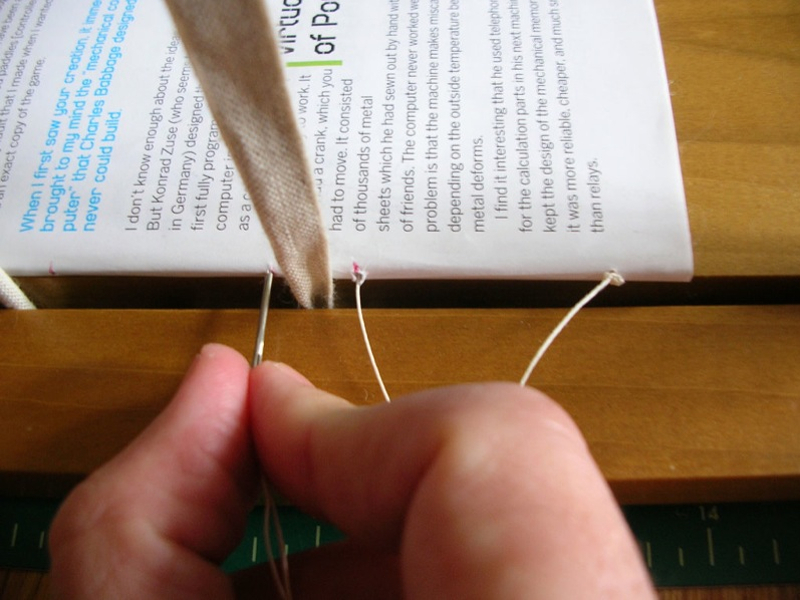

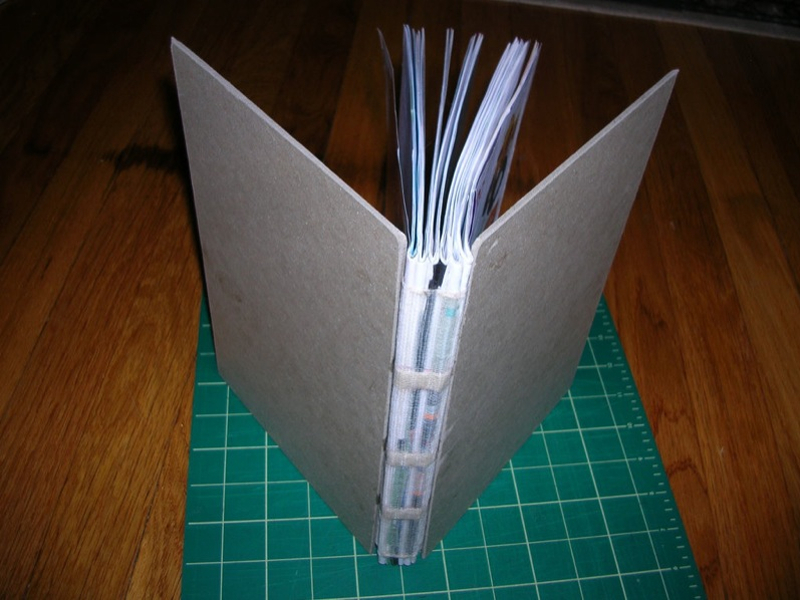

You’ll now cover this skeleton with a single piece of decorative paper, which wraps around the front cover, back cover, and spine. To create room to slide the paper over the edges of the cover and spine, use your utility knife to slit the mull by 1⁄2″ where the covers meet the spine, at both the head and foot edges.

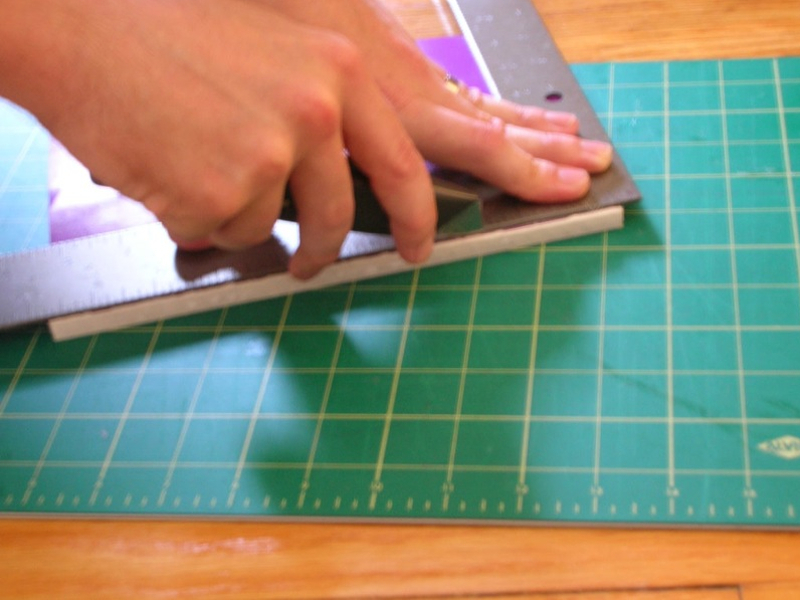

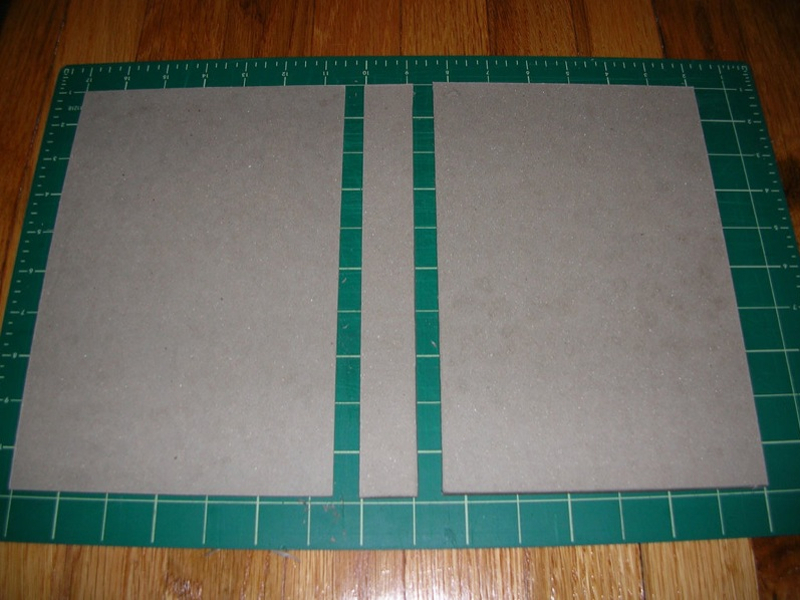

Lay your cover paper face down and mark the placement of your boards. Allow a 1⁄2″ (thickness of four boards) turnover width for all edges, and 1⁄4″ (thickness of two boards) for each hinge.

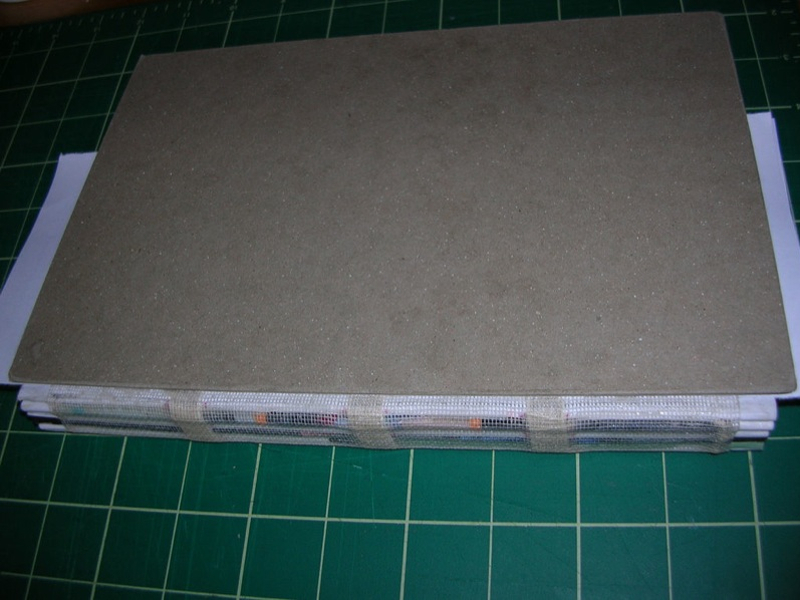

Brush the spine area of the paper with glue, position the board, and press firmly. Turn the paper over and rub to secure the spine and mold the paper over the edges of the board.

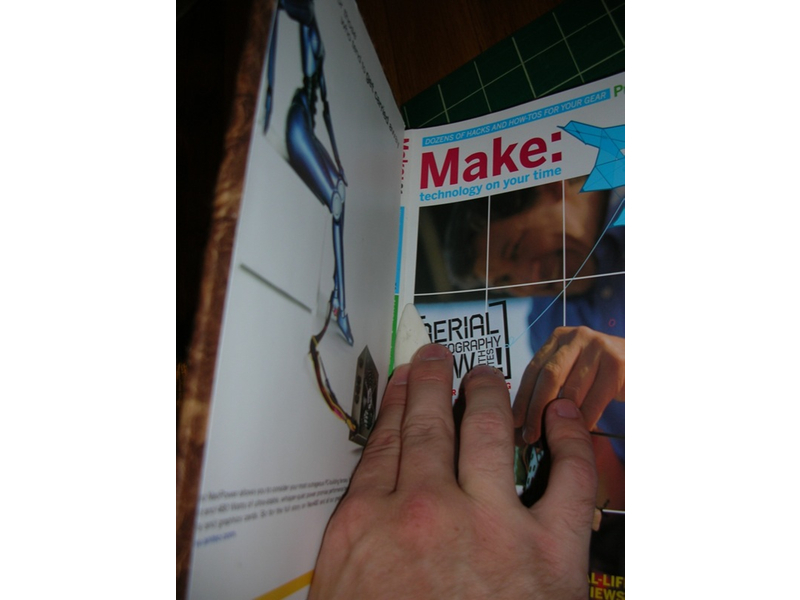

Brush the area you’ve marked for the front cover with glue, brush slightly into the turnovers and hinge, and press the board between your marks. Turn the book over and rub the cover to remove air bubbles or wrinkles.

Brush glue onto the area for the back cover. Lay the back cover board’s fore edge down on the paper, meeting your mark for that edge. Pinch the paper to the board on that edge, and press the remaining paper to the back of the book.

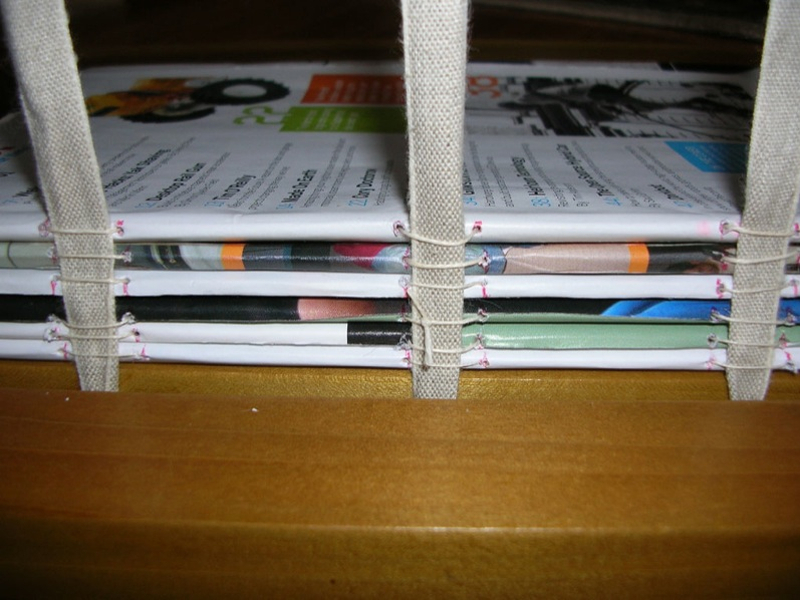

Rub the back cover, working the paper on into the hinge to seal the paper to your book block around the spine. Repeat for the hinge of the front cover.

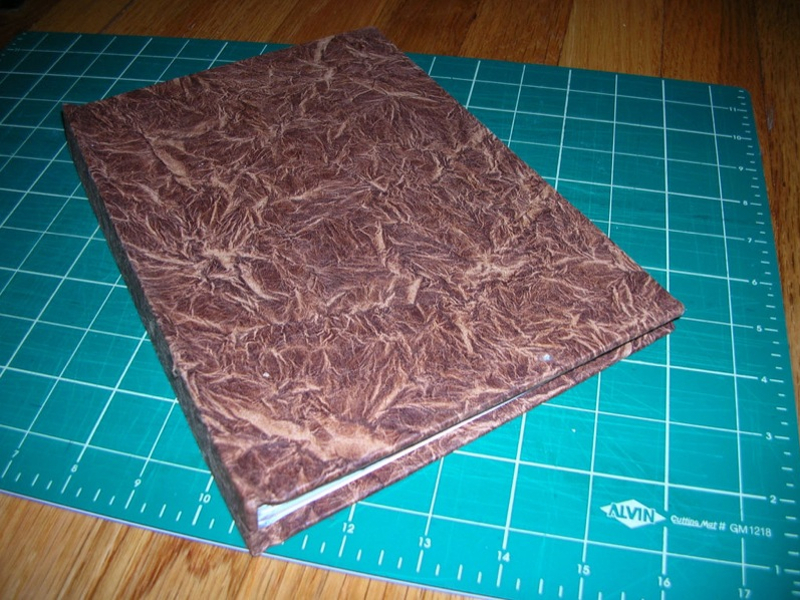

Lay the book open, and brush glue across the length of the head turnover. Stand the book up on its foot edge and roll the edges of the head turnover over the top of the board. Repeat for the foot edge. Brush fore edges with glue, fold the turnovers, and smooth out wrinkles.

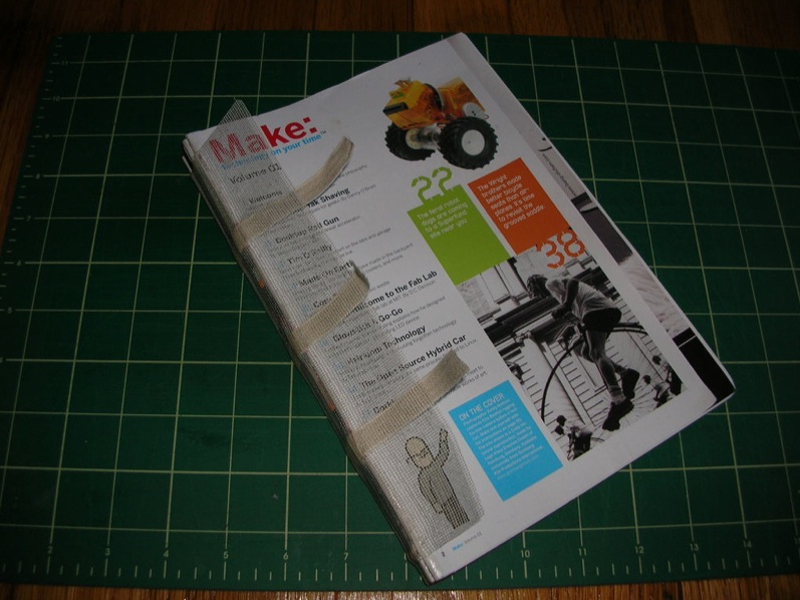

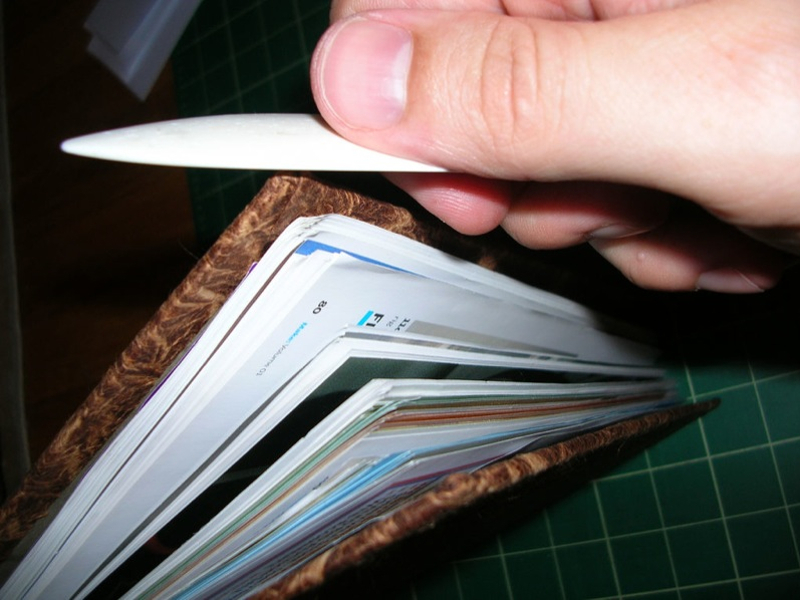

Lay sheets of wax paper between the cover boards and your block of signatures, and press under heavy weights overnight.