I have wanted to weave since I can remember, but I always thought it was impossible because of space constraints. Then I got my hands on a tapestry loom!

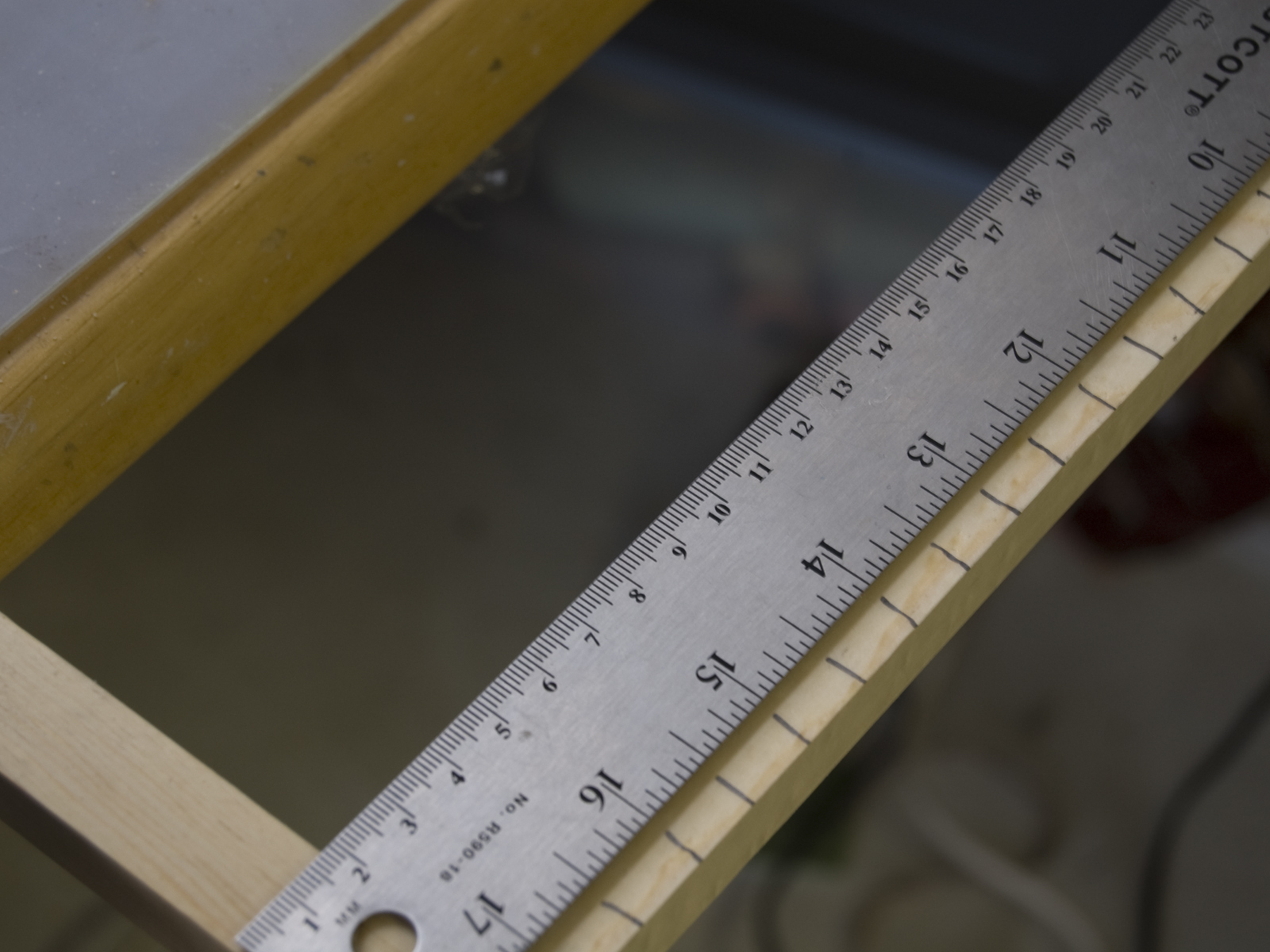

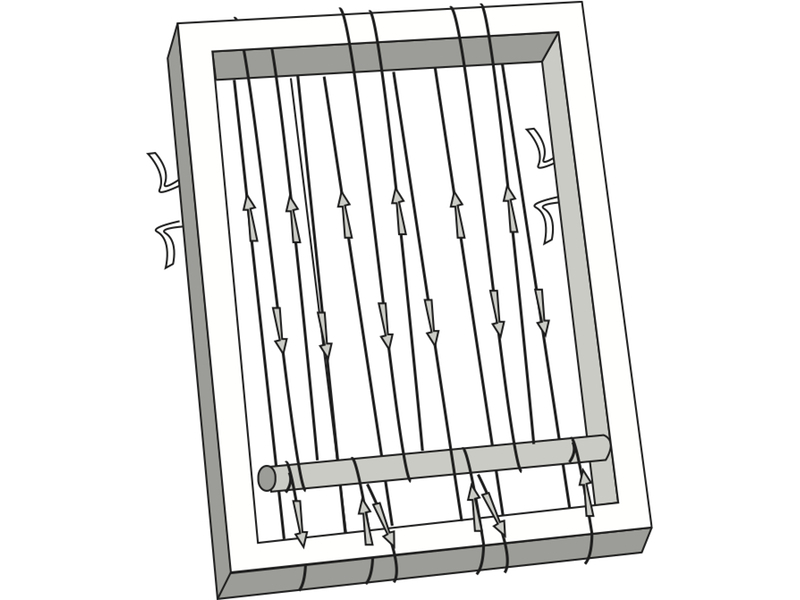

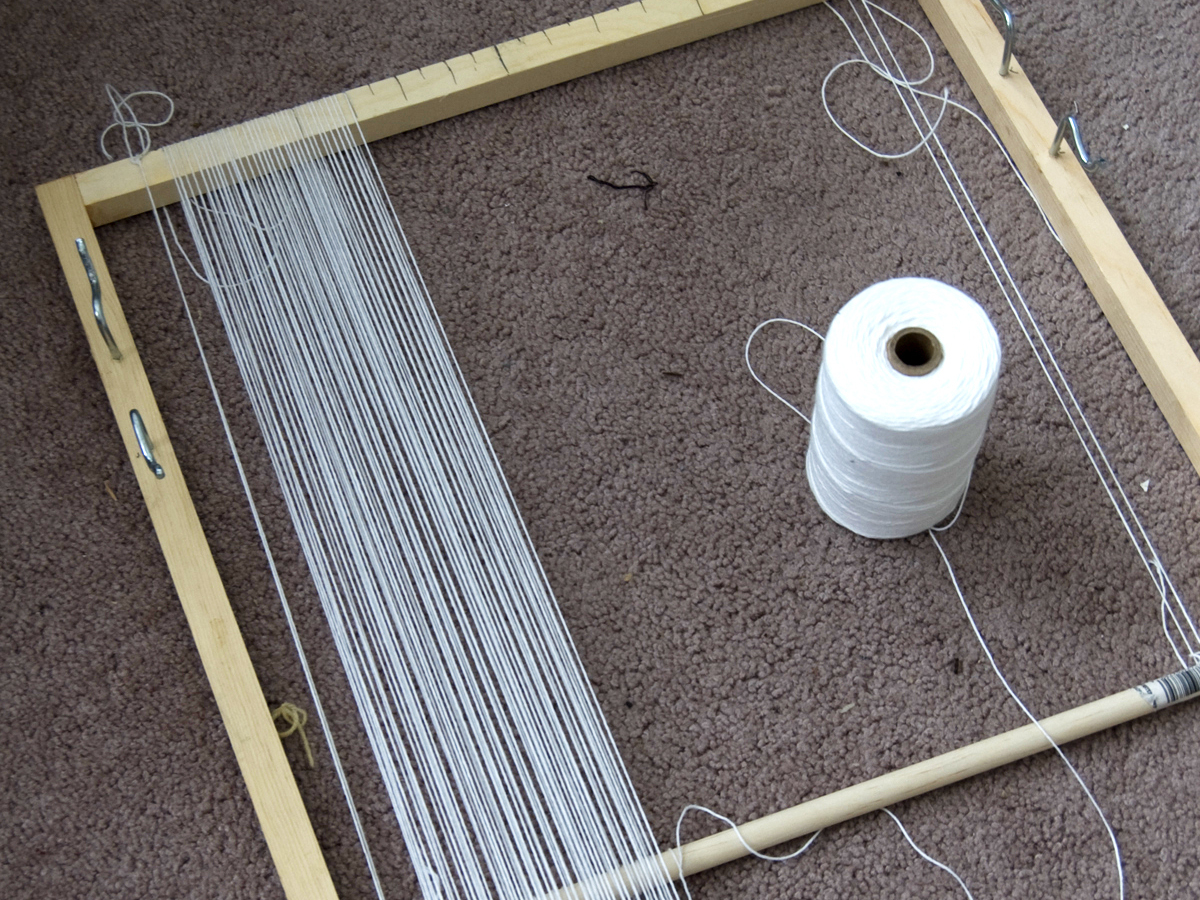

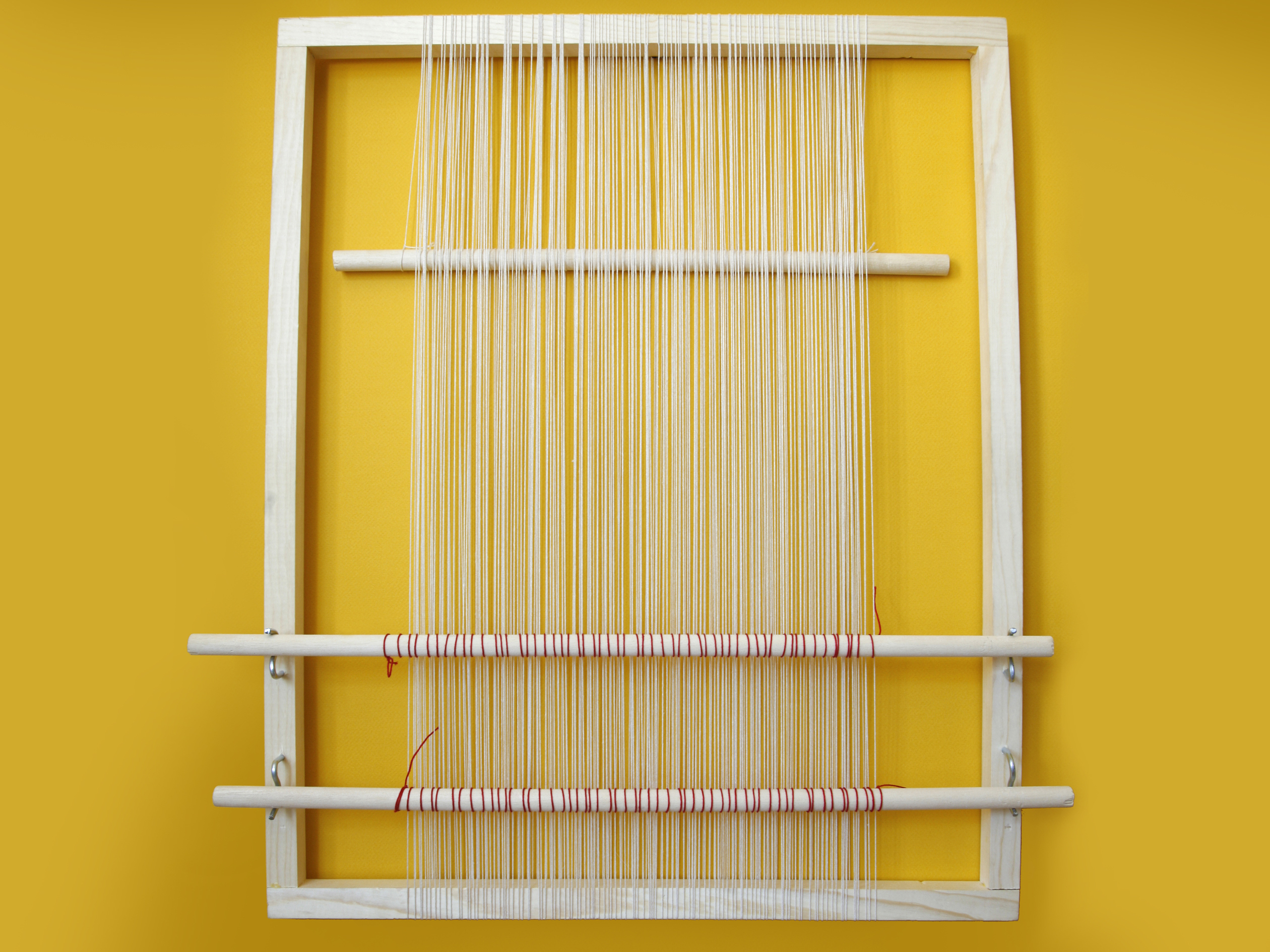

With a tapestry loom you’re able to weave the full length of warp because it’s wrapped around the frame. You actually shift the warp bar, and therefore the warp, around the whole frame. So even though the loom is only 22″ tall, you have 40″ of workable warp! With the use of 2 heddle bars, it’s easy to open up 2 sheds for all sorts of tapestry weaving adventures. The materials cost less than $20, and it takes about 20 minutes to make the loom’s frame and then 2 to 3 hours to warp it.

You can make your loom any size. I have looms ranging from 8″×10″ to 18″×22″; just remember that if you go larger than that, you need to build your frame from wood that is at least 1″×2½” or the tension of the warps will, well, warp your frame. I have even snapped a few frames, not a fun experience at all.