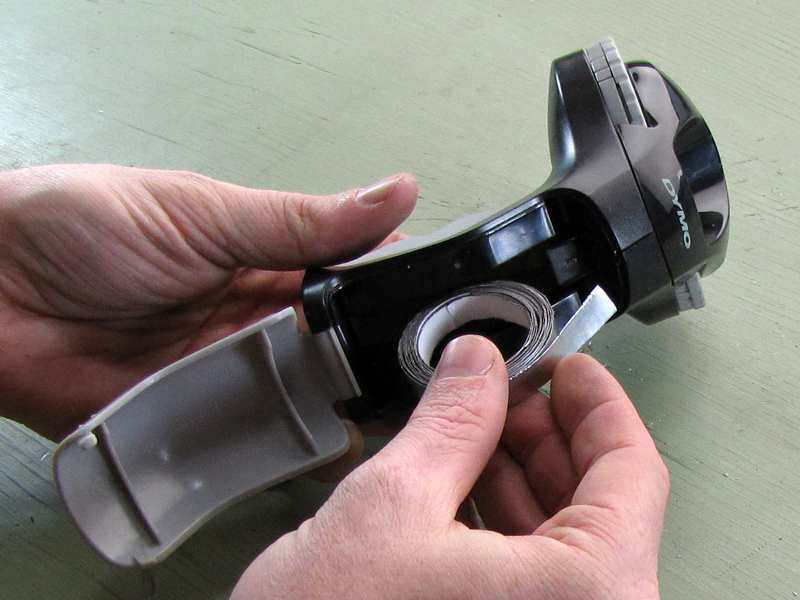

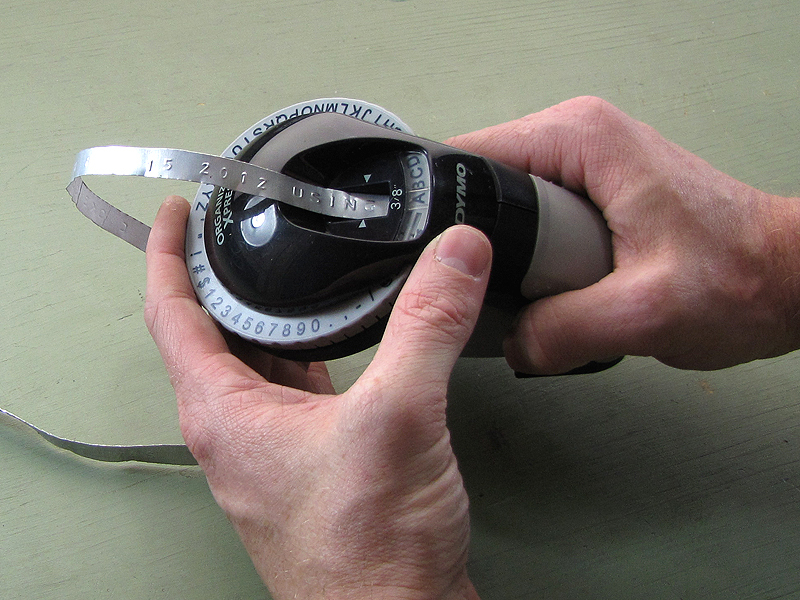

Positive response to the review of my antique Tapewriter label embosser got me thinking about lower-cost ways to make embossed aluminum labels. A comment from reader Rick Hyde (“Actually, the aluminum is so ductile that I bet any Dymo machine can emboss it.”) led me to wonder about feeding thin aluminum strip to one of the inexpensive “grocery store” label makers designed for plastic tape, and when I began looking for accessible sources of thin aluminum sheet metal my first thought was to use soda cans.

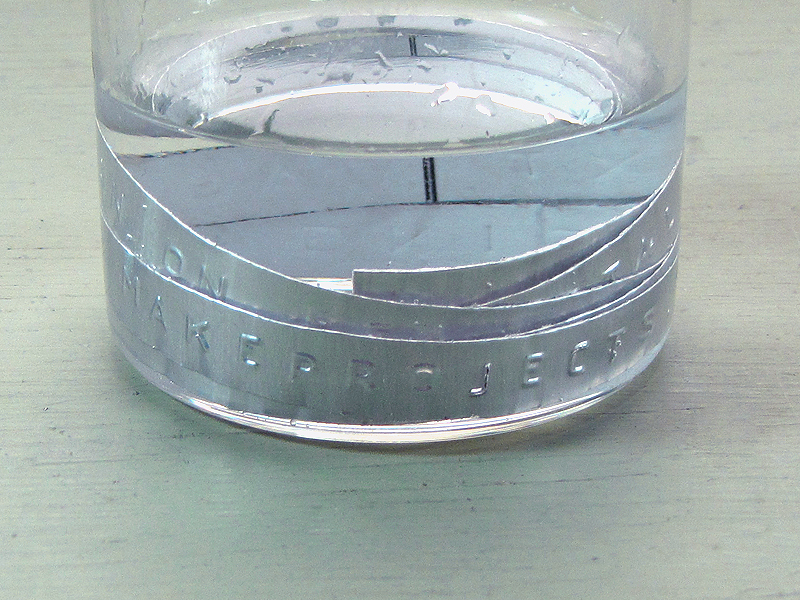

Experiment proved that yes, soda can metal embosses well enough in a plastic-tape embosser, but there were three problems:

- Cutting uniform strips of out of the side of a soda can was not easy.

- At 0.003″, soda can metal is much thinner than plastic embossing tape (0.011″), and does not advance reliably through the mechanism.

- Though the metal cut easily with scissors, doing so tended to raise burrs that interfered with smooth feeding.

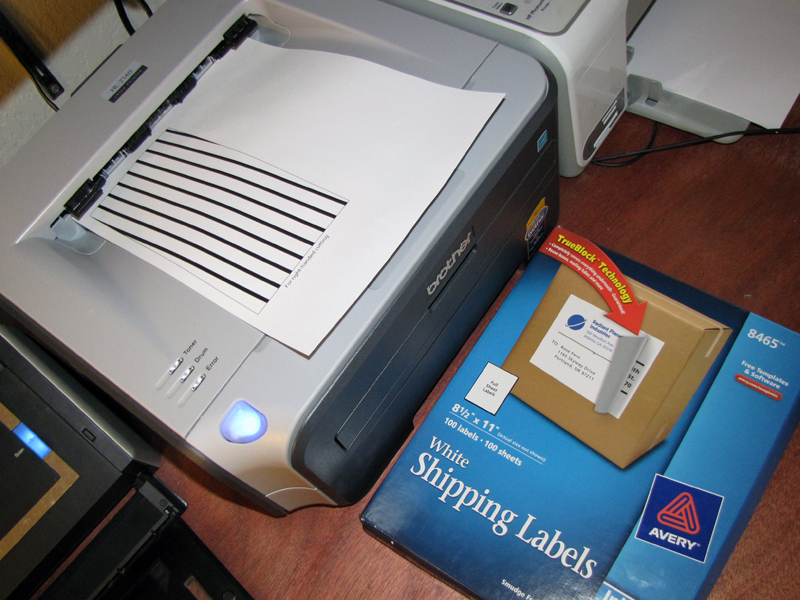

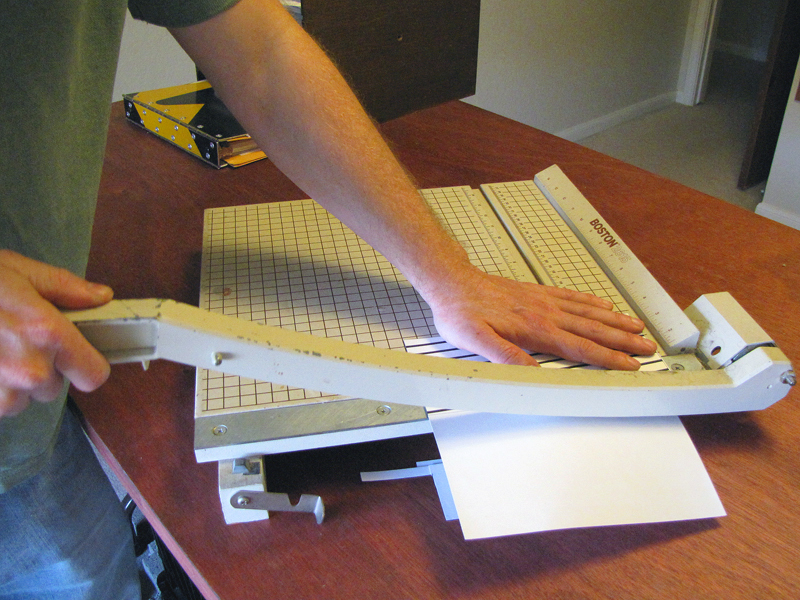

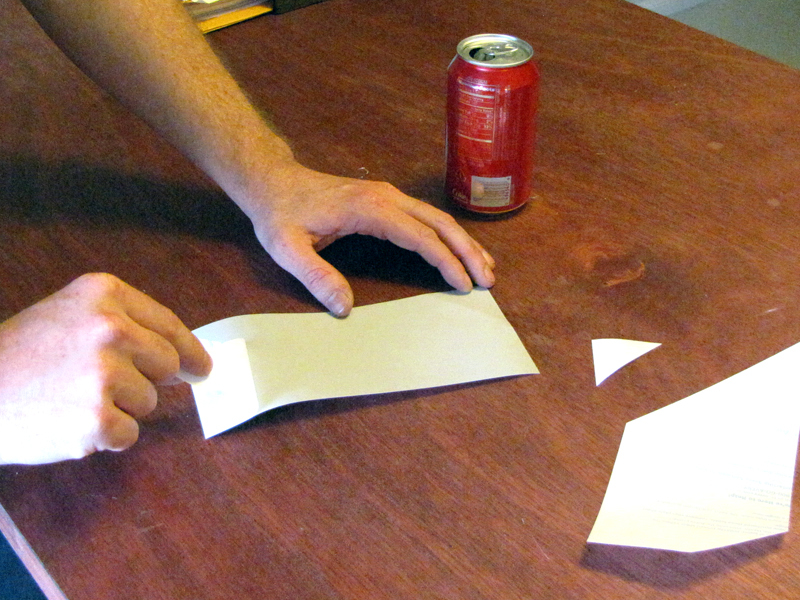

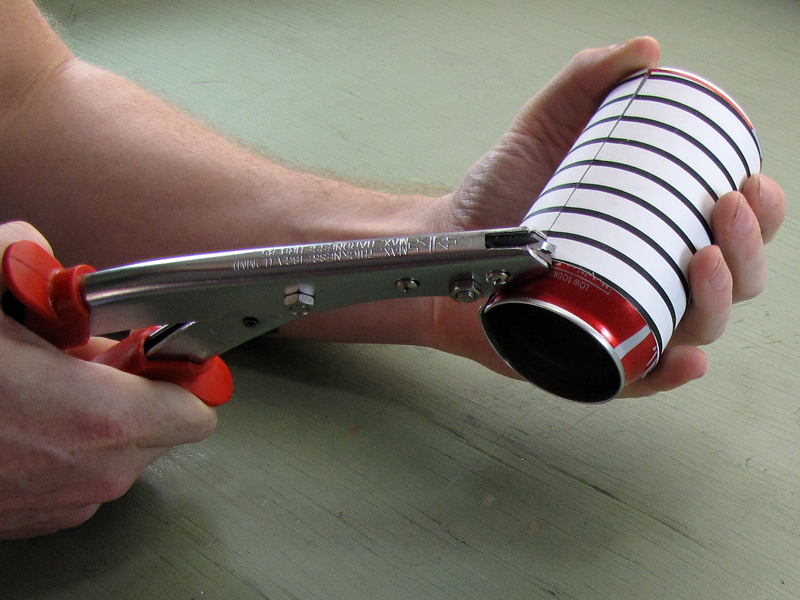

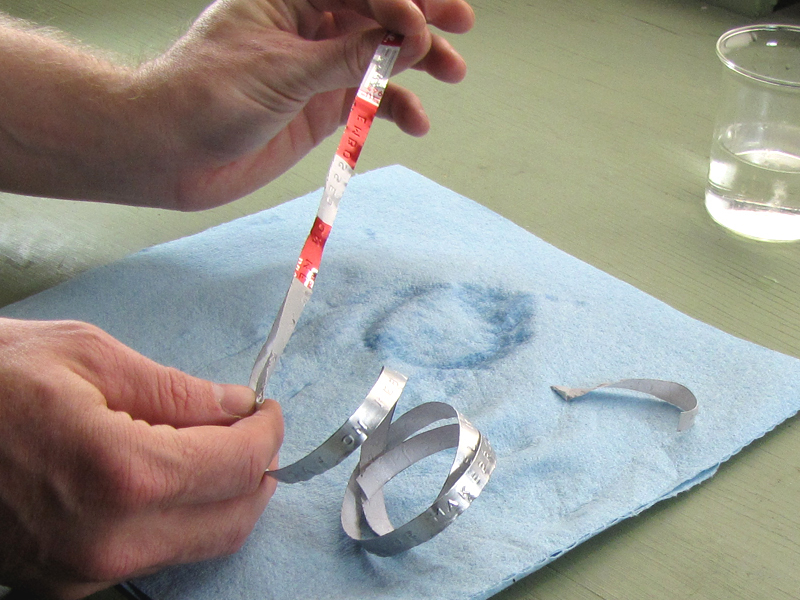

The first two problems were solved by using a spiral cutting template designed in software, printed onto an adhesive-backed label, and wrapped around the can before cutting. The template guidelines make it easy to cut a strip of uniform width, and the adhesive paper, if left in place during the embossing operation, brings the thickness up to 0.009″ and eliminates feeding problems.

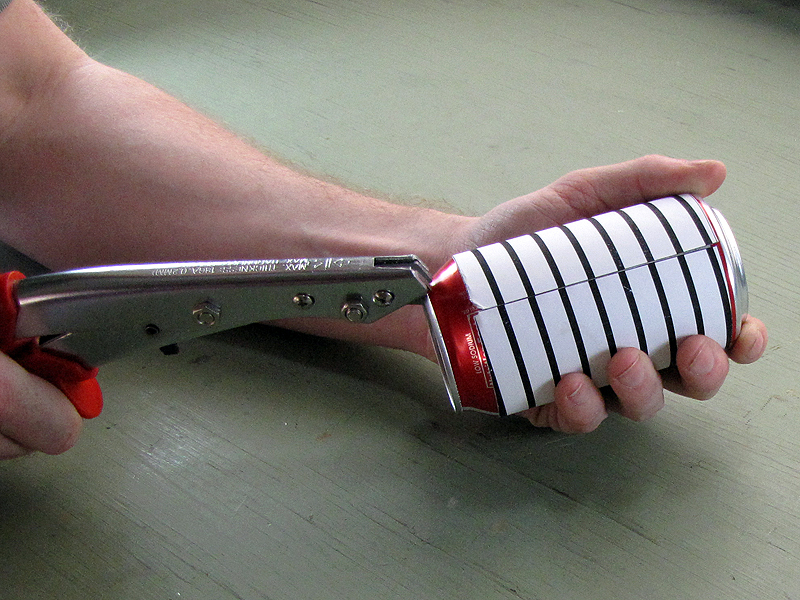

Finally, the burr-raising problem was solved by using nibbling shears, instead of scissors, to make the cut. A small burr is still produced, but it is easily smoothed by “stropping” the cut strip against a leather strap.