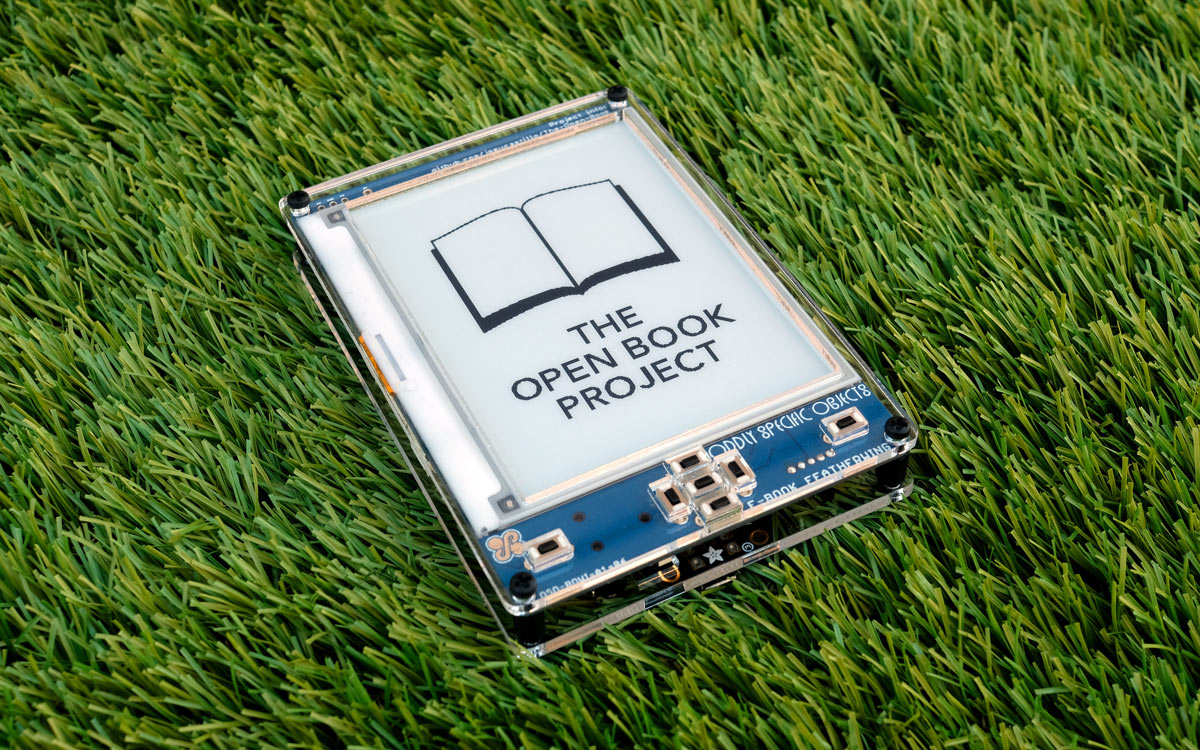

Handheld gadgets surround us, but often these slabs of glass and silicon feel like they arrive fully formed in our lives. We don’t often get the chance to understand how, say, a Kindle works — or even better, how we might make one ourselves! The Open Book Project aims to create a simple, comprehensible device for reading texts in all the languages of the world — an e-reader that can be built by hand with the tools in the average maker’s workshop.

The E-Book FeatherWing is the simplest version of the build. Functionally it’s a “wing” — an accessory board that pairs with an Adafruit Feather M4 Express, which provides the microcontroller and the battery charging circuitry. Almost all of the E-Book wing’s surface-mount parts are reasonably large and easy to solder by hand, which makes it a great project for getting started with surface-mount soldering.

In this guide, you’ll build your own E-Book FeatherWing. With its 4.2″ e-paper screen and seven clicky buttons on the front, it’s a great device for reading, but it’s also a highly capable platform for doing more! You can use it to play sound from the headphone jack, display sensor data from the trio of STEMMA ports, or even stack an AirLift FeatherWing to connect to the internet.