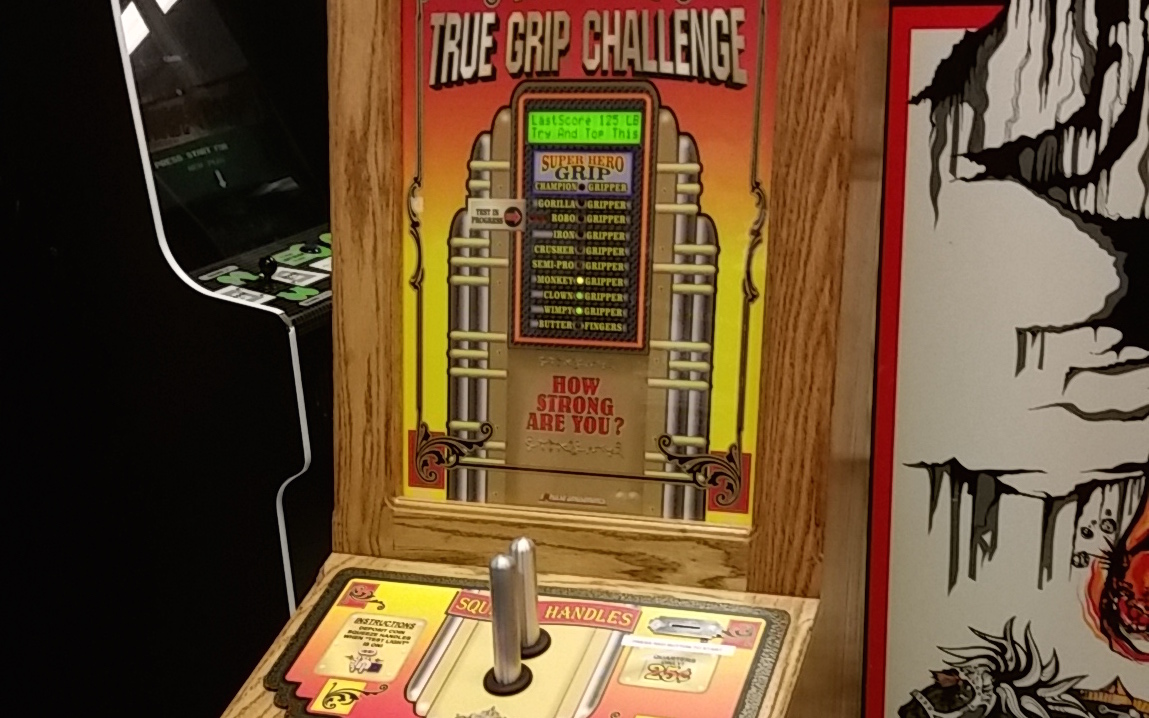

The Grip Challenge used to be a popular game in carnival midways, encouraging guys (mostly) to flaunt their strength by squeezing a pair of handles together. Figure A shows a version you can still find in some amusement arcades. It sells for almost $2,000 new — so I decided to build my own.

To measure the gripping force, I used strain gauges, which work on the principle that the resistance of a conductor increases fractionally when you stretch it. A typical strain gauge uses the configuration shown in Figure B, in which parallel conductors multiply the effect.

When 4 strain gauges are glued to the topside and the underside of a bar of aluminum, you have a load cell of the type shown in Figure C. The pairs of gauges are wired in a configuration known as a Wheatstone bridge, in Figure D.

An actual load cell is shown in Figure E. Almost always, the power input wires are red and black, while the output wires are green and white. Load must only be applied in the direction of the arrow printed on the bar, and causes the voltage on the green wire to increase while voltage on the white wire decreases. The voltage difference is the output from the cell, expressed in millivolts per volt at maximum load. For example, if a 50kg cell is rated at 1.1mV/V, and you energize it with a 9V battery, the output will reach 9.9mV when the load increases to 50kg.

Breakout boards are available to interface a load cell with a microcontroller, but it’s cheaper and easier to use a couple of analog chips. A basic LM741 op-amp can amplify the voltage from the cell, while a quad-comparator LM339 will light 4 LEDs in succession as the load increases.

Figure F shows the schematic laid out for easy breadboarding. The pinouts of the LM339 make it convenient to place at the top of the circuit. I also added a toggle switch and 3mm “power on” LED with 1.5K current-limiting resistor (not shown).

I chose a 20kg load cell for this project, but higher values up to 50kg can be used by adjusting the mechanical leverage in your Grip Challenge design. Test the cell by screwing one end into a hefty piece of scrap wood, including washers to allow room for the cell to flex. Most load cells have metric threads, but you can drill them out to provide room for your choice of screws or bolts.

Apply 9VDC to the red and black wires, set your meter to measure millivolts, and use a screw clamp to increase the force on the free end of the load cell (Figure G). If it is rated around 1mV/V (which is typical), tighten the clamp till you measure 9mV. This tells you that the cell is now experiencing its maximum load.

Leave the clamp in place while you disconnect your meter and connect the green and white wires to the op-amp. Using the component values in my circuit, the output from pin 6 of the LM741 should be around 6.3V. If you measure less than that, substitute a larger value for the 100K feedback resistor. If it’s more than 6.5V, use a lower-value feedback resistor, because the comparators in the LM339 cannot compare voltages that rise too close to the power supply.

To provide reference voltages for the comparators, I put 5 resistors in series as a voltage divider. The values 680K, 33K, 47K, 33K, and 330K provide reference voltages of approximately 5.0V, 5.3V, 5.7V, and 6.0V. As the output from the op-amp increases from 4.5V with no load to 6.3V with maximum load, it passes each of the reference voltages and triggers the next comparator, which lights another LED. You can experiment with different resistor values if you wish.

Because the LM741 is sensitive to stray electromagnetic fields, twist the wires from the load cell together to prevent unwanted flickering of the LEDs.

To mount your circuit permanently, you’ll need hardwood to withstand the forces involved. I made a heavy-duty oak box, shown under construction in Figure H. One handle is fixed while the other pivots around the round dowel.

I moved the dowel up and down to adjust the leverage of the handles until I needed all my strength to trigger the fourth LED. After that, I made a permanent pivot for the handle and glued the box together using a biscuit joiner (Figure I).

Going Further

If you build your own version, you can challenge people to a strength contest — which can be serious or not-so-serious. To fool your friends, add a hidden switch connecting a second 100K feedback resistor in parallel with the first. This will reduce the power of the op-amp, making it physically impossible for anyone to light the fourth LED (except you, of course). I think people should expect a bit of trickery when they play carnival midway games.

In addition to load cells, many other types of force sensors exist. You can learn more about them in my Encyclopedia of Electronic Components, Volume 3, published by Maker Media.