The original LED lanterns were featured in MAKE: Magazine, issue 30. When I first saw the article, I thought that they could only be used once, as they would have to be glued shut. When I read it, I realized that they were sealed with tape, and could therefore be opened, but not before I came up with a new idea.

Projects from Make: Magazine

Upgraded Indestructible LED Lanterns

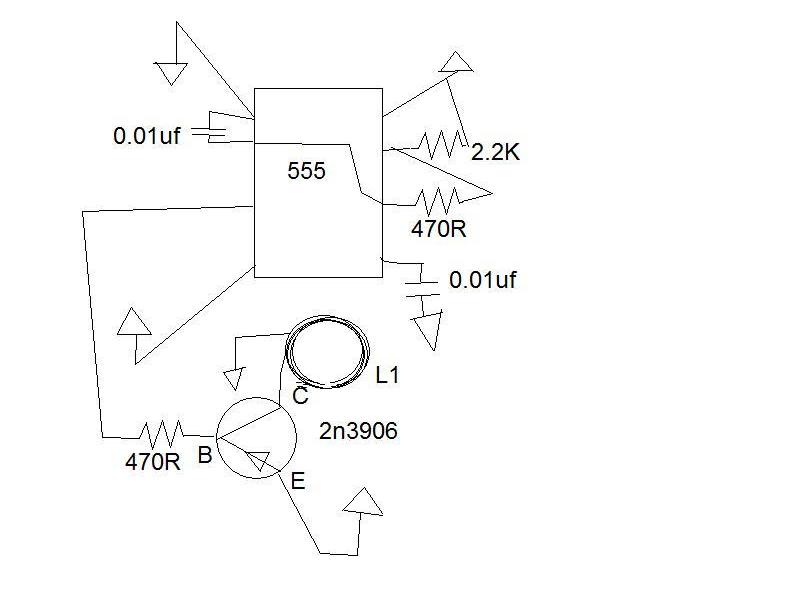

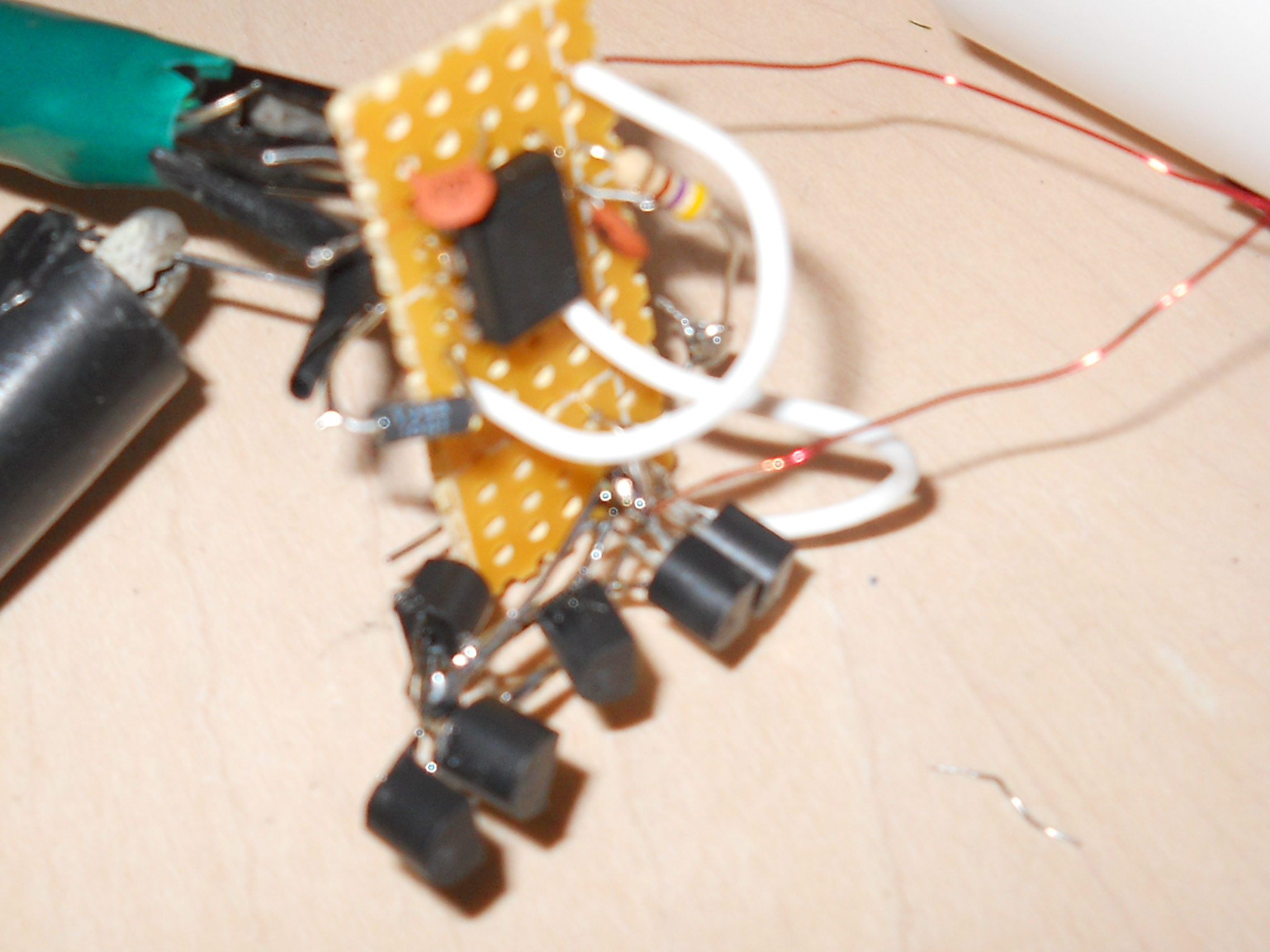

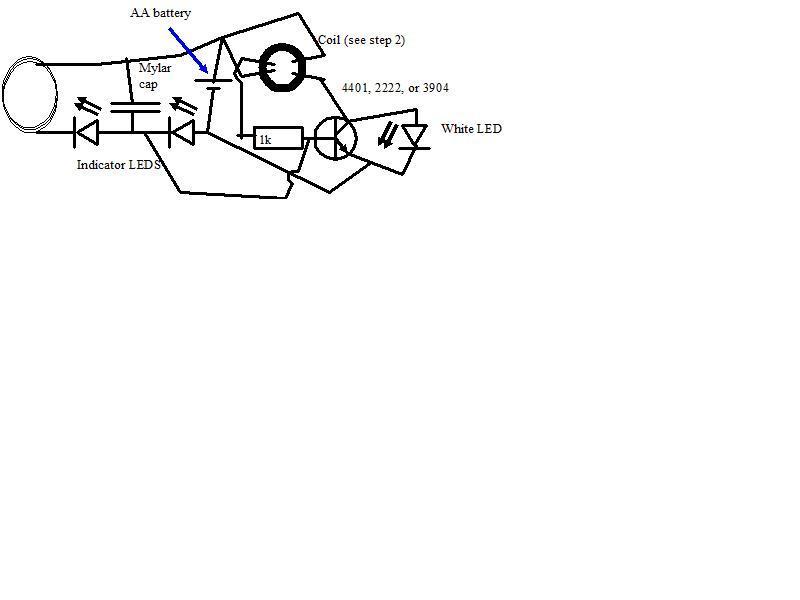

This guide shows how to build a rechargable LED lantern that is virtually indestructable, charges wirelessly, and is very cheap. This project was featured on Designnews.com. Check it out at http://www.designnews.com/author.asp?section_id=1362&doc_id=2