This project originated years ago in Portland, Oregon, when my architect son Mike handed me a cup of locally roasted coffee, saying, “Here, Dad, you’ll like this.”

Up to that day I’d never drunk an entire cup of coffee. I even survived my stint in the Navy without coffee (barely). So naturally I was shocked that Mike would even offer me a cup, but I took it out of politeness, mostly.

Guess what? It was delicious. Times change, tastes change, coffee’s very different from place to place. Who knows what caused me to suddenly enjoy coffee? Oh, yeah: cream and sugar.

On my trip back to North Carolina, I determined that great coffee = fresh coffee, duh, and a big step toward achieving that would be to roast my own. I even considered growing the beans. (Don’t laugh — check it out.)

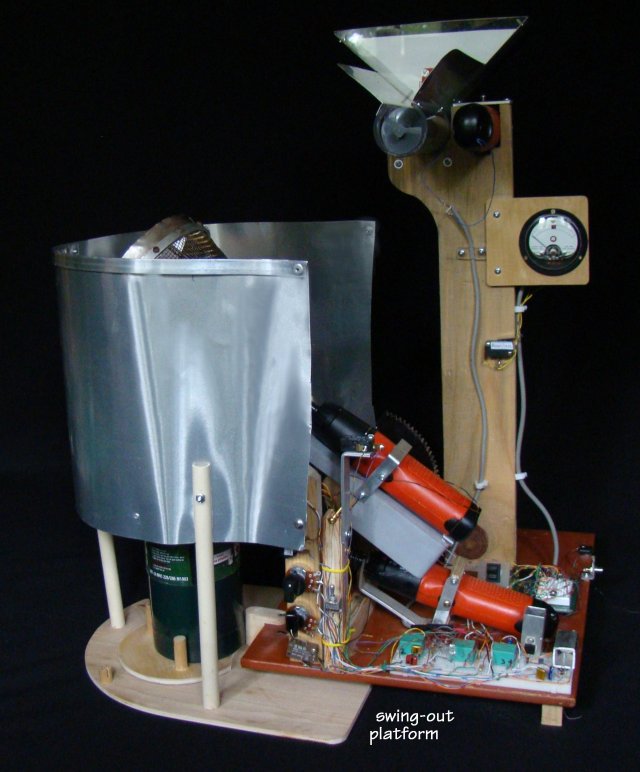

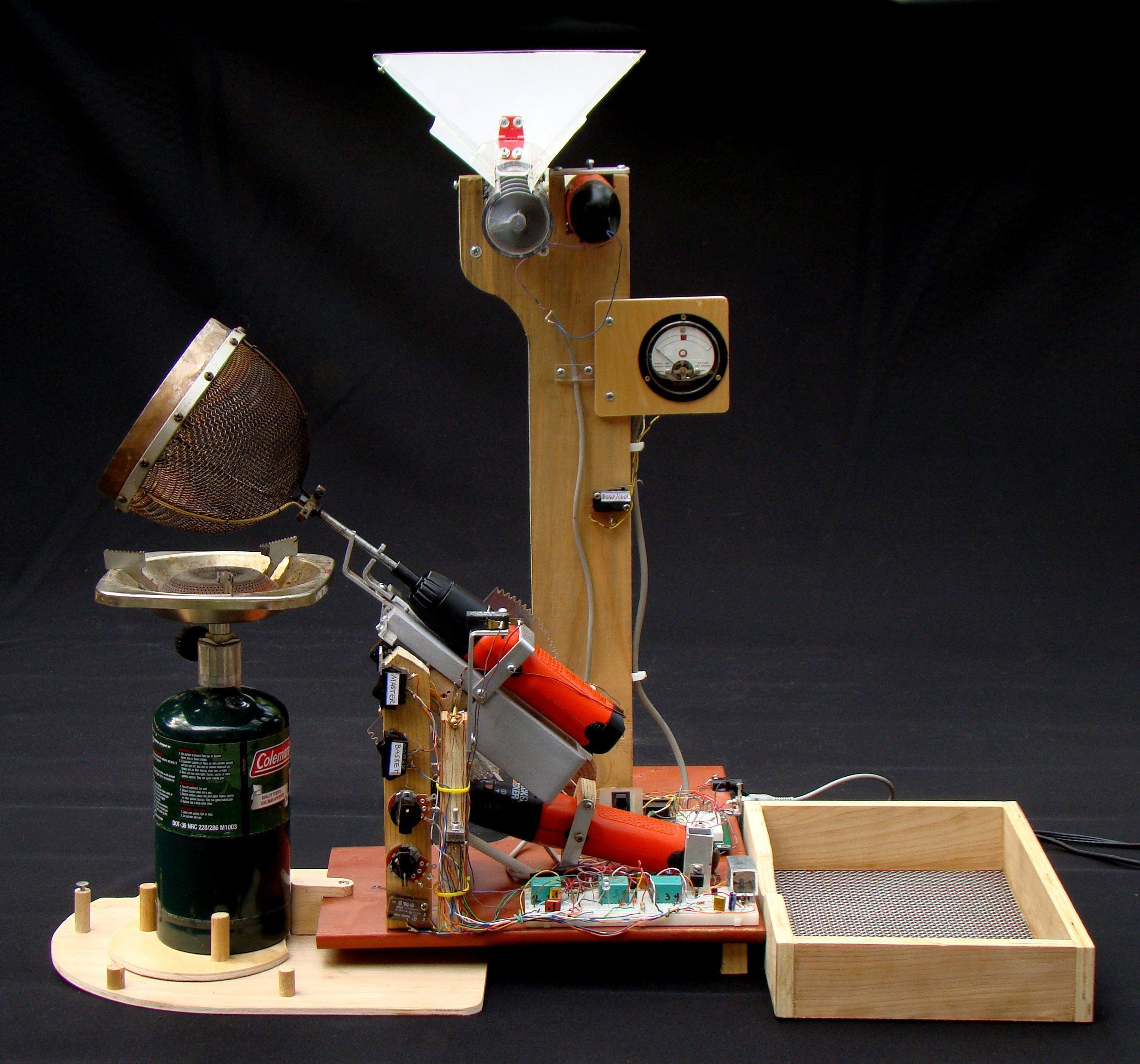

Anyway, after much sophisticated research (Googling home roasting coffee) and many mostly unsuccessful attempts, a decent small-batch roaster finally emerged. It eventually found its way into Volume 08 of Make: magazine, as the Nirvana Machine, an easy-to-build, easy-to-use home roaster. It had — still has — two big advantages over others in the market: it’s easy to see the beans while they’re roasting and it’s portable. I’ve used it for years without modification.

However, there was always this lingering, increasingly urgent desire to improve it. The roaster requires considerable intervention between consecutive batches: stopping the roasting by turning off the heat, dumping the beans, cooling the beans, then re-loading the basket and setting the temperature again on its little propane camp stove.

Refining the Goal

Over the last few months, I refined a new goal: come up with a cheap, easy-to-make, set-and-forget continuous coffee roaster. So I did. Several, many, and they all failed in one way or the other — some quite spectacularly (mostly the “forget” part).

Ideally, continuous coffee roasters expose every surface of every bean, of a given variety, to consistent (though controllable) heat and time cycles. Professional roasters come very close to doing this; I never did (if you know how do this, email me). At this point I could have decided that this would be a big-time fail, throw out those black beans, cut my losses, and moved on.

To what? Another completely different project or a souped-up variant of the Nirvana Machine? Here’s my compromise: a hybrid which can continuously roast small batches, rechristened “A Coffee Mess.”

Roasting on the new machine still demands attention, but that’s not a bad thing. Coffee varieties roast with varying temperature and time profiles, so it’s prudent to keep an eye on the beans while they’re roasting.

Though, the rest of the process — dumping, re-loading and re-starting the roast — is now automatic: just touch a switch when the beans are roasted and a microprocessor takes over.

The other basket positions were pretty obvious: horizontal for dumping the beans and vertical for loading them. The easiest way to do this was to move the basket through an arc. The arc starts at the roasting position (45

The other basket positions were pretty obvious: horizontal for dumping the beans and vertical for loading them. The easiest way to do this was to move the basket through an arc. The arc starts at the roasting position (45