For many years I have been searching for temperature-recording equipment. There were a lot of types available, such as old paper chart recorders. For computers there are various types, some expensive, single-channel, DIY units requiring programming, ADC (Analog to Digital Converters) with poor voltage sensitivity at thermocouple levels, and requiring a power supply to take records.

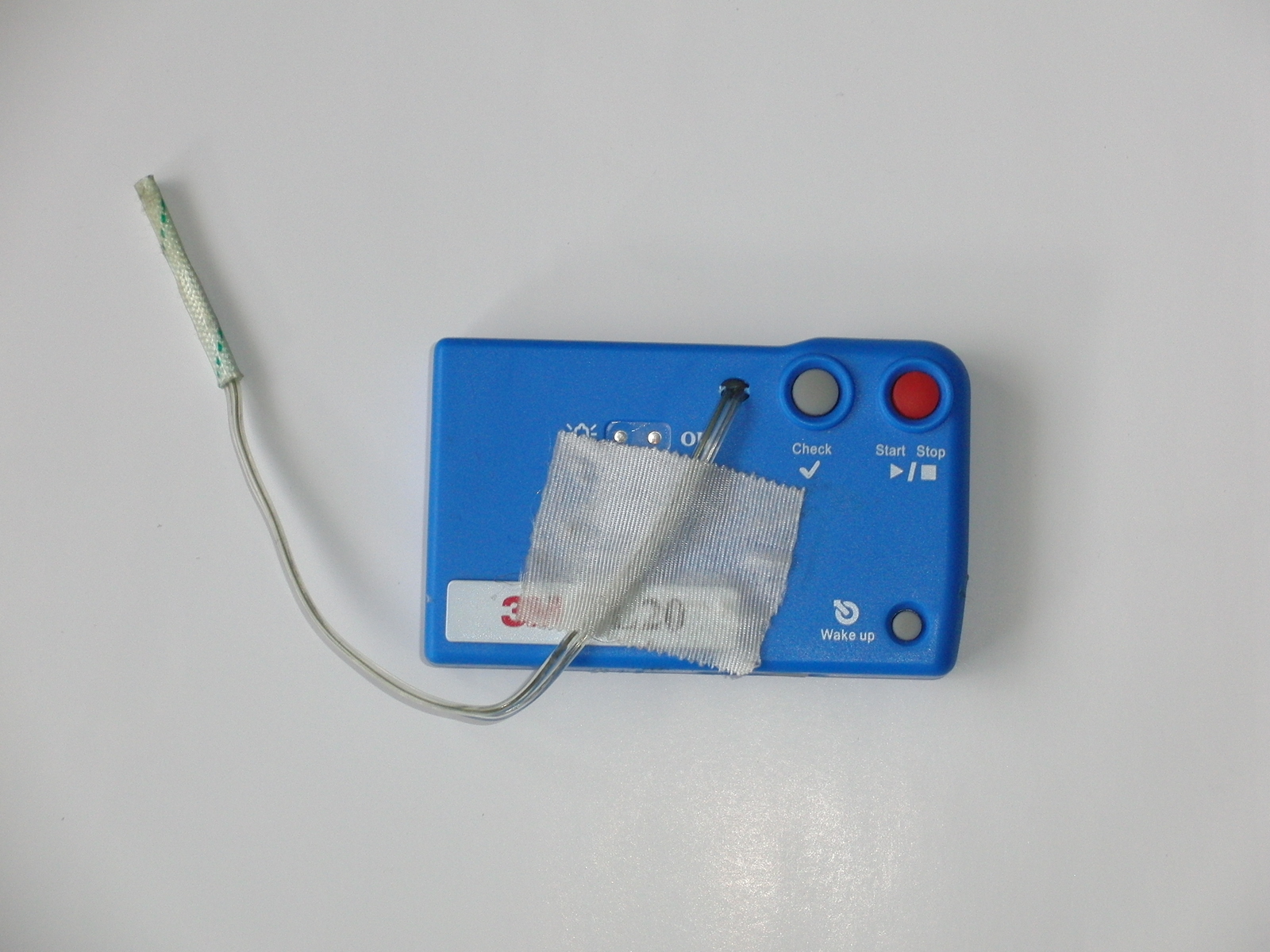

I came across the 3M temperature logger while looking through an office stationery supplies catalog. They are usually packed with heat-sensitive goods in a parcel for posting.

The temperature logger records the temperature at user-set intervals. The parcel’s recipient can download the recorded log with a special USB cable.

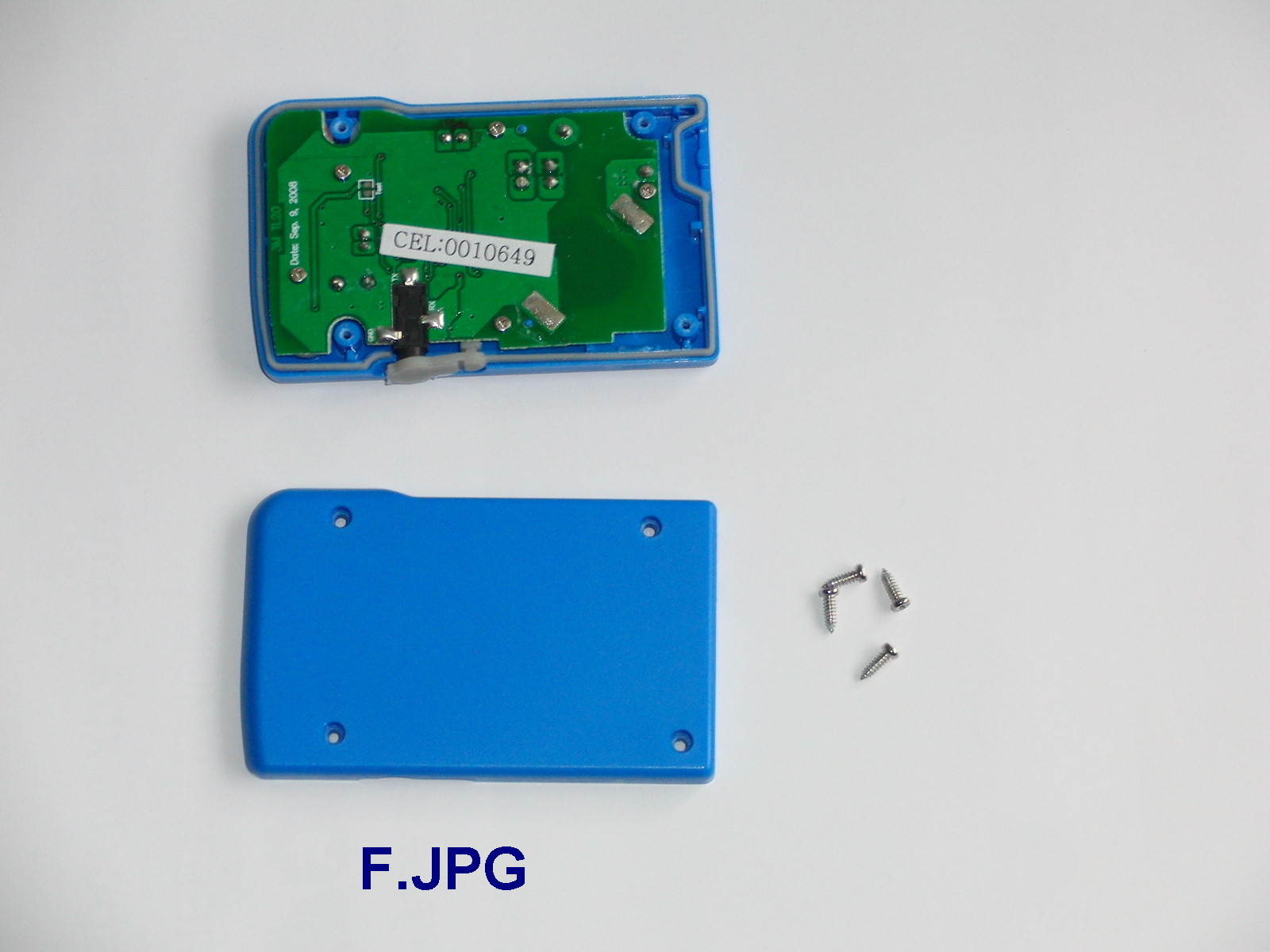

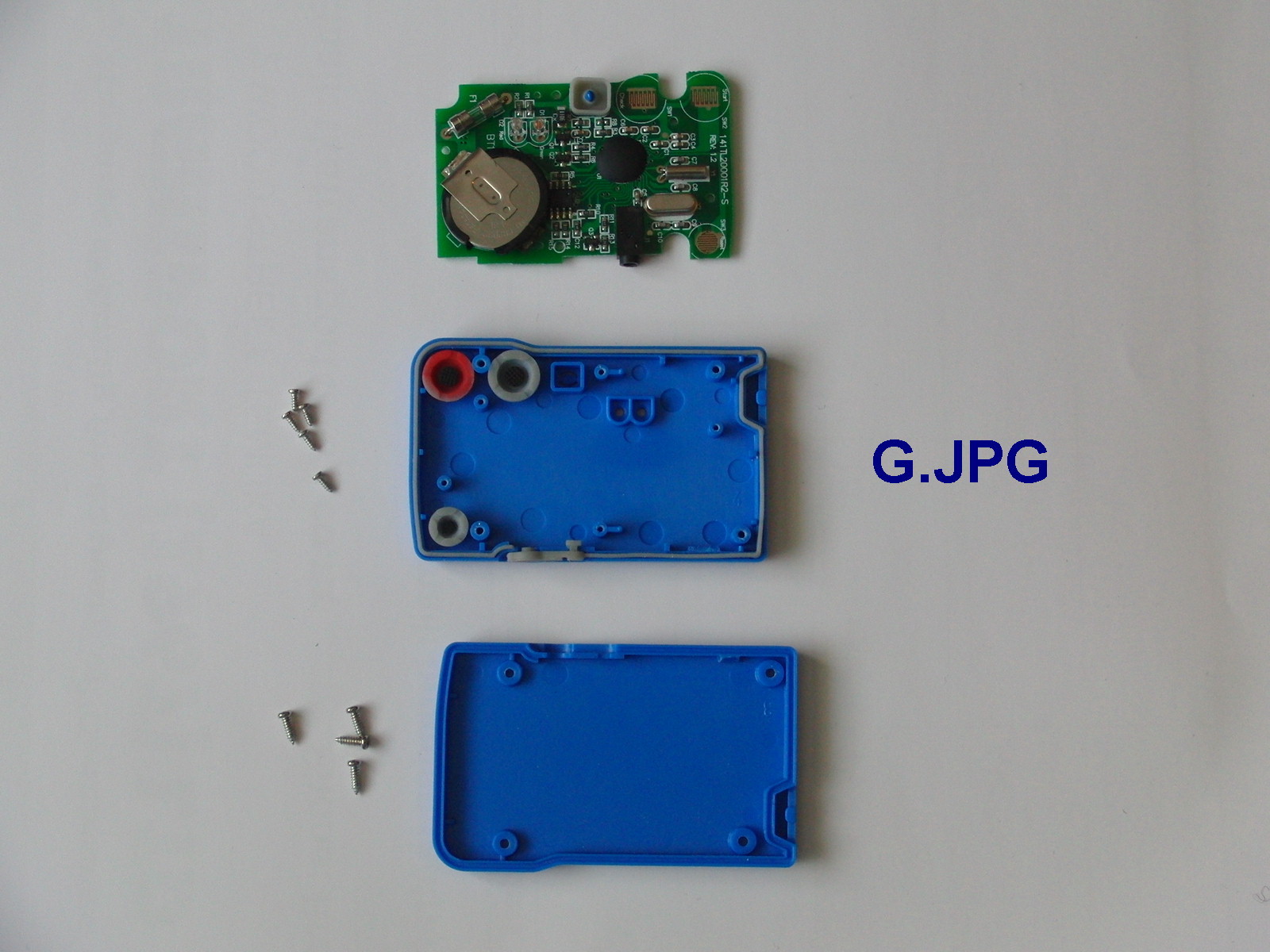

The temperature loggers come in boxes of five, and require the special USB cable which comes in a bag of two. (The newer TL30 uses a miniUSB socket). The loggers contain a battery.

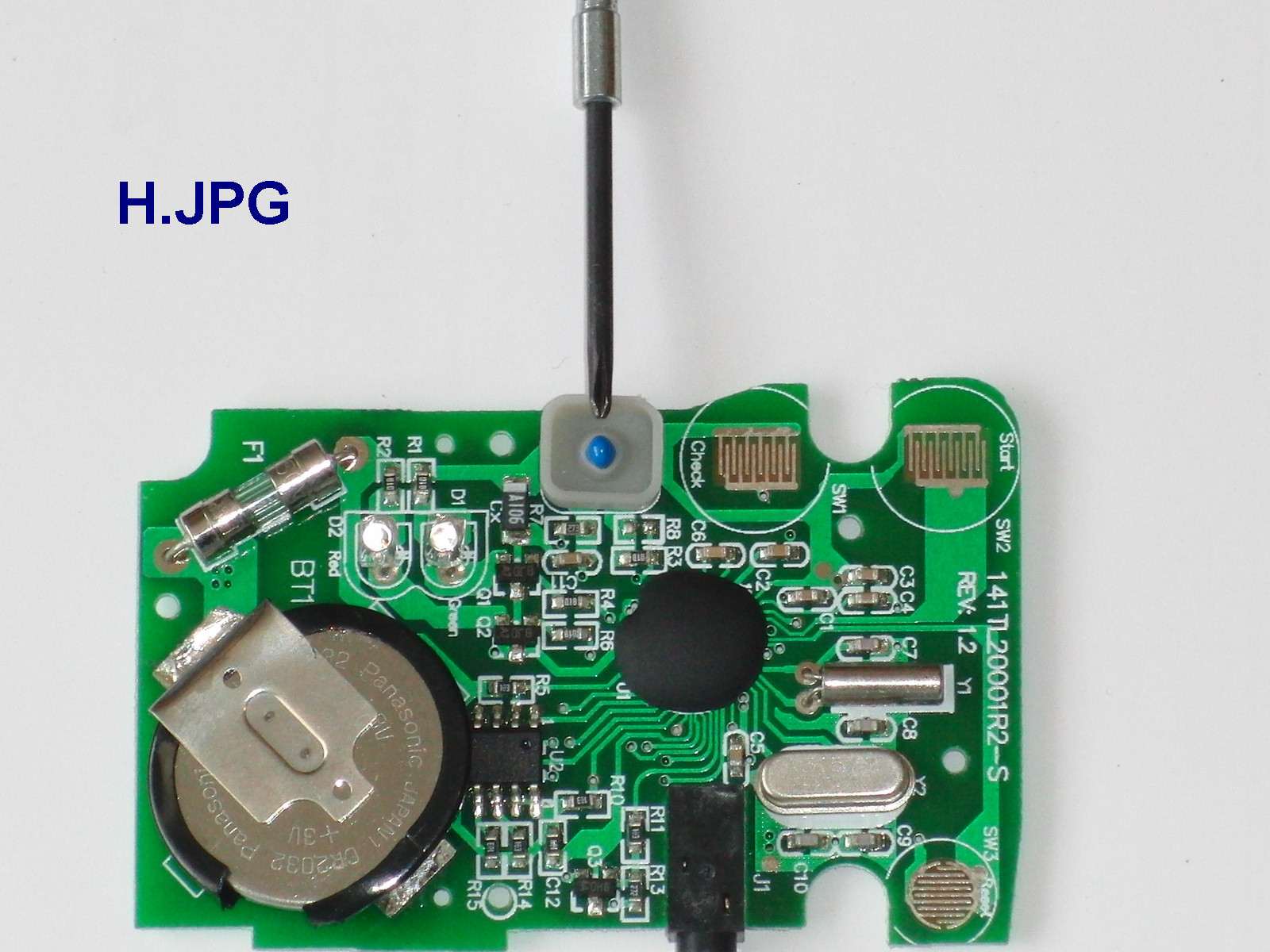

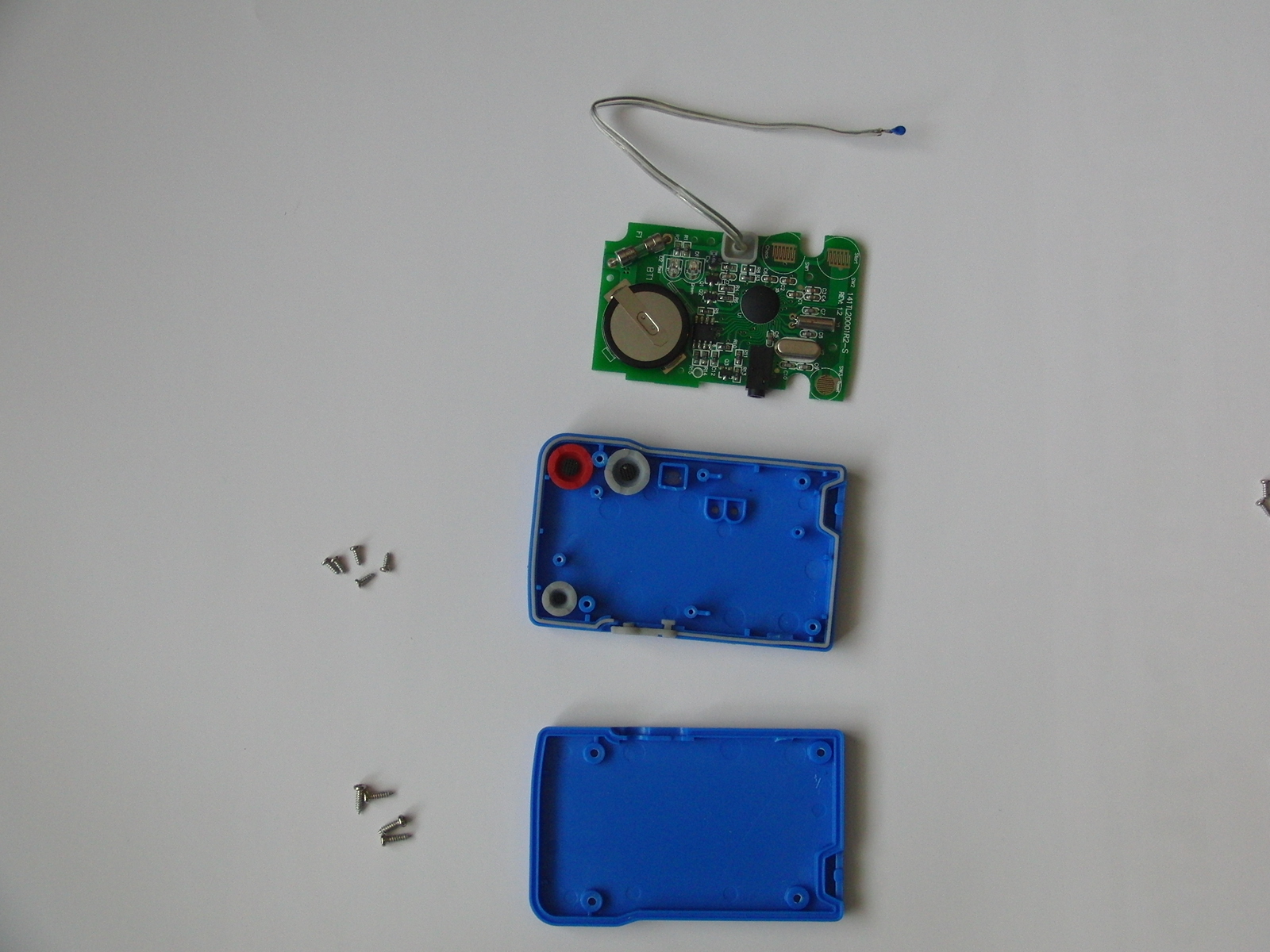

One limitation of the TL20 temperature loggers is their +60°C (140°F) maximum temperature. This is a limitation of the case and battery. The sensor can measure far higher — up to around 140 °C.

The logger’s features make it practical to measure temperatures in factory situations and school laboratory experiments. Each logger will record up to 30 minutes.

I also used an electric roast-temperature probe that was supplied with a microwave oven. It is designed for +200°C (392°F) with silicone-covered cable. The thermistor inside has a different resistance and reads an estimated +38 °C under actual.

To make measurements in liquids such as water, the sensor will need covering. The logger case can be located safely away from what is being measured.

Note: Leaving the logger plugged into the USB cable will drain its battery.

Having 5 loggers allows simultaneous measurement of ambient temperature and 4 more areas.

On a machine such as a 3-way absorption refrigerator, you can use one inside the freezer, one on the middle radiator, one on the top radiator, and the most heatproof on the generator element. Place them carefully so as not to damage the machine.

A whole range of effects can be measured, such as:

- Insulation losses

- Maximum hot/cold, etc.

- Temp vs. time factor, when heating freshwater ice, showing temperature increase is not linear (at the change-of-state points)

- Is coffee hotter when milk is poured in first? Or did the boiling water cool quicker when poured into a cold china mug?

- The enthalpy of evaporation.