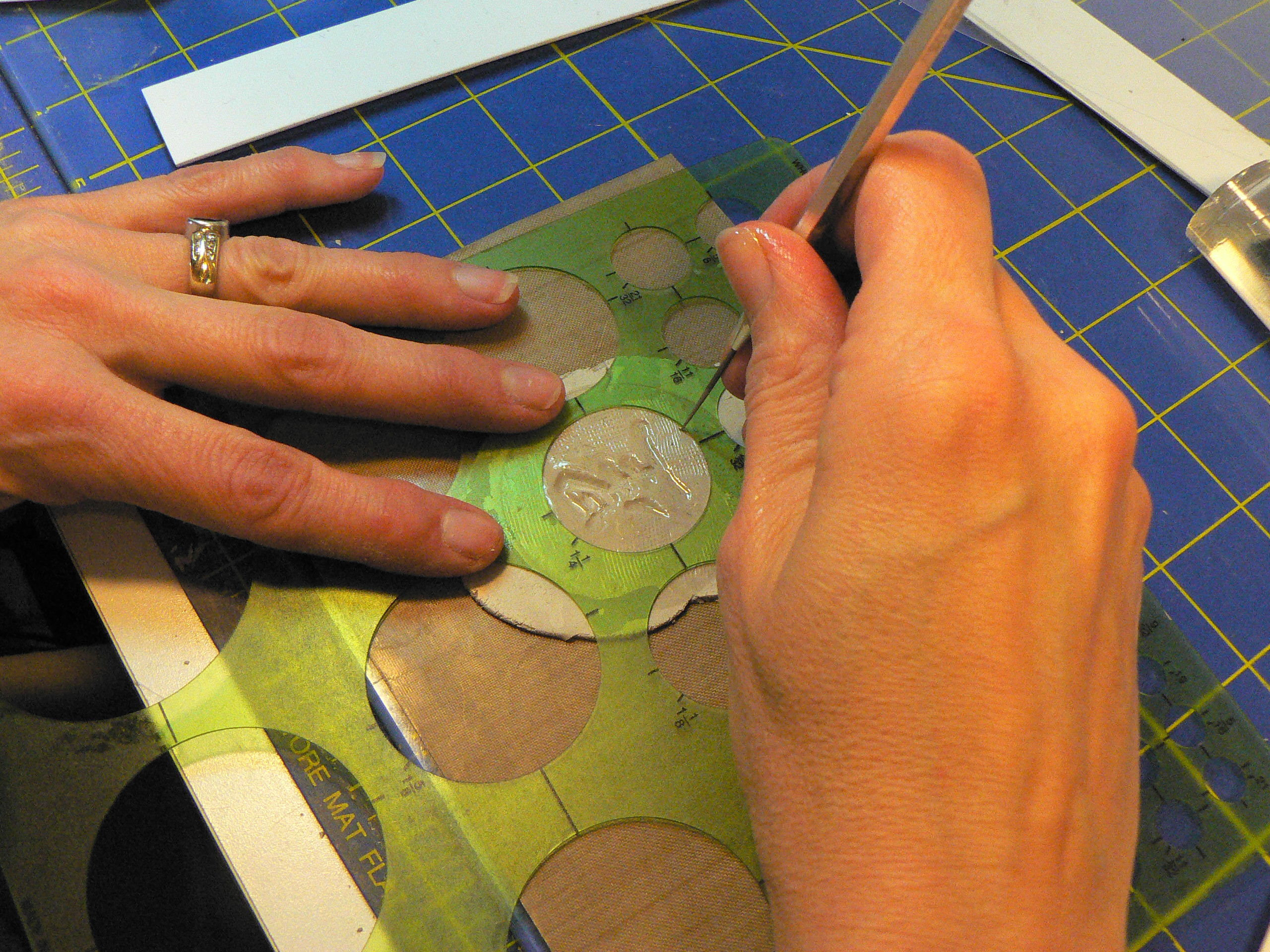

From the moment I first touched precious metal clay (PMC), I never looked at the world in the same way. Instead of seeing fruits and vegetables in the grocery store, I saw amazing textures that could find their way onto my artistic creations. Ancient textile designs became jewelry designs. The ability of this magic clay to hold detail is unsurpassed!

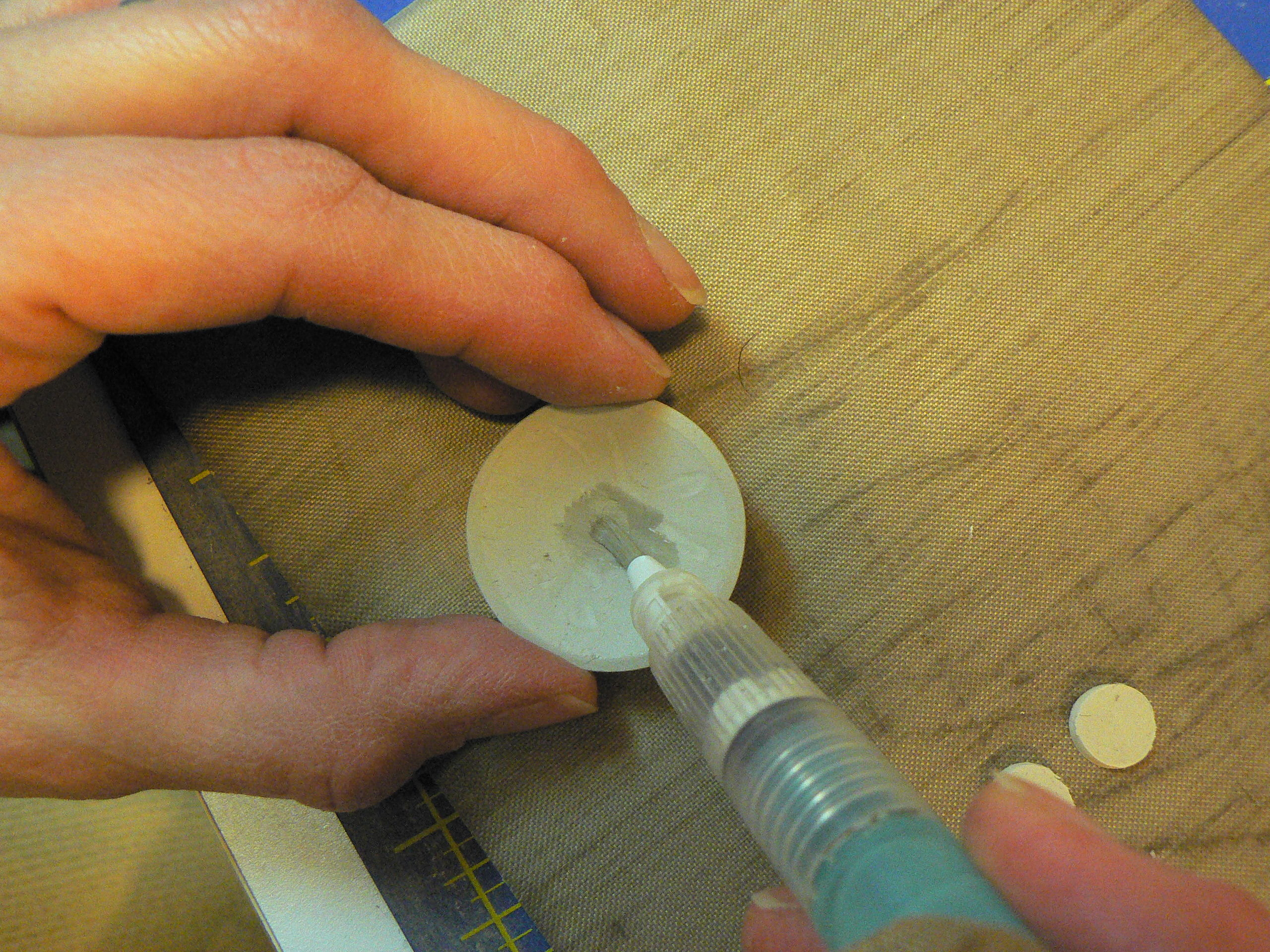

Mitsubishi Materials, Japanese manufacturer of highly refined gold for microchips, developed this amazing clay to answer the question “Can it be done?” Precious metal clay is made of fine metal particles suspended in an organic binder that burns away when fired, leaving just the precious metal. This is a new kind of alchemy, and it comes in 22-karat gold and fine silver, in lump, paper, and paste forms. The possibilities are endless!