Attach the piston to its lever arm, and slide the lever arm into position on the crankshaft. It’ll take some wiggling. Slide the crankshaft through the middle hole on the crankshaft stand you glued down. Next, slide the lever arm for the displacer rod onto the crankshaft, and attach it to the displacer rod (you may need to bend the bottom hook). Slide the second crankshaft stand onto the shaft and line it up. We still don’t want to glue it in place until we’re done tuning the engine.

Turn the crankshaft. Does anything hang up? If the piston isn’t pumping properly, is it lined up where you marked it? If not, remove it and twist the lever arm until it lines up.

When turning the rod, can you complete a full rotation? If not, check the displacer disk. Does it move all the way up and down? If it’s trying to go too high, move the crankshaft down 1 hole on the stand. If too low, raise it 1 hole. If it doesn’t make a complete turn because it’s trying to go too high and too low, bend shallower cams on the crankshaft. Bend deeper cams if there’s too much of a gap.

If it turns over nicely, drill a hole the same size as your rod in the center of your peanut butter lid. This is your flywheel. Push it onto the end of the crankshaft closest to the piston cylinder. It should be a snug fit. Don’t glue it yet.

You can also use a CD for a flywheel. Just mold an epoxy disk in the center, and drill out an attachment hole.

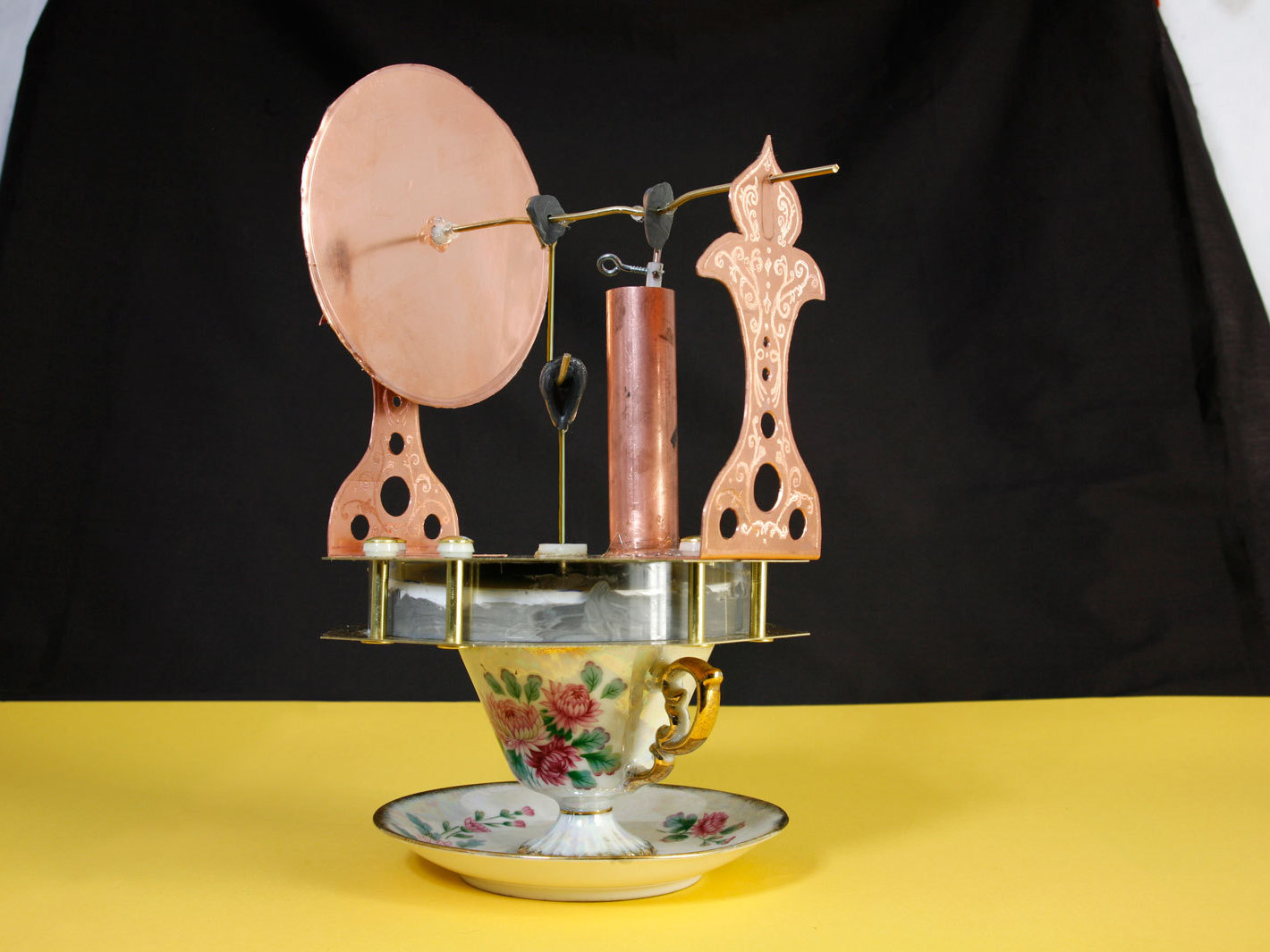

Now, the moment of truth. Apply heat to the bottom of the displacer assembly. Does it work? Try different heat sources: hot tea, coffee, votive candles, a tin filled with alcohol. Obviously, don’t melt the plastic displacer ring with too much heat. Turn the shaft and see what happens. One direction should be significantly easier than the other; this is the way your engine runs. After the metal heats for a bit, your engine will either not run at all, or it will kind of move but the piston won’t move as high and low as it could. Or it’ll run perfectly.

If performance is sluggish, make sure all your glue joints are airtight. Also, make sure nothing is snagging or hanging up. Add oil to the moving parts and try again. And finally, try making the piston’s cam shallower. You can also put ice cubes on the cold plate to increase the temperature differential.