An oscilloscope, or o-scope, is the best friend of an electronics enthusiast, be they professional or hobbyist. While a digital multimeter can help you measure steady state and RMS (Root-Mean-Square) voltages, theoscilloscope can not only measure peak-to-peak voltages, but more importantly provide timing information on your signal.

For instance, have you ever been working with an Arduino controlling a servo motor that has to have just the right pulse width modulation in order to spin clockwise instead of counter-clockwise? During your programming, you may have wondered just how close the pulse width was to what was needed. With an oscilloscope you can measure these pulses. When dealing with analog signals, you can use an oscilloscope to see how close you are to the frequency you need or measure what frequency you need to filter. With so many digital electronic projects, timing between signals is extremely important. Therefore, having an oscilloscope is essential.

However, price can be an obstacle. Entry-level scopes can start off at a few hundred dollars. From there, higher-end scopes can end up into the tens of thousands. However, did you know that you probably have all you need to make your own oscilloscope? In fact, you are probably reading this on a device that has the essential parts needed. All other parts are probably in your parts bin.

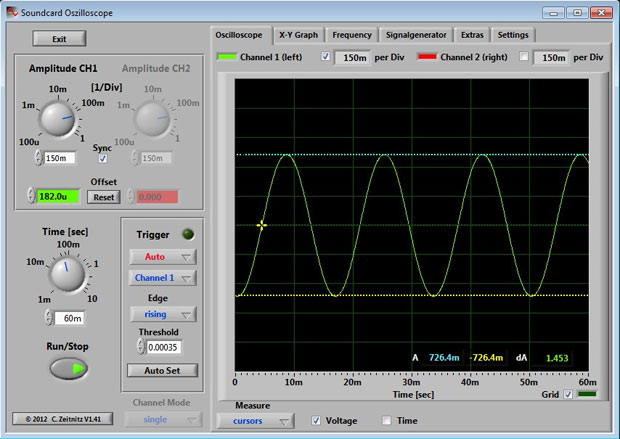

In essence, an oscilloscope is a data acquisition box that records the voltage from your circuit. Another device on your computer already does this: the sound card. The main differences are the level of voltage each can handle, and how fast they sample the voltage (more on that later). Since the sound card on your computer can only handle a small amount of voltage (around +/- .6V to .8V) you need to scale it down. Building your own scope probes accomplishes: allowing input of higher voltages and scaling the voltage down so the sound card can handle it.

The steps below outline how to build such a probe. The probe being built here is used with the line input of a sound card. Line inputs typically accept stereo inputs, therefore this probe will have two channels. If you’re thinking of using the mic input on your system, you will want to build just one channel as mic inputs typically are mono. After the build, I’ll show you some comparisons of this oscilloscope to a lab-grade model and discuss some limitations.

Much of this project is adapted from http://homediyelectronics.com/projects/howtomakeafreesoundcardpcoscilloscope, and the software can be found http://www.zeitnitz.de/Christian/scope_en.