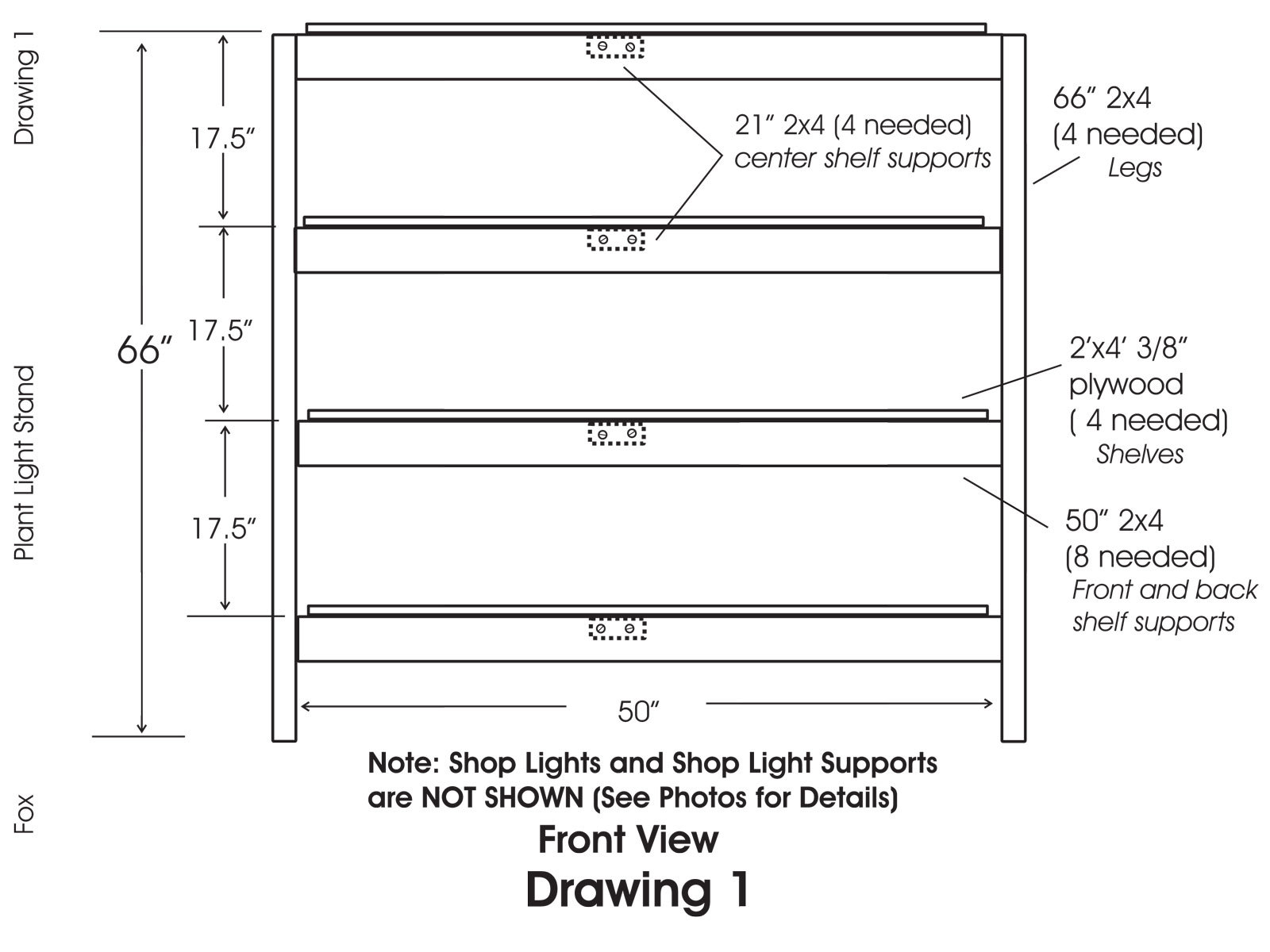

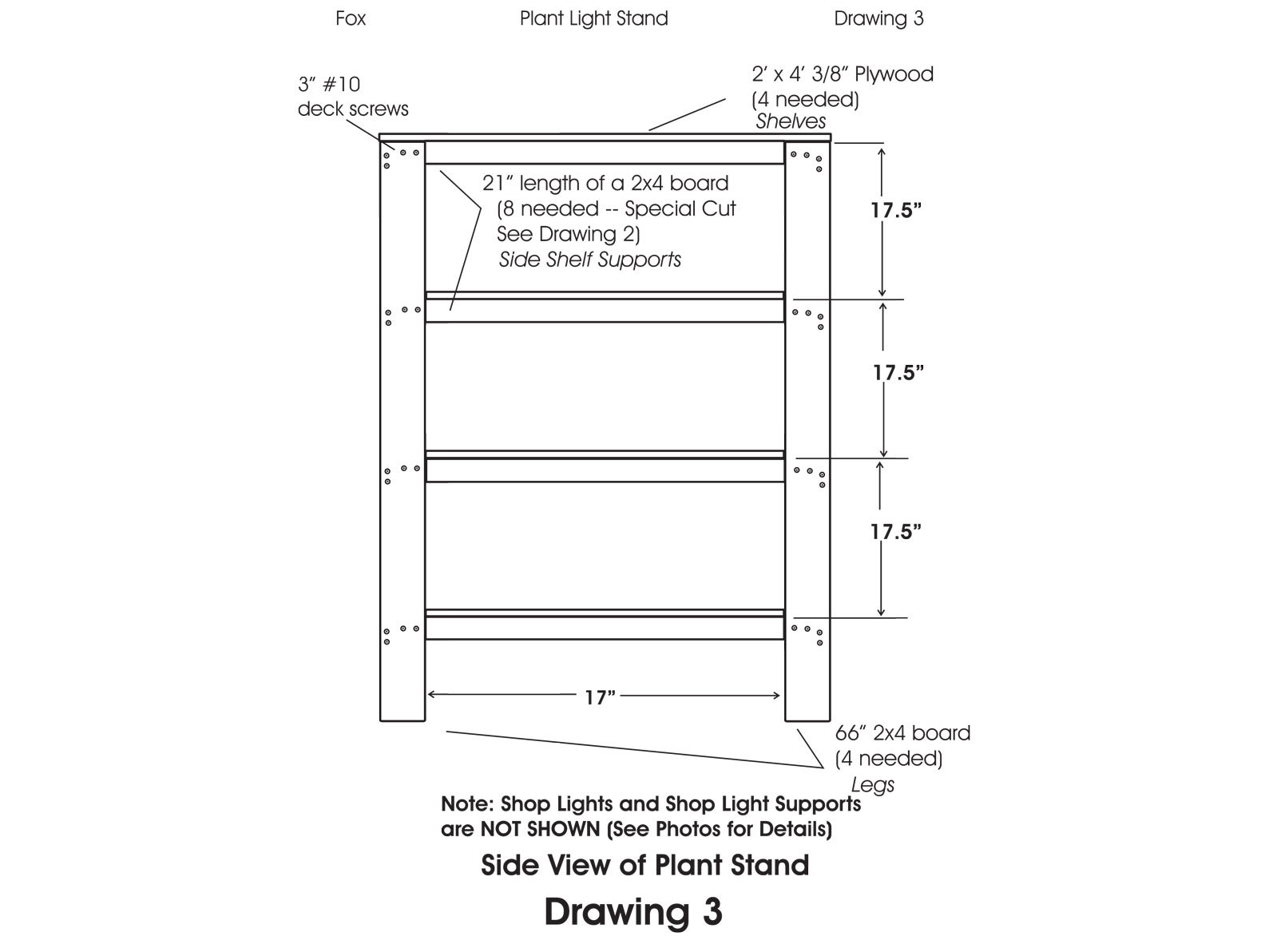

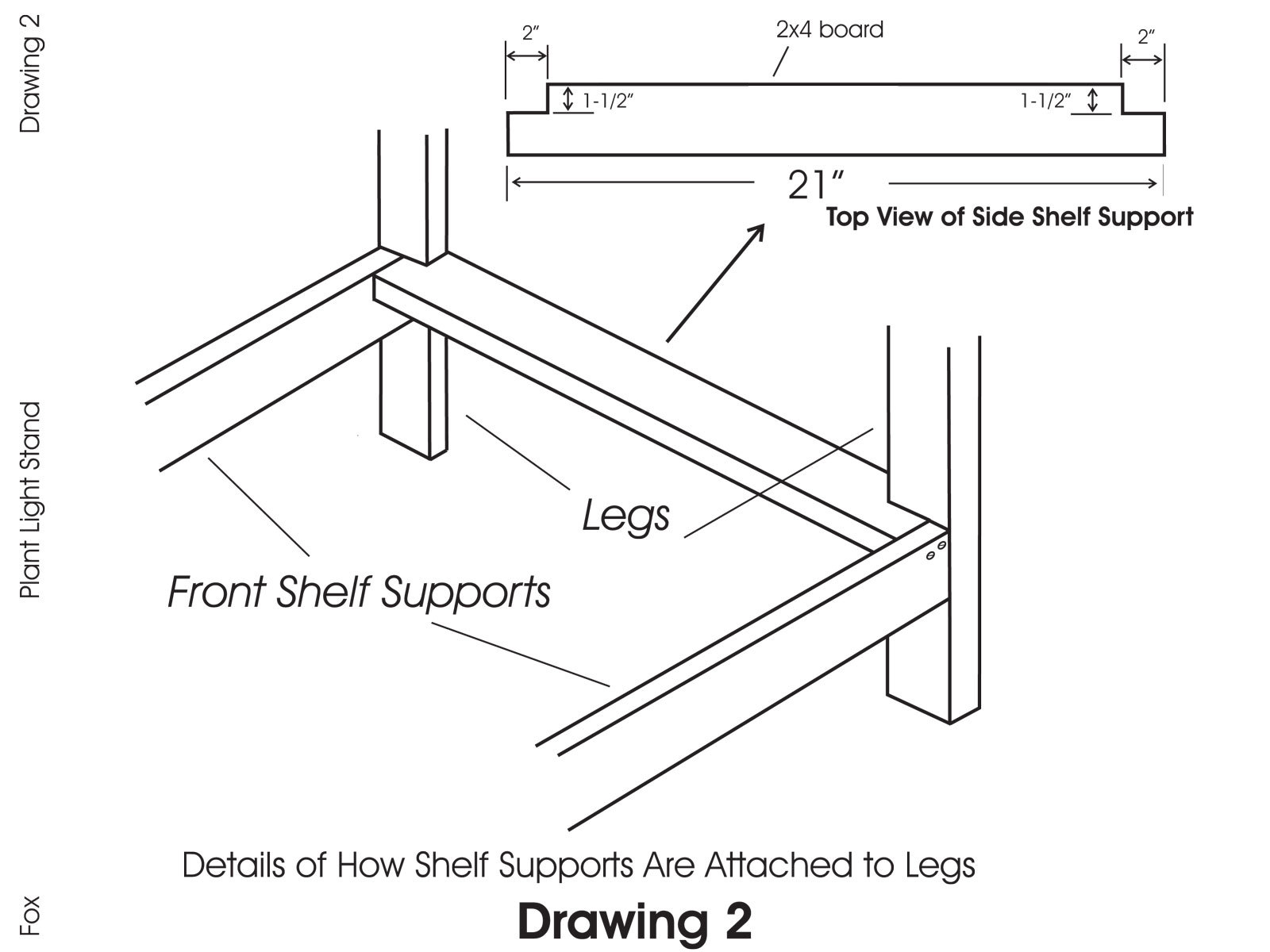

If you aren’t fortunate enough to have a heated greenhouse but still want to start your own plants from seed in the winter, this inexpensive plant light stand will get your plants growing — even in a dark, dungeon-like basement. It’s made primarily from common 2×4 boards, 3/8″ plywood, and fluorescent shop lights.

A neat feature of this stand is the adjustable height of the lights over the plants. You can easily raise the lights as the plants grow, which keeps the leaves from burning and gives the plants plenty of light for good, healthy growth.

This free-standing, 4-shelf plant light stand can hold as many as 8 shop lights and 16 standard-sized 10″×20″ plant flats. If you don’t need that much space for growing plants, you can start out with just 2 shop lights over one shelf and easily expand it in the future if you want to grow more. In the meantime, you can store your growing supplies on the unused shelves.