The primary arms attach the cylinder/frame assembly to the secondary arms, which support it. They also attach to the Brickholder plate, the Dirt-keeper plate, the Controller Mount, and the Valve Mount.

Projects from Make: Magazine

Primary Arms

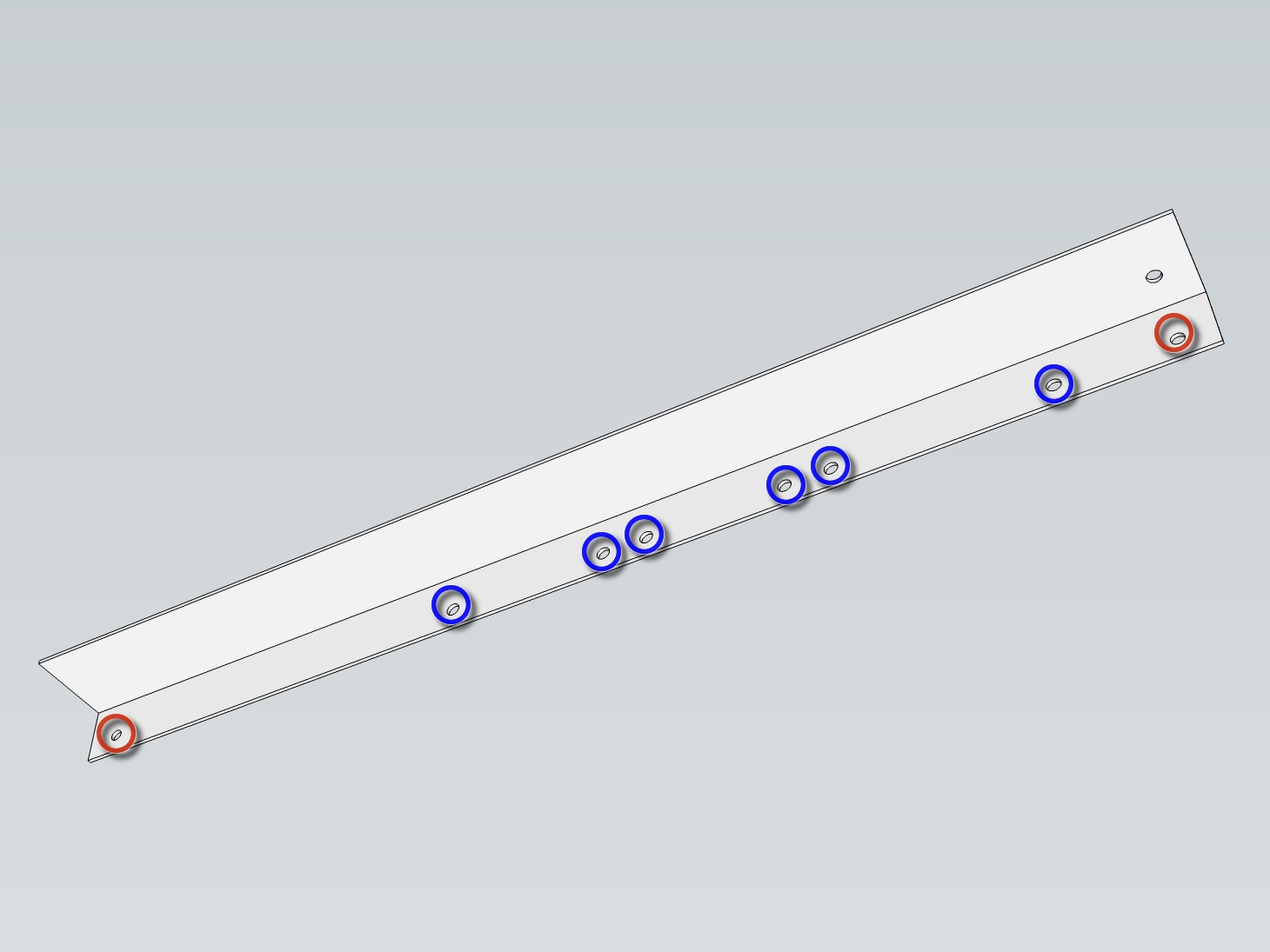

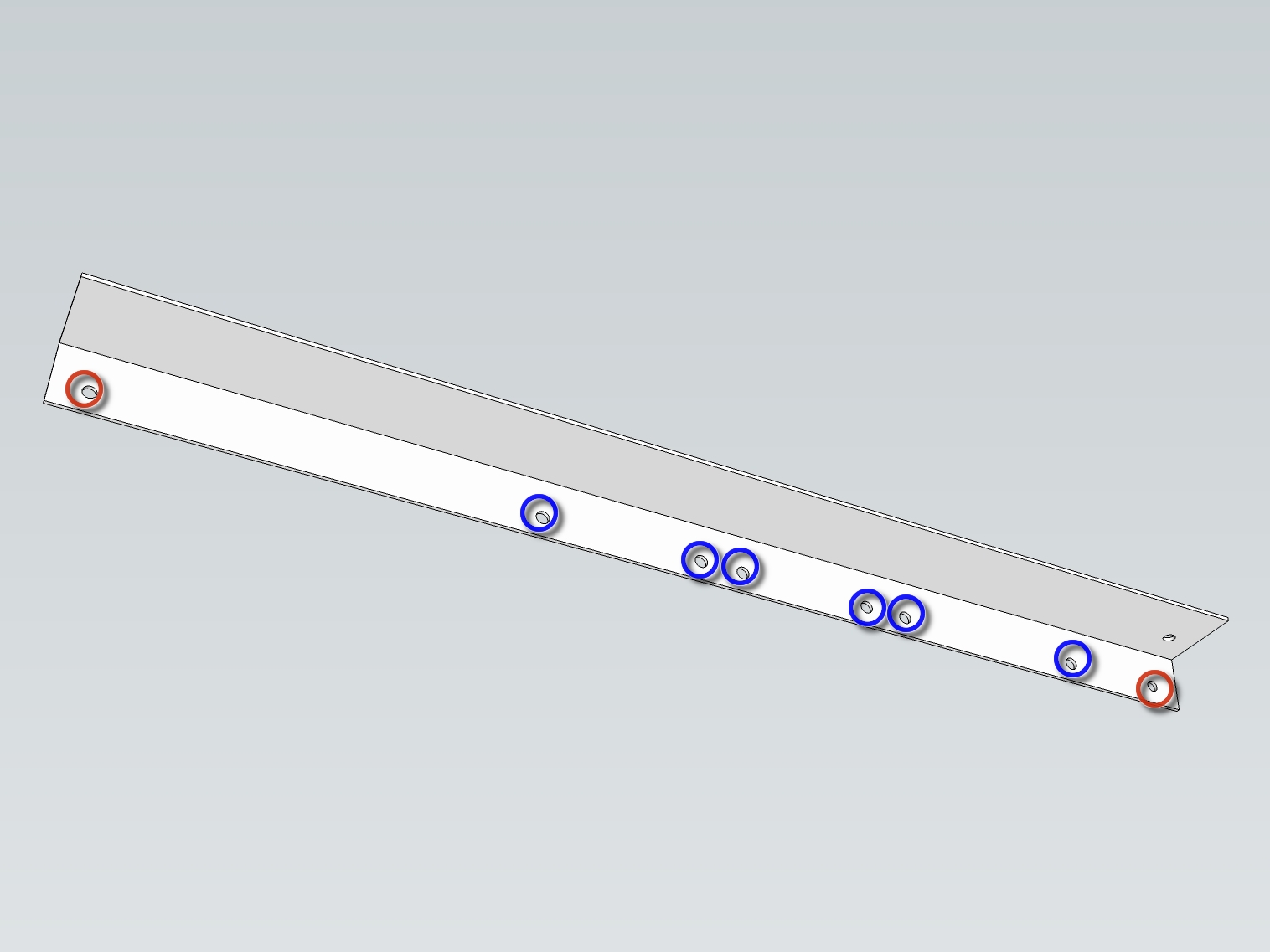

Assembling the Primary Arms: the main component for connecting the center column of the CEB Press to its support system.

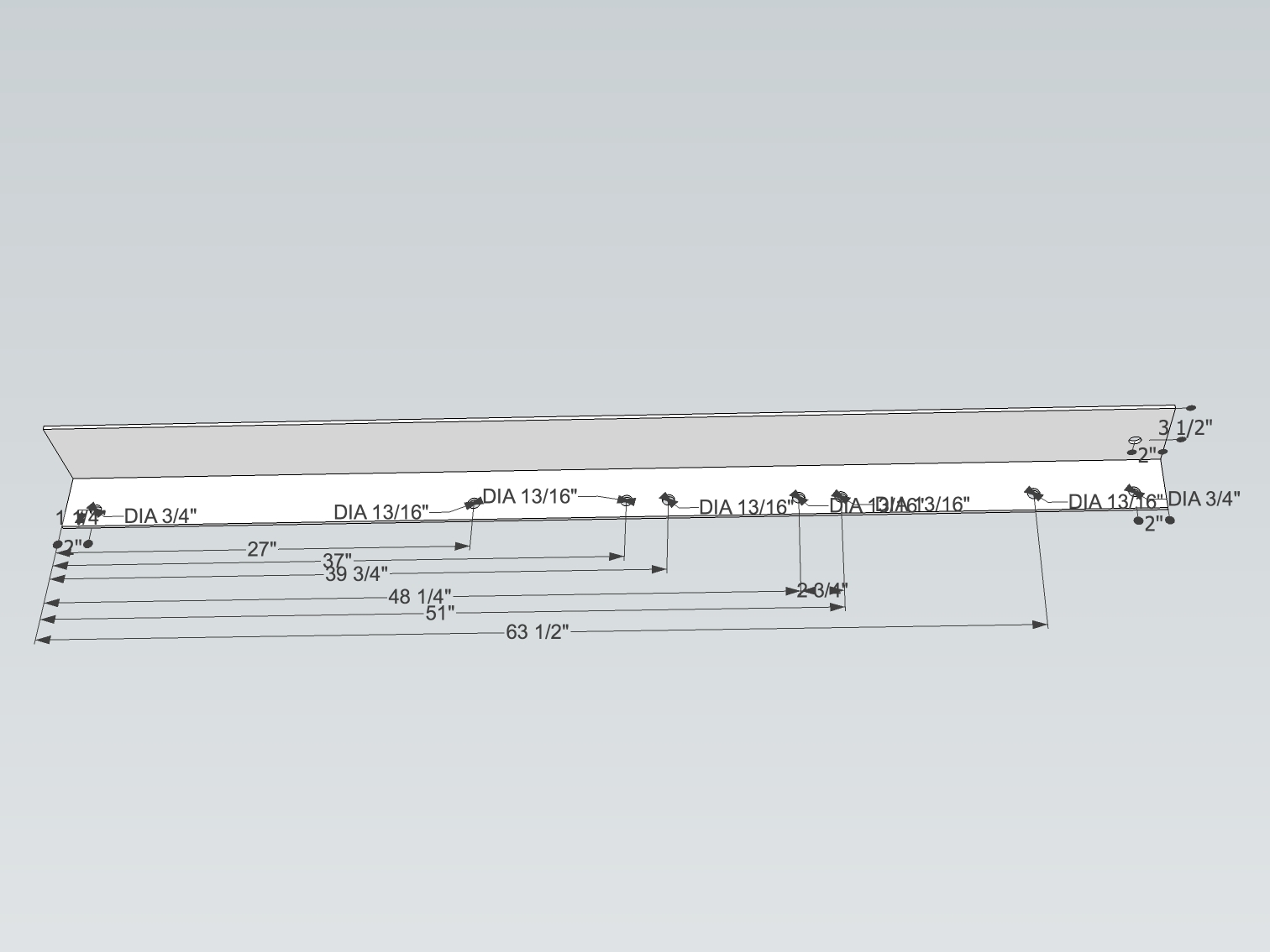

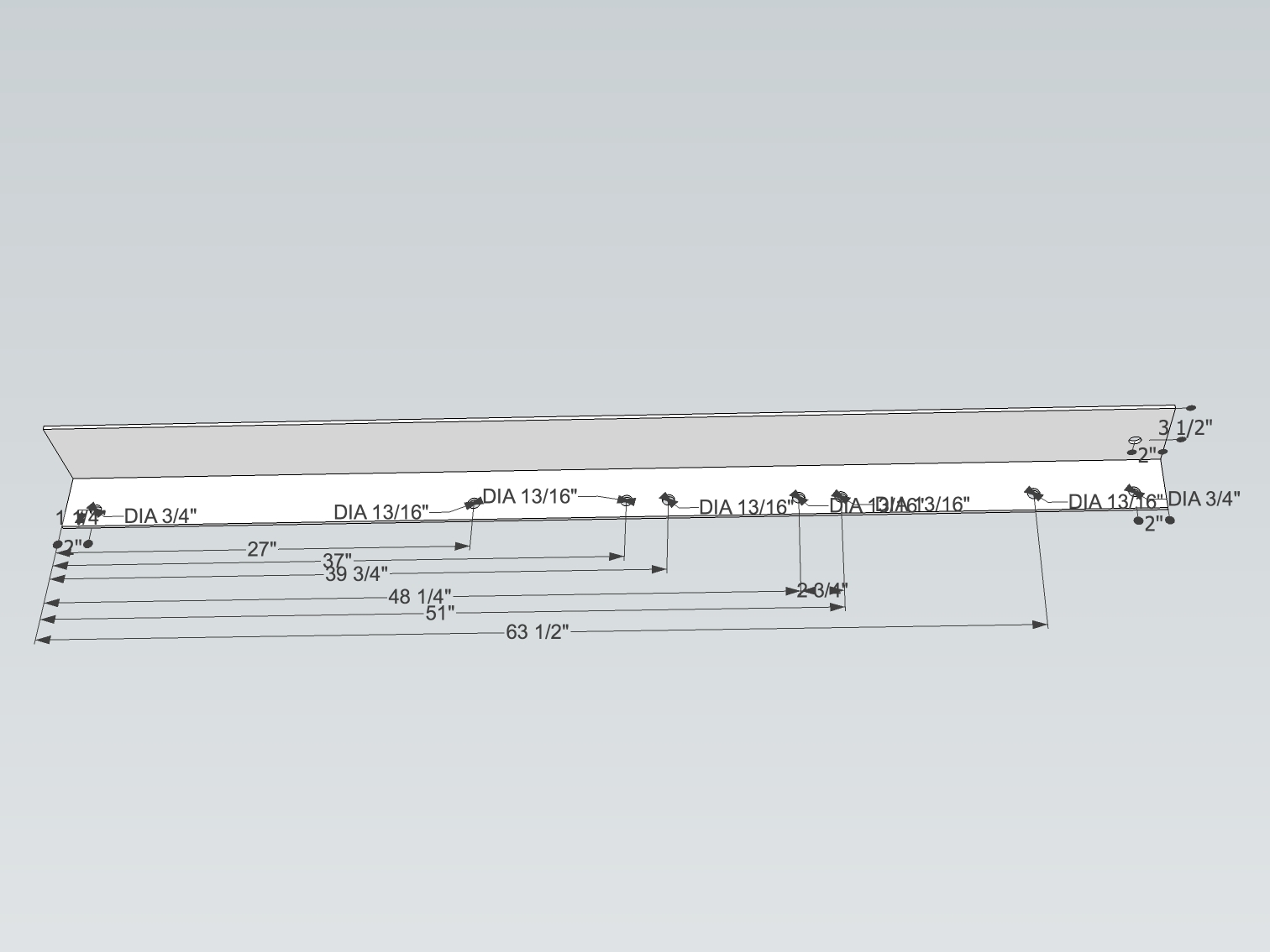

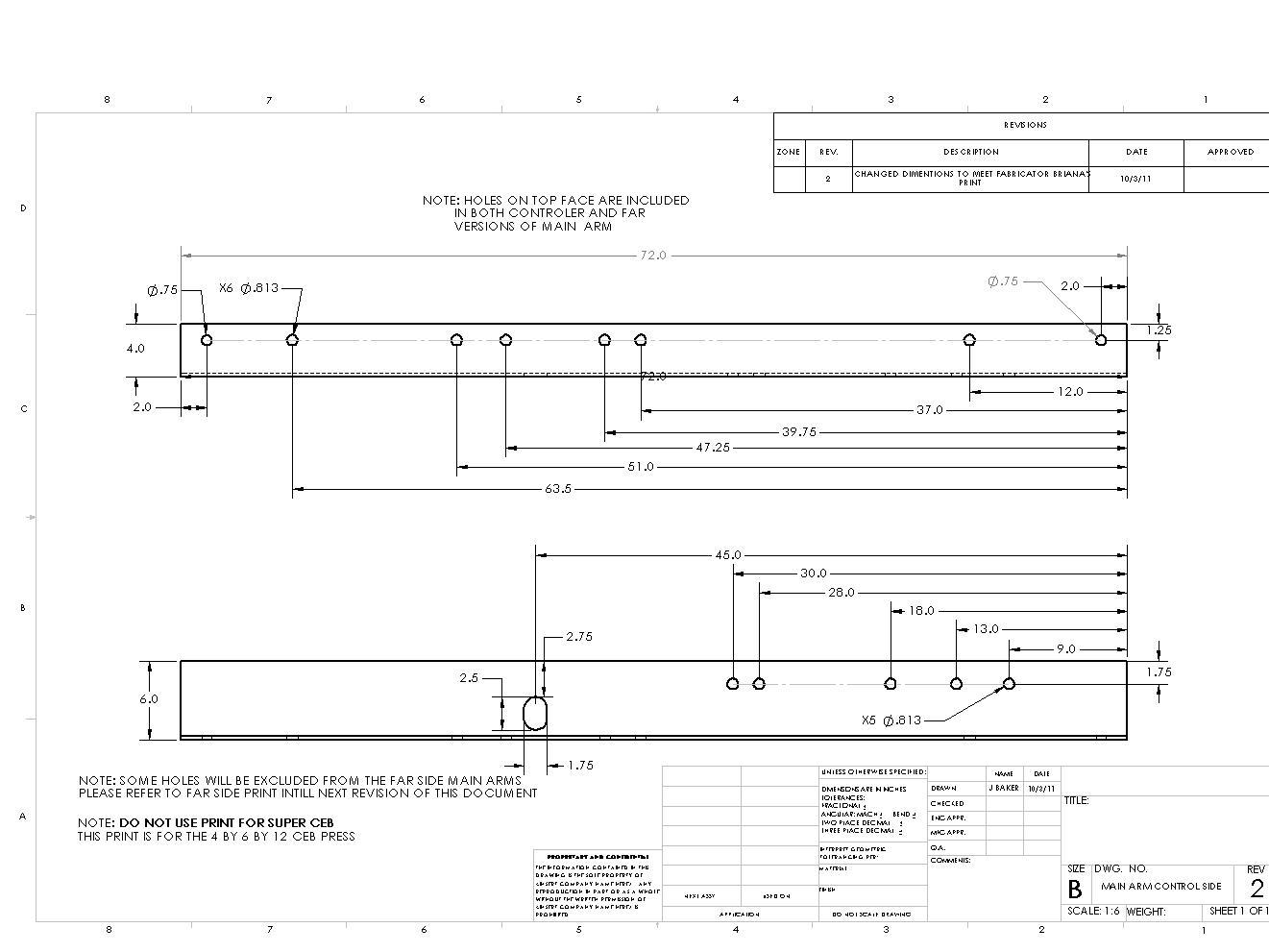

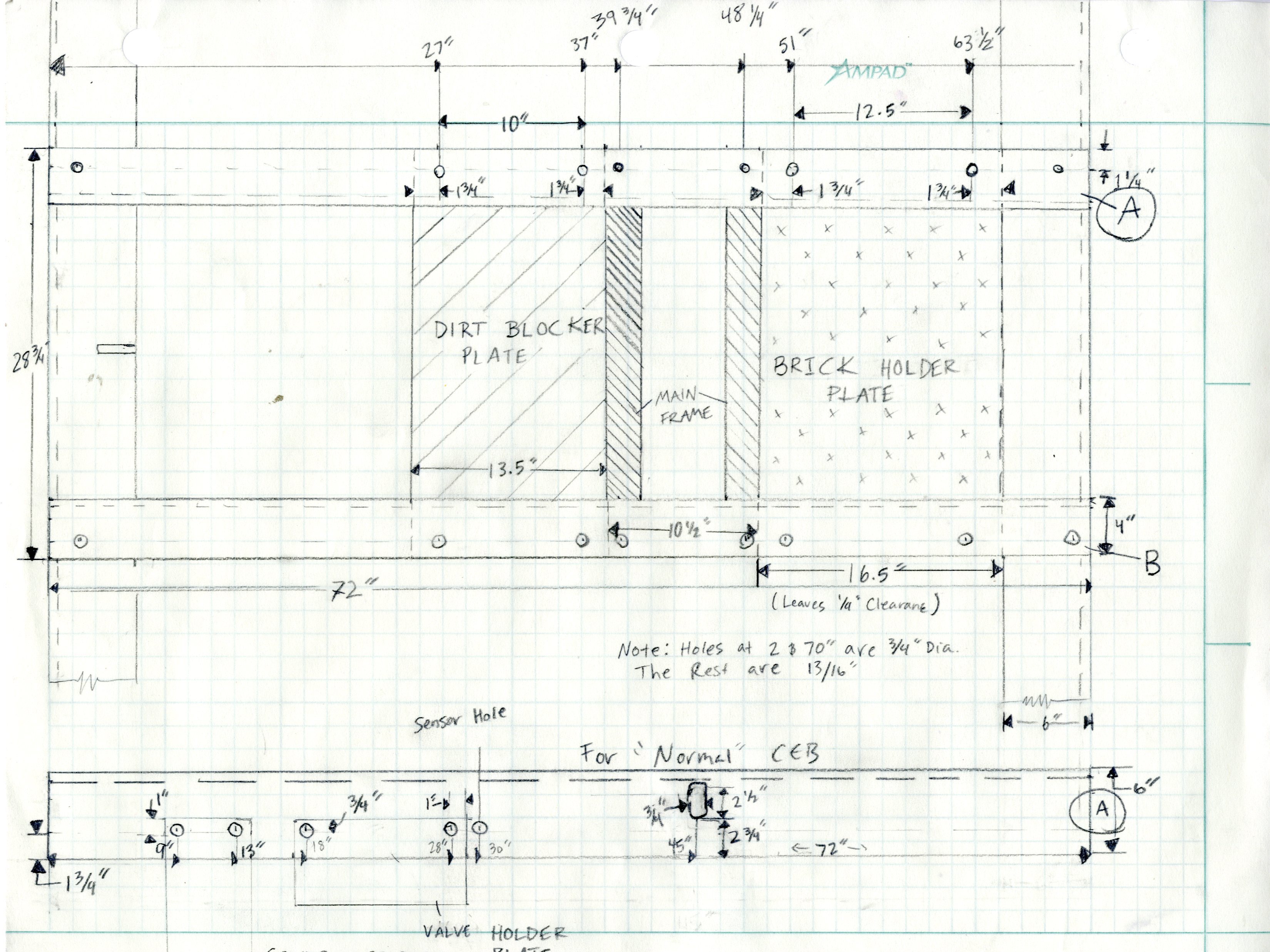

On one piece, mark holes on the 4″ side, all 1.25″ away from the edge for:

Two total 3/4” diameter holes at 2” and 70.”

Six total 13/16” diameter holes at 27″, 37″, 39 3/4″, 48 1/4″, 51″, and 63 1/2″.

Use this piece to mark the locations on the other side. They are to be mirrored, so make sure they aren’t in the same exact orientation.

Punch the Holes

Determine which one is arm A and which is arm B by looking at the diagrams. Label them.

On arm A, punch the following holes on the 6” side of the angle iron, measured from the left, each centered 1 3/4” from the long edge: Also, torch the hole for adjusting the rollers at 45″. Its shape is shown in the diagrams.

Five total 13/16” diameter holes at 9”, 13”, 18”, 28”, and 30″ inches.

Torch the roller adjustor hole in arm B, 45″ from the right, so the holes will be at the same frame location.