Halloween is a big deal at our house and every year it gets bigger! For better than a decade, we’ve been the scariest, noisiest, and spookiest house in town. Over the years, our haunt has evolved from a few pneumatic-powered zombie props on the front lawn to ghostly AV displays and multiple rolling, radio-controlled animated props trolling for victims up and down the street.

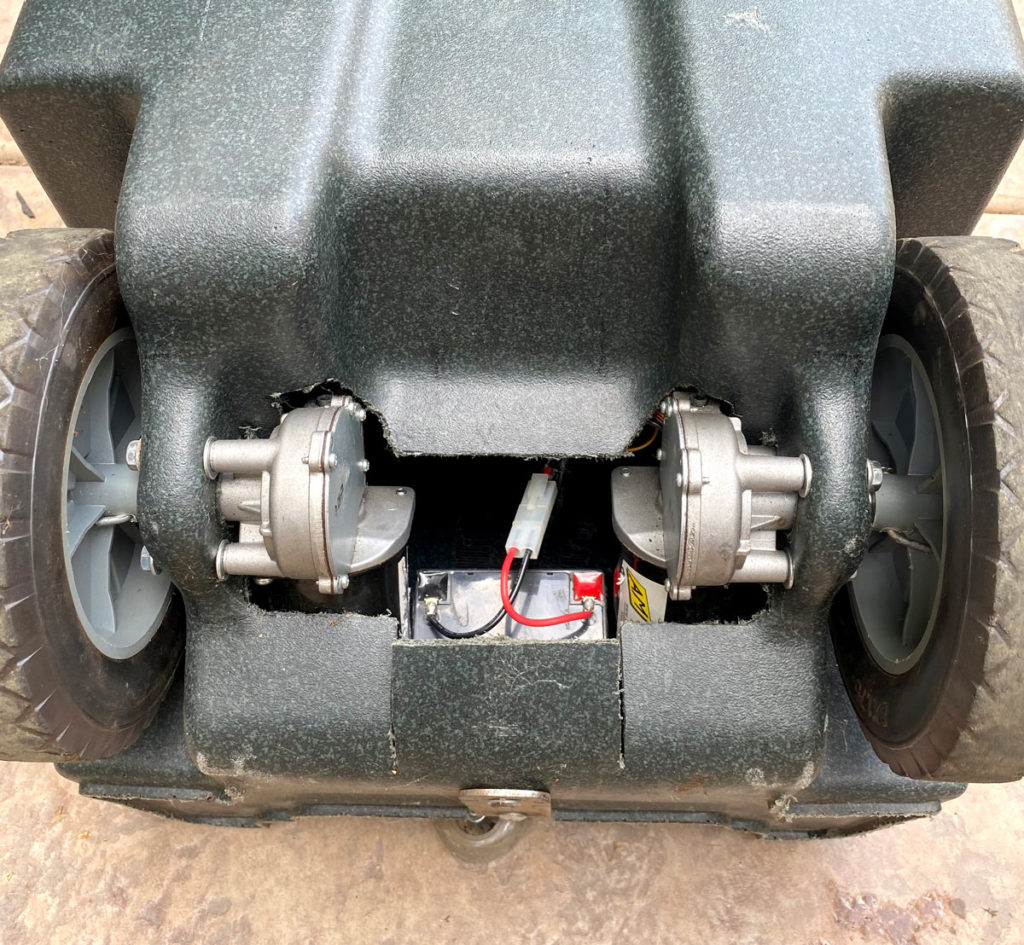

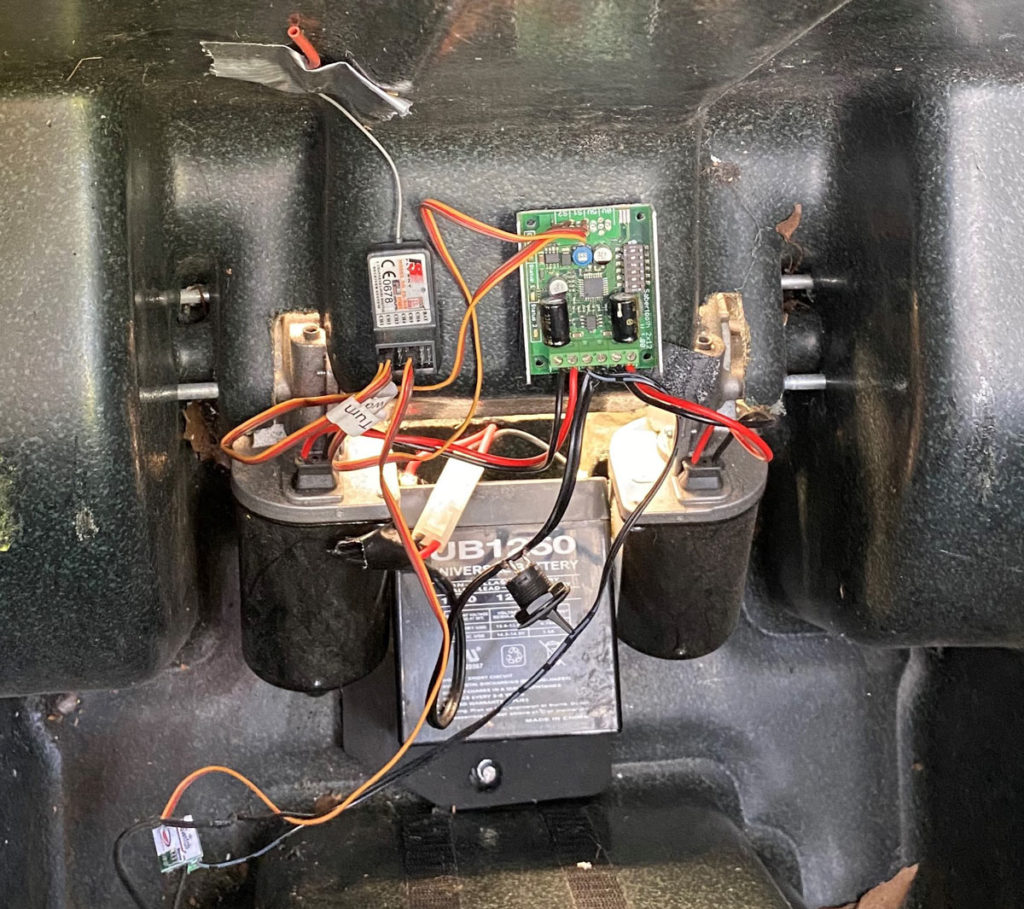

One of our all-time favorites is a mechanized device we affectionately call Oscar — a radio controlled, roving flip-top garbage can with a zombie prop that pops out with startling speed on command. It’s powered by a small 12V sealed lead acid battery providing juice for the wheel motors, with a compressed air tank providing for the rapid deployment of Oscar the zombie when unsuspecting trick-or-treaters are nearby.

We often park Oscar next to the sidewalk alongside some real garbage cans and let the fun begin. Alternatively, we slowly roll up behind unsuspecting kids and their parents and let Oscar pop as they turn around. Either way, there’s plenty of dropped candy at the end of the night. We were fortunate to share Oscar and our other props with our local maker community at the 2018 Maker Faire Bay Area and it was nonstop fun all three days.

Oscar’s “screaming success” comes from its ability to easily move from place to place, its initial benign appearance, and its very quick compressed air mechanism. It’s a higher-tech update of the classic “Trash Can Trauma” prop, and a worthwhile build if you’re looking for the ultimate Halloween prop this year.

Scary Driver

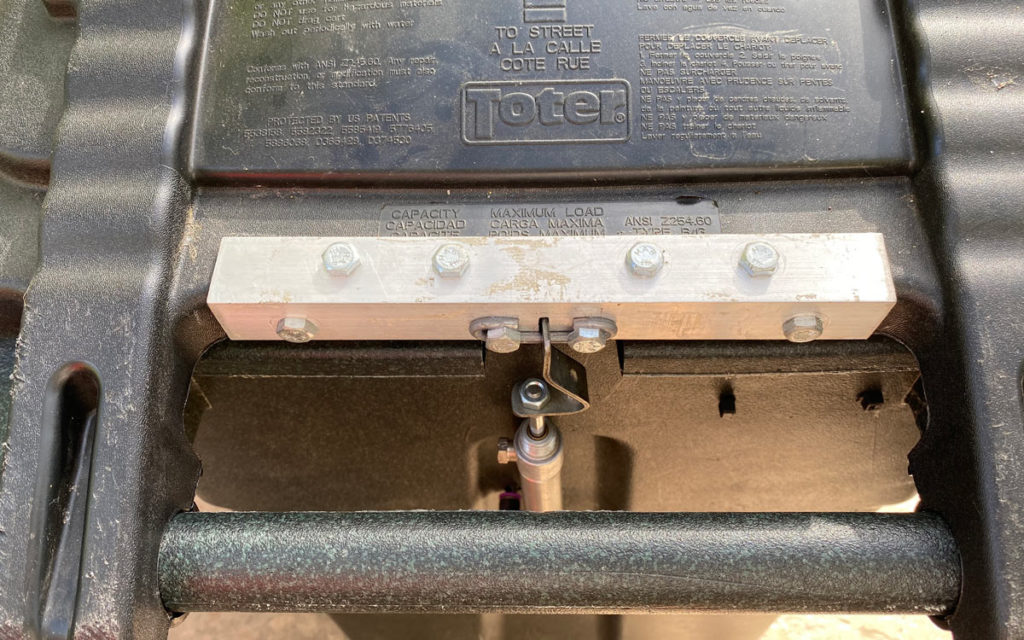

Oscar is made up of an electrical component that uses a 12V battery to power two electric motors for mobility of the garbage can, and a mechanical component that uses compressed air to power two air cylinders. One cylinder opens the garbage can’s lid and the other deploys the zombie or scare prop of your choice.

Both electrical and mechanical components are remote controlled via a hobby R/C transmitter and receiver. The motors are driven via a dual motor driver board which plugs into the R/C receiver. The compressed air is released in short bursts via a 12V solenoid air valve to activate the zombie and lid. This valve is controlled by a relay switch, which also plugs into the R/C receiver.

Although I refer to specific materials and methods, please use this tutorial only as a guideline. You may already have some of the necessary materials lying around in the garage, or you may have specialized skills like 3D printing, machining, and welding; adjust your build accordingly. The most expensive components are the motors which can set you back about $120 each if bought new. However, less expensive windshield wiper or car seat motors would work as long as they spin about 100rpm and their shafts are at least 2½” long to allow for wheel mounting. Of course, motor and wheel mounting will vary.