There are two ways to mount the wobble disk on the shaft: with a small bracket or with two short pieces of aluminum tubing.

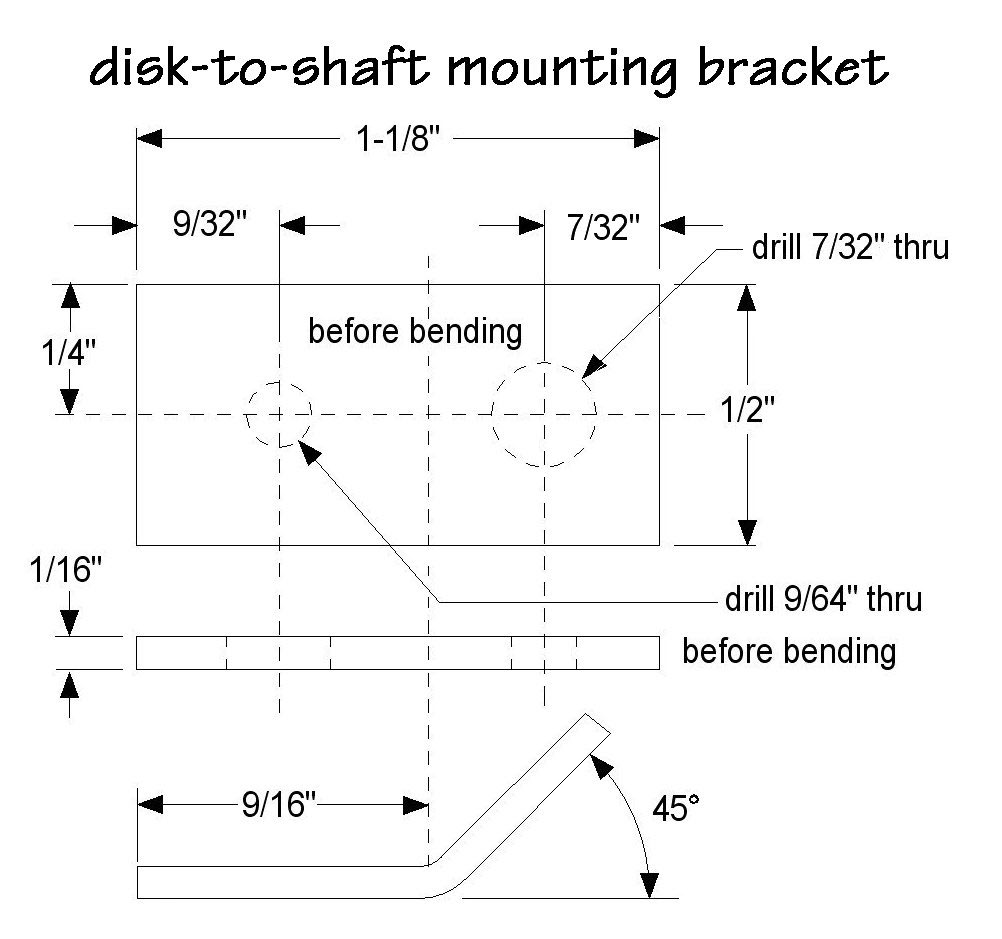

3a. If you have a small piece of 1/16″-thick aluminum, make a disk-mounting bracket to the diagram. If you don’t have the aluminum, skip to Step 3b.

Push the disk about halfway down the shaft. Thread a 10-24 nut until it touches the disk. Push the bracket over the shaft until its longer (bent) end is flush with the disk. Mark on the disk through the small hole in the bracket, remove the bracket, and drill a 9/64″ hole where you marked it.

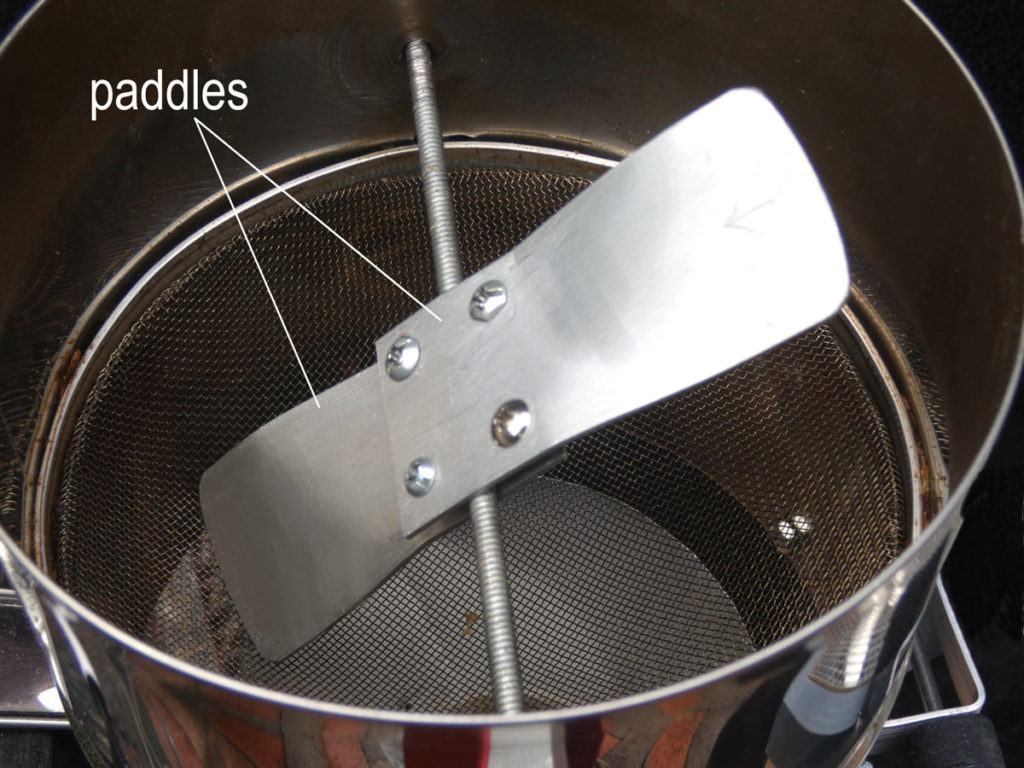

Put the parts back onto the shaft in the same order, then fasten the disk and bracket together with a ¼”-long 6-32 Phillips screw and nut (Figure E). Go to Step 3c.

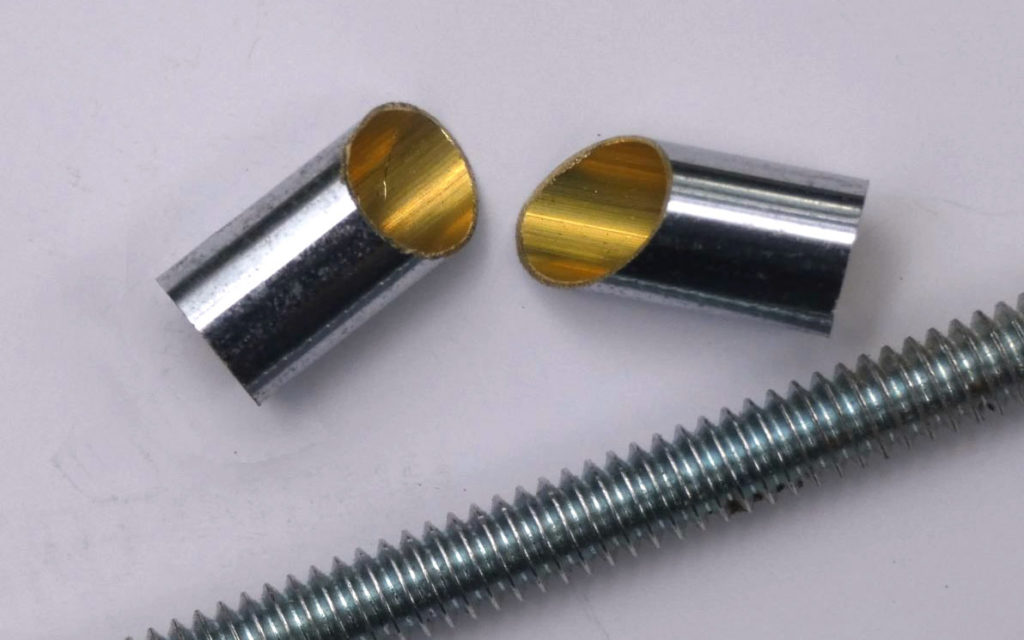

3b. For this disk attachment method, use 1″ or so of approximately ¼” ID aluminum tubing. Cut with a hacksaw two roughly ½” lengths, each with a 90° and a 45° end. One 45-degree hacksaw cut is all that’s necessary.

Thread one 10-24 nut onto the shaft near the middle. Slip one piece of the aluminum tubing onto the shaft to the nut, with the angled end away from the nut. Slip the disk onto its shaft and seat it against the angled face of the tubing.

Add the second short piece of tubing (angled end first) so the disk is trapped at a 45° angle. It’s OK for the tubing pieces to be slightly askew relative to the shaft!

3c. Regardless of the disk-holding method, thread another 10-24 nut onto the shaft so that it traps the disk as close to the center of the shaft as possible. Holding both nuts with wrenches or pliers, tighten them until the disk is firmly mounted.

Figure B shows the tubing method holding the disk. If your tubing material is slightly too big in diameter, add #8 washers between the nuts and the pieces of tubing.