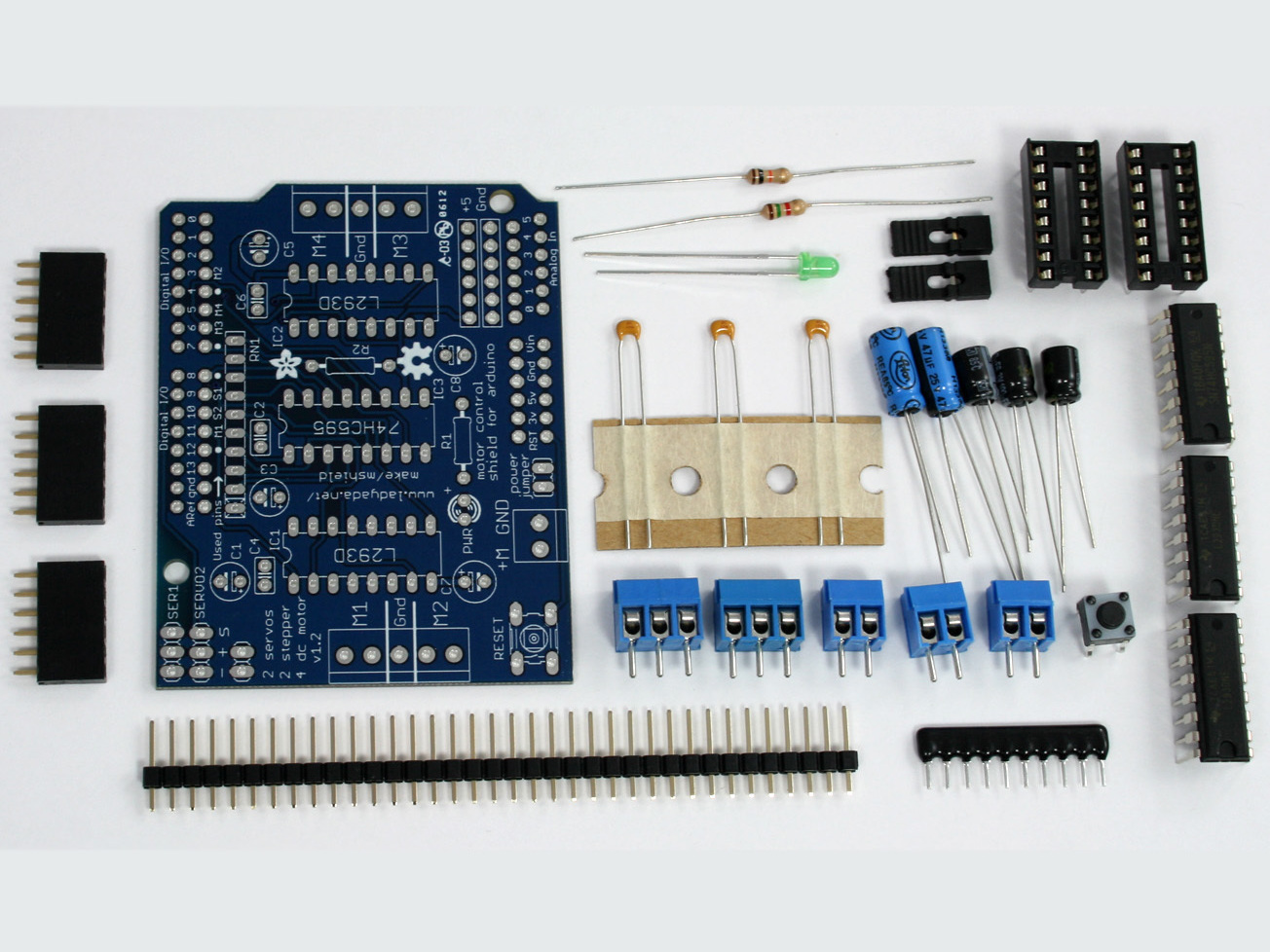

Arduino is a great starting point for electronics, and with a motor shield it can also be a nice tidy platform for robotics and mechatronics. The MAKE MotorShield Kit, designed by Adafruit Industries in partnership with MAKE, is a full-featured motor board that can power many simple to medium-complexity projects. It’s got:

- 2 connections for 5V “hobby” servos connected to the Arduino’s high-resolution dedicated timer — no jitter!

- Up to 4 bi-directional DC motors with individual 8-bit speed selection (so, about 0.5% resolution)

- Up to 2 stepper motors (unipolar or bipolar) with single coil, double coil, interleaved or micro-stepping

- 4 H-bridges: L293D chipset provides 0.6A per bridge (1.2A peak) with thermal shutdown protection, 4.5V to 25V

- Pull-down resistors keep motors disabled during power-up

- Big terminal block connectors to easily hook up wires (10–22AWG) and power

- Arduino reset button brought up top

- 2-pin terminal block to connect external power, for separate logic/motor supplies

- Tested compatible with Arduino Mega 1280 and 2560, Diecimila, Duemilanove, and UNO

Get your MotorShield kit from Maker Shed and build it in a couple hours, following the instructions here.

Then download the easy-to-use Arduino software library and you’re ready to go!