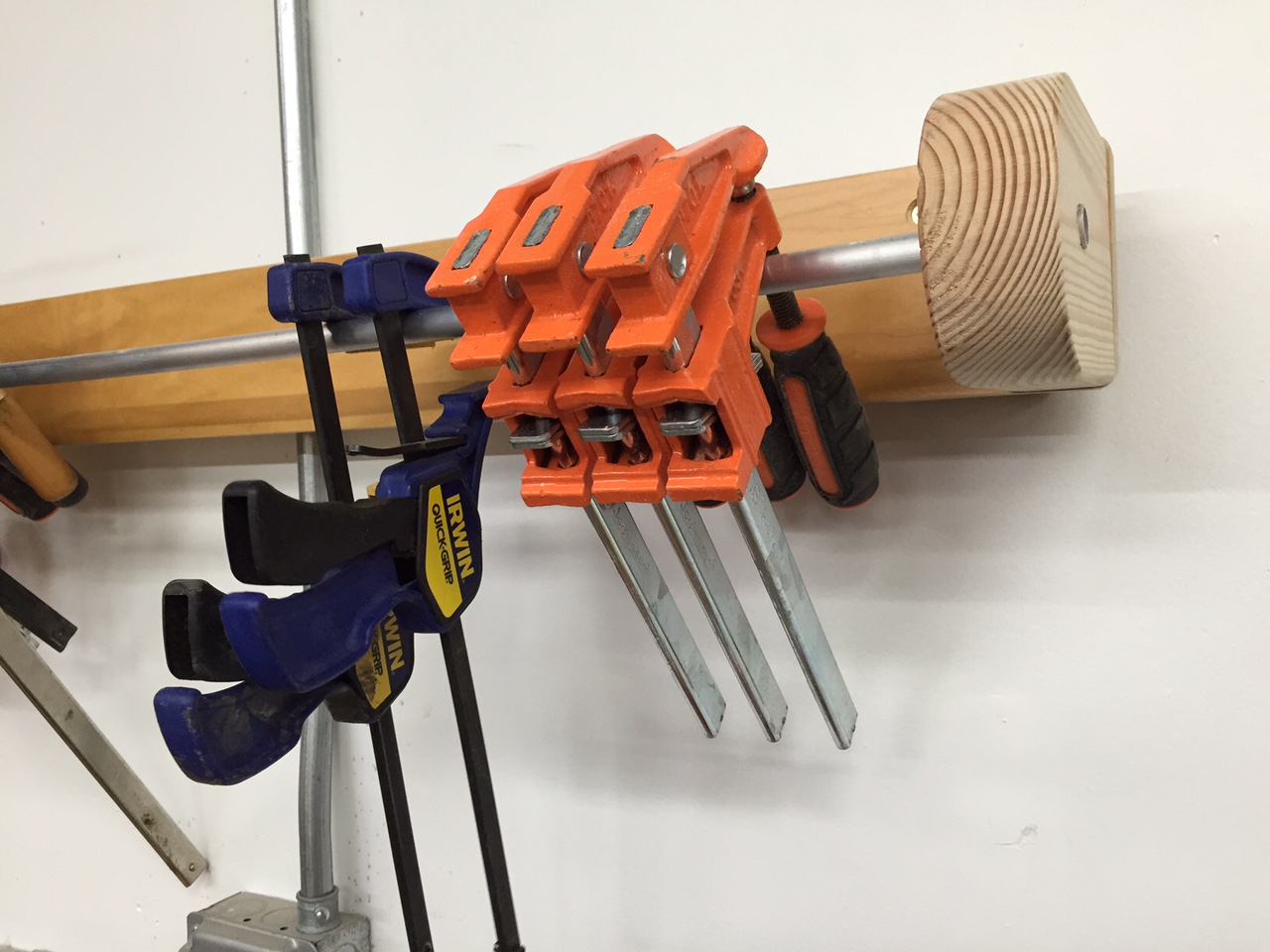

This simple clamp rack provides easy-access storage for a number of different clamp styles. It only takes about an hour or two to build, and uses common materials, making it a great project for those looking to organize their shop. Check out the photos to see how to hang C-clamps, bar clamps, and Quick-Grips.

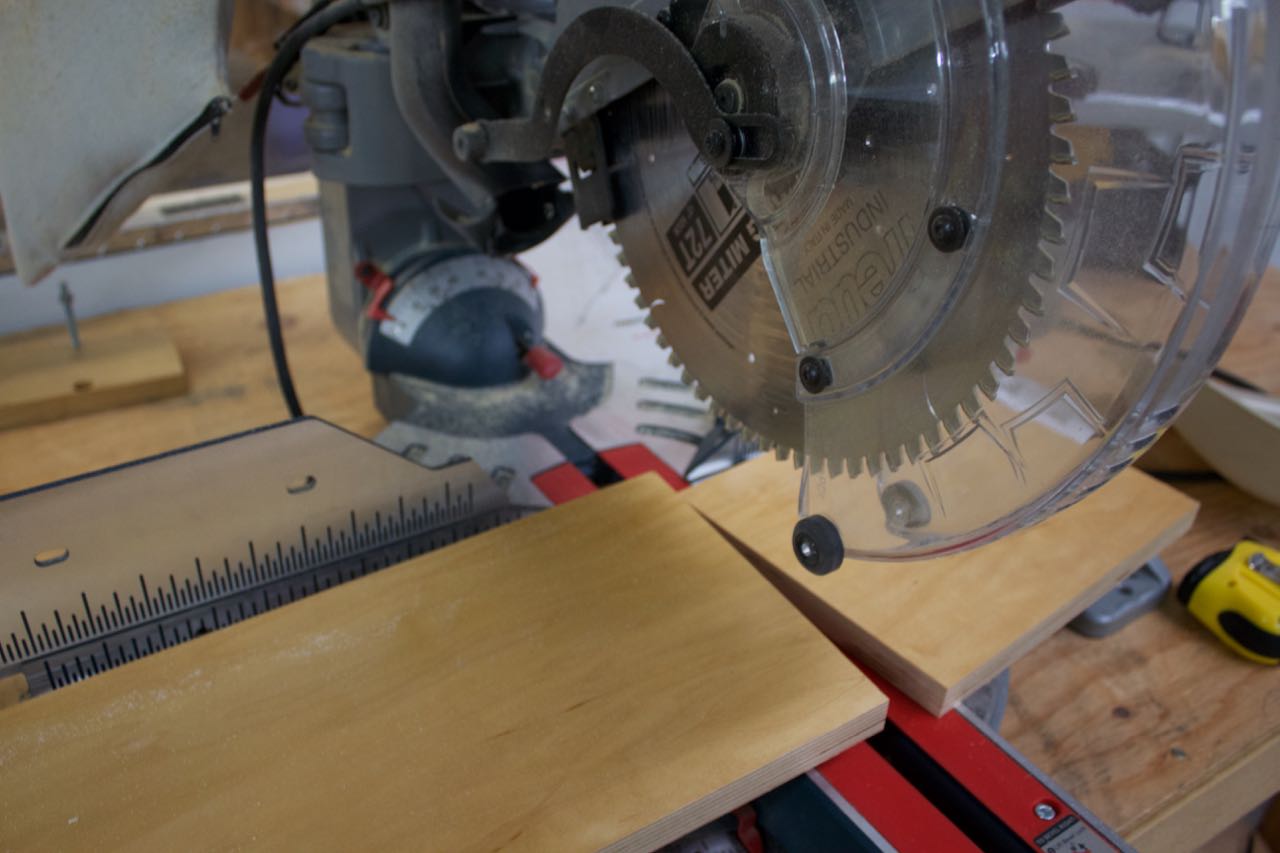

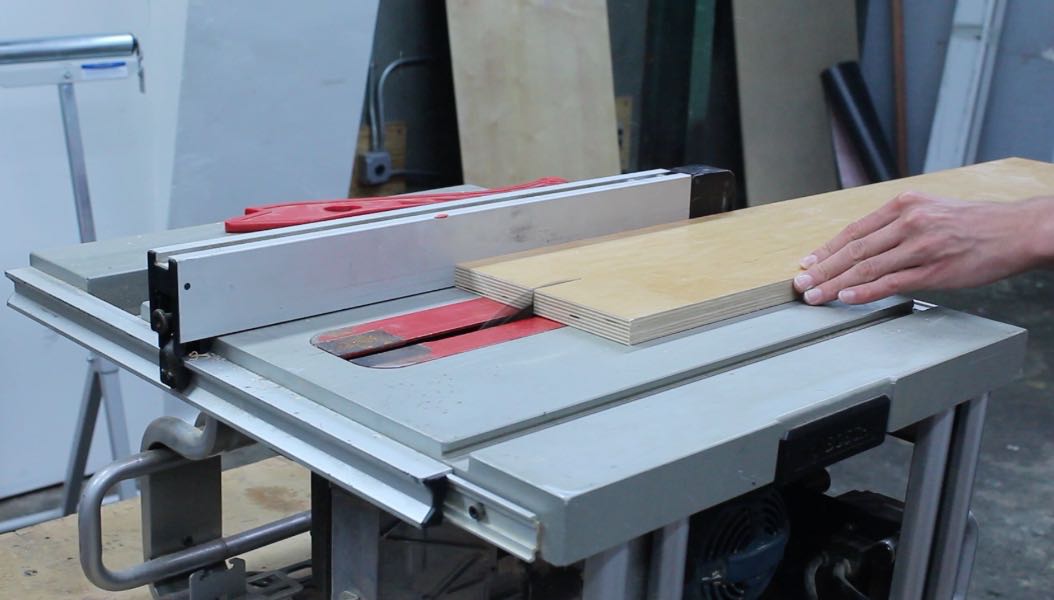

To make this project, check out the step-by-step instructions below. You’ll need some basic woodworking skills and a few common tools. If you don’t have these tools then head over to the closest makerspace.

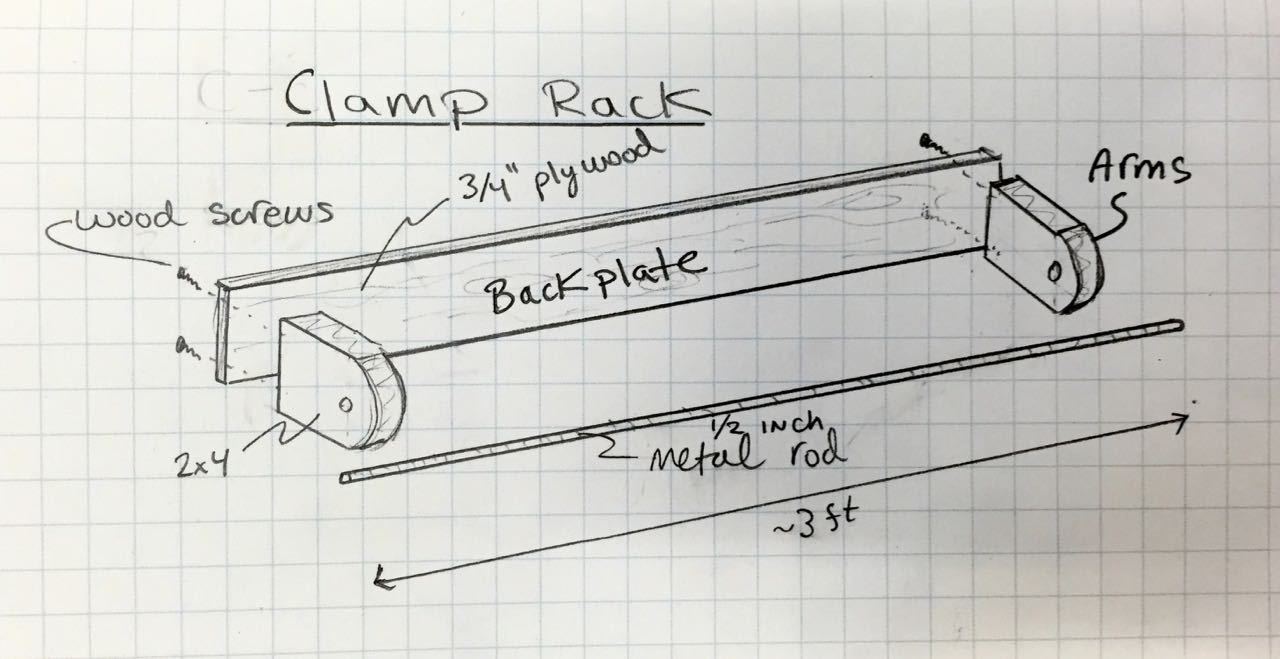

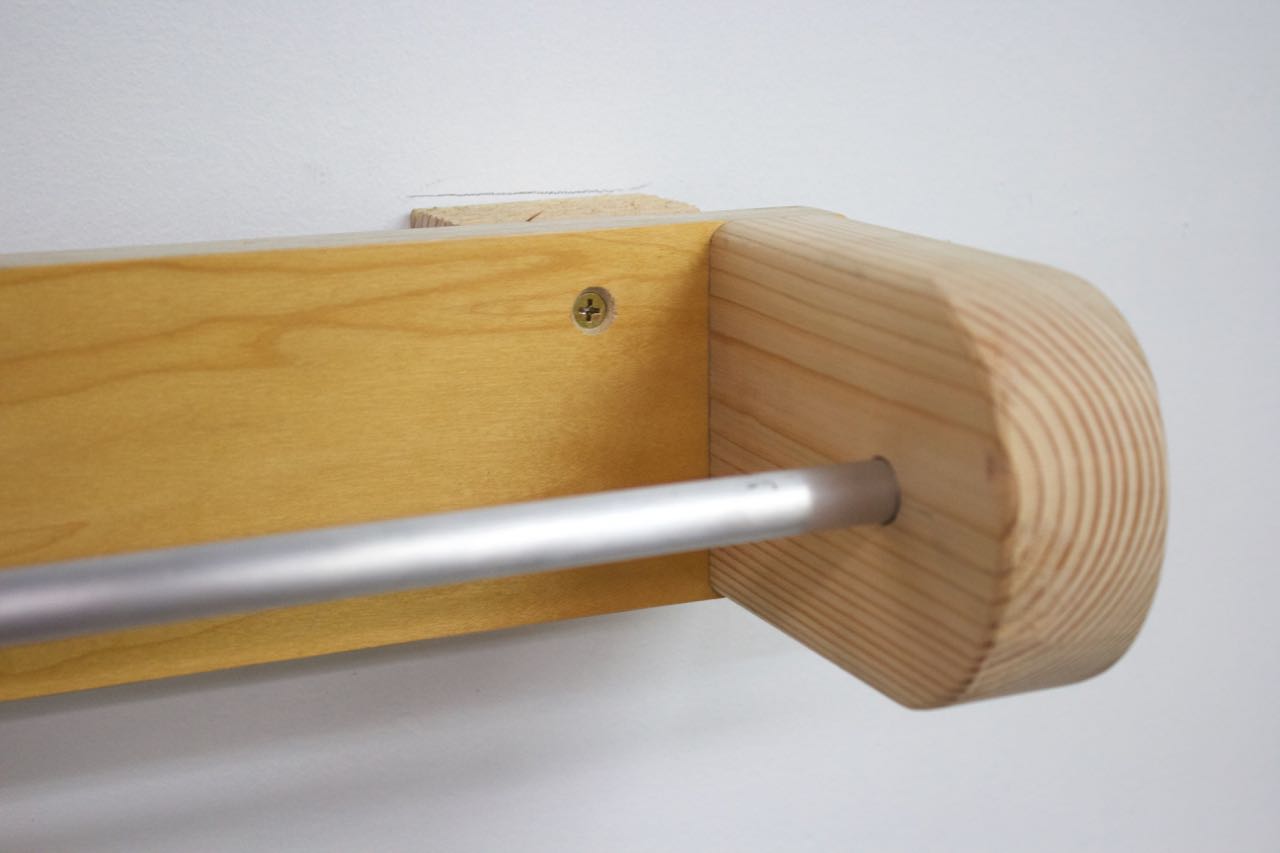

The rack design can be altered to accept different types of clamps and to accommodate whatever materials you have on hand. The backplate is shown as ¾” pre-finished maple plywood, but 2×4 lumber can be used instead. Additionally, the arms that hold the metal bar can be made from other types of wood or hardware, such as shelf-hanging brackets. The length of the rack can also be adjusted to fit your particular shop. In this project, you’re going to learn how to build a 3′ rack, which is a pretty good length for most walls and can hold 10–20 clamps, depending on the size. Before you build the rack, you should inventory your clamps to see how big a rack you will need, and factor in a bit of extra room in case you acquire more clamps in the future.

Over here at Maker Media Lab, we are still in the process of setting up our new shop, so we developed this project in an effort to organize and clean up our workspace. This post is part of a larger initiative to document our internal shop setup process, so look out for more posts about shop organization!