When I first started building homemade instruments, I used a piezoelectric buzzer from RadioShack as a pickup (see http://onestringwillie.com for details). But while it’s cheap and simple, the piezo transducer has downsides: it has a low signal output, it picks up a lot of handling noise and can go into uncontrollable feedback at high volume, and it sounds thin and not nearly as authoritative as an electromagnetic pickup.

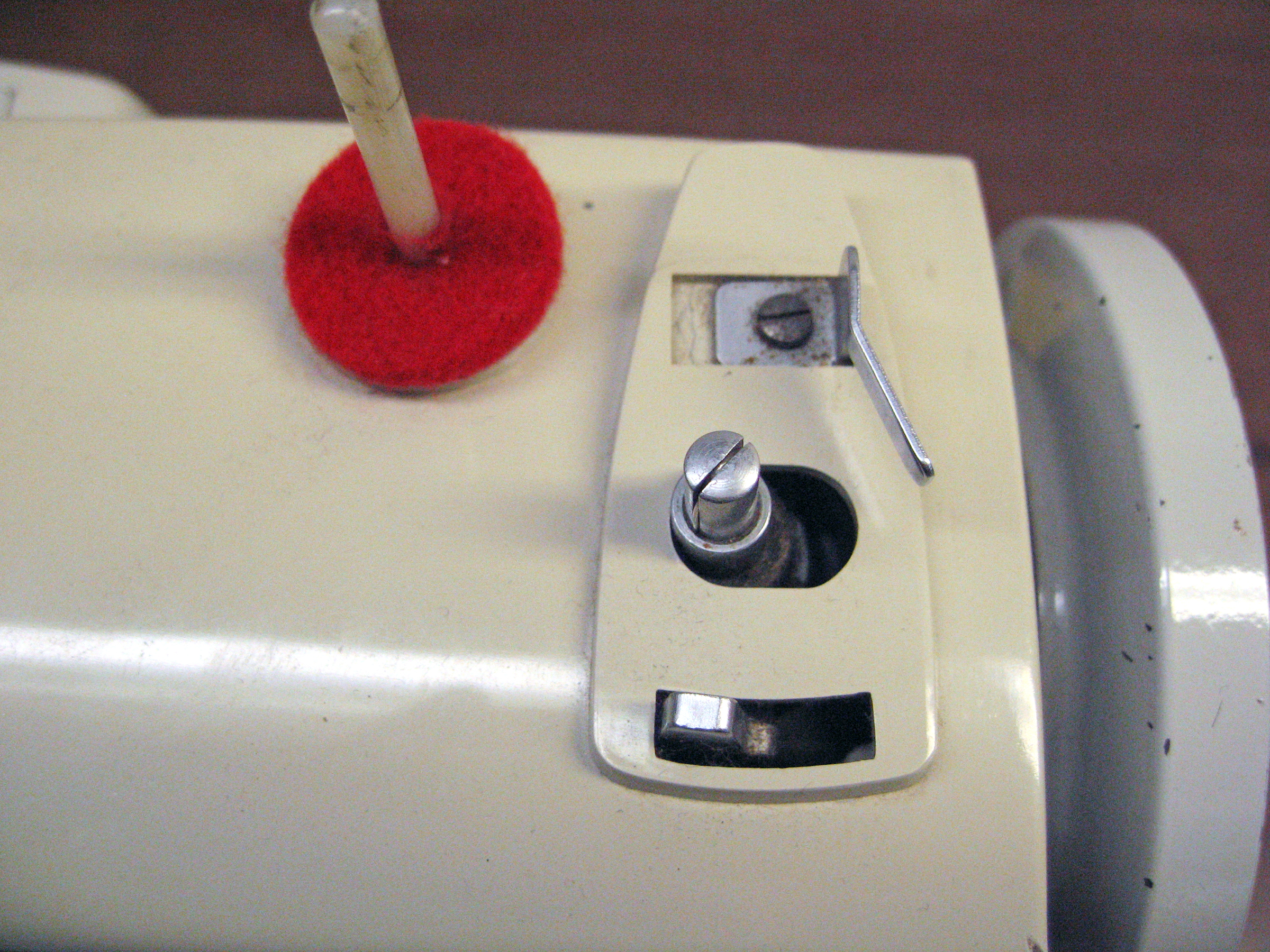

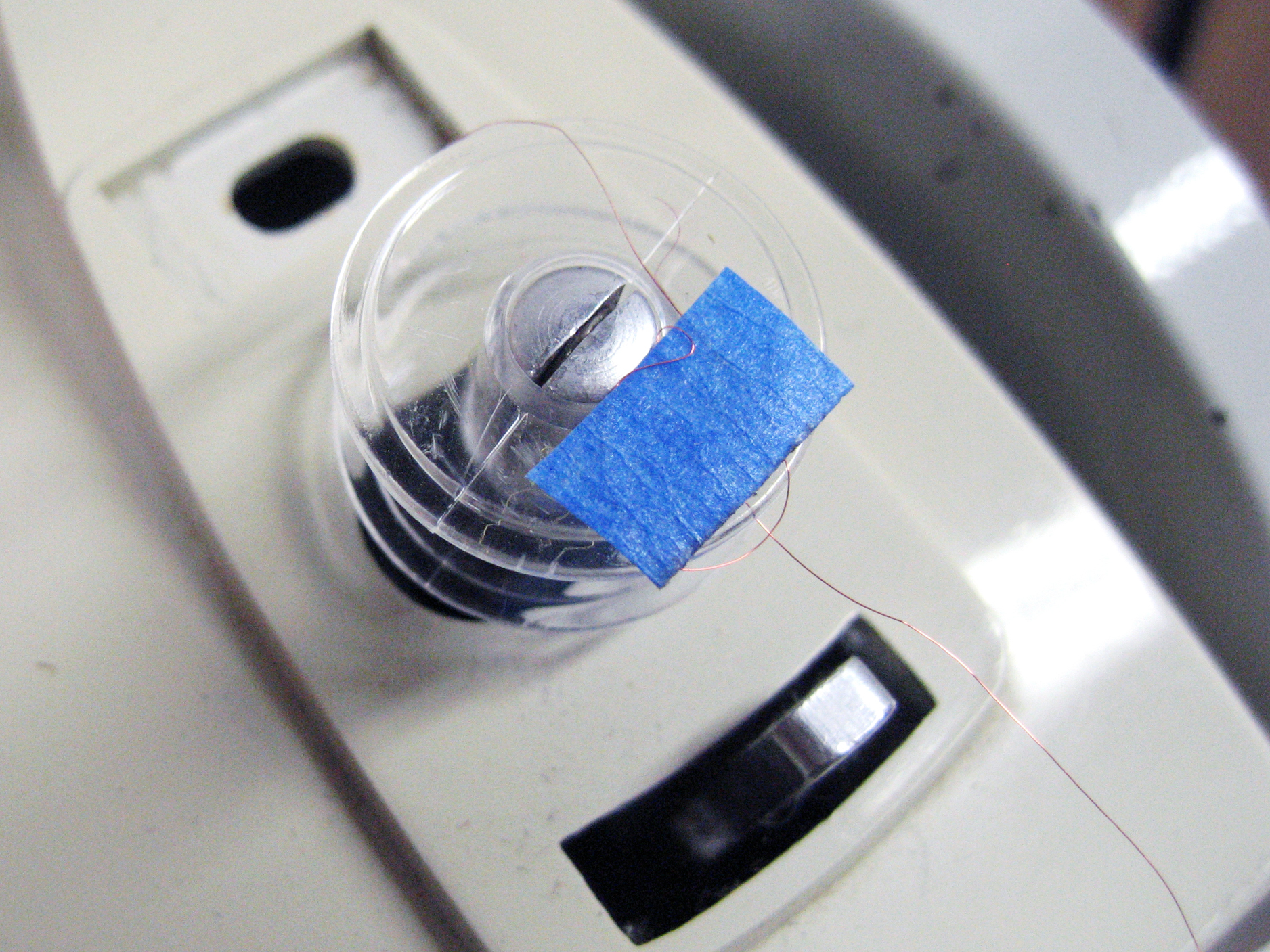

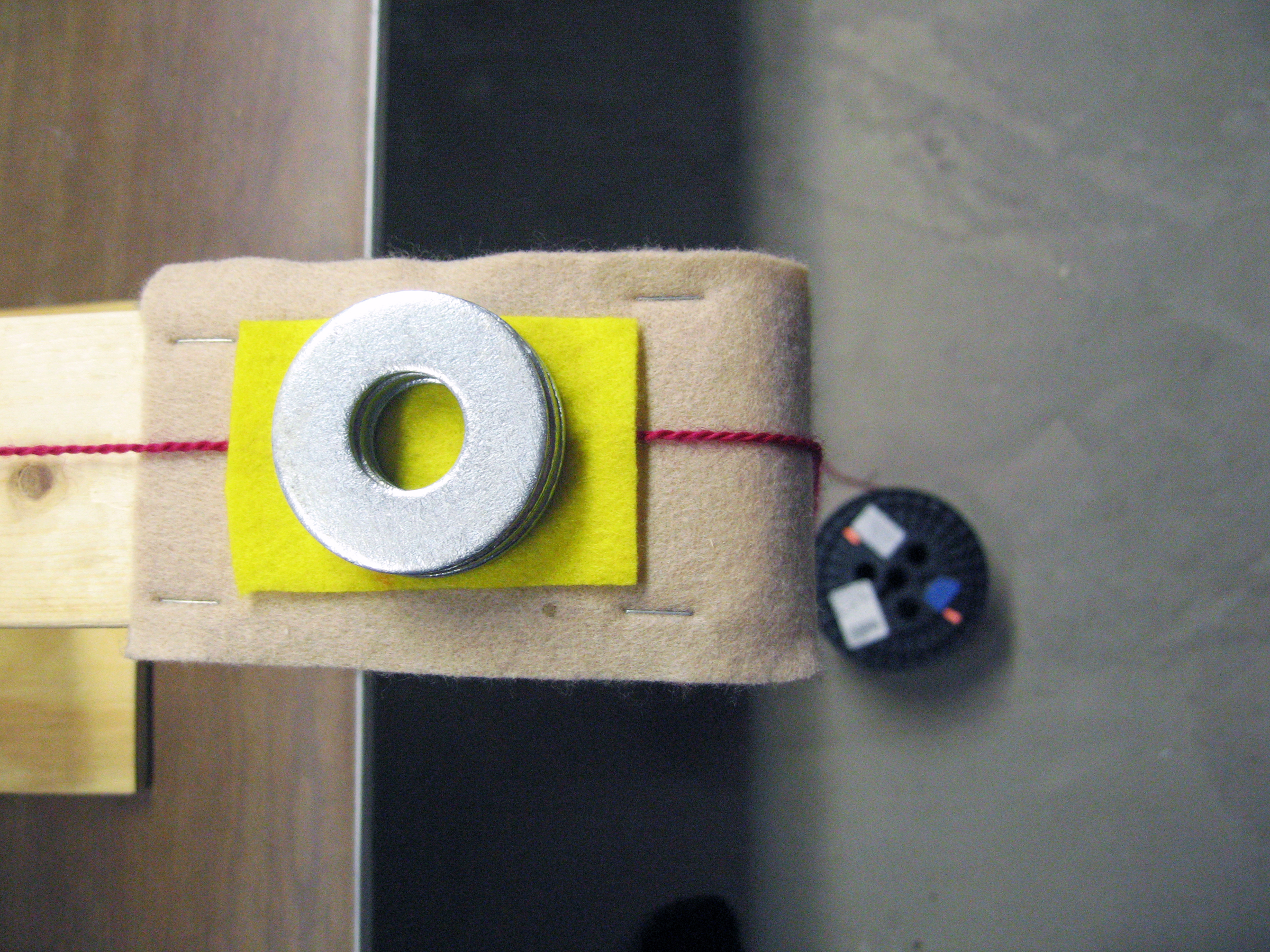

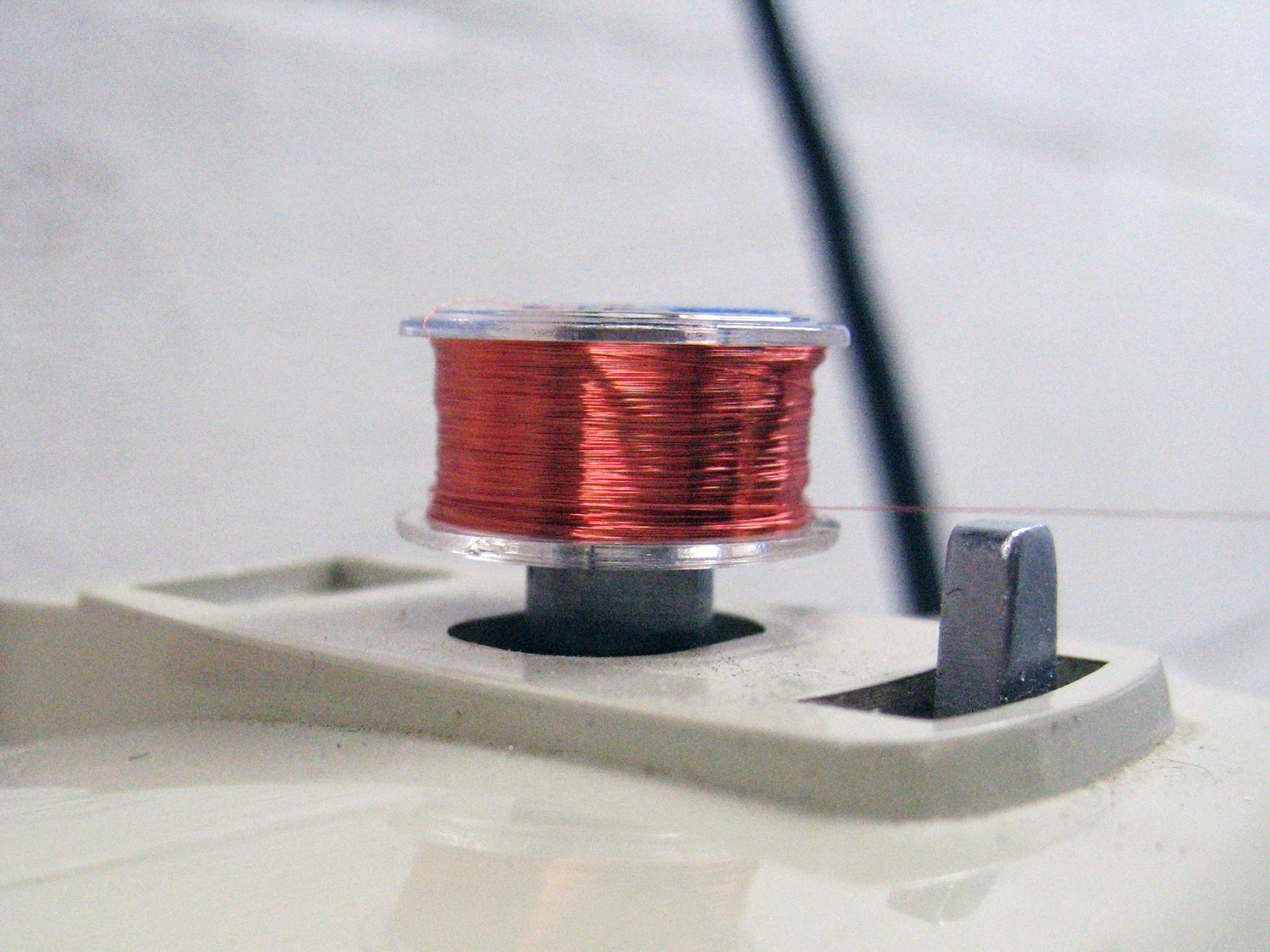

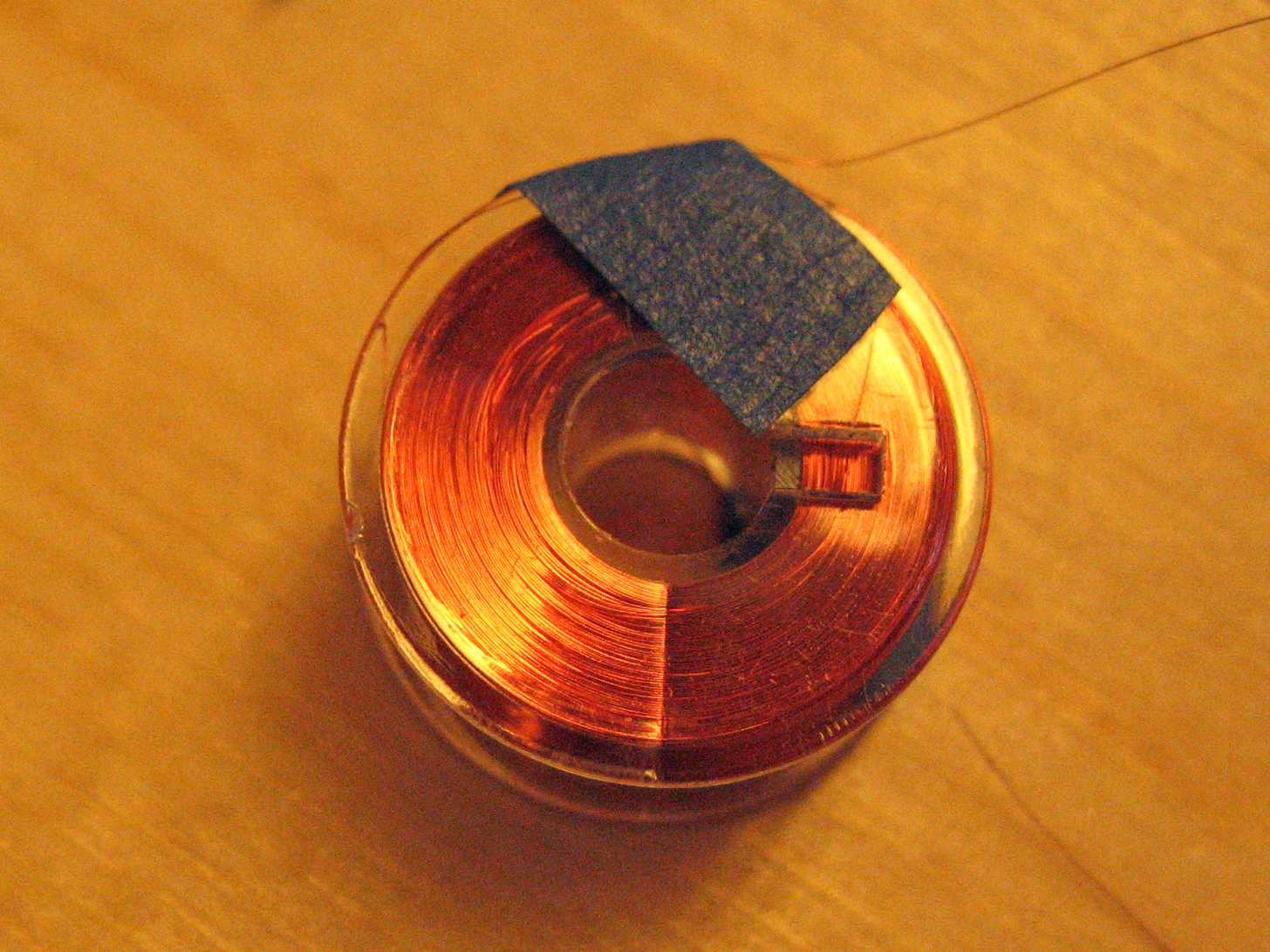

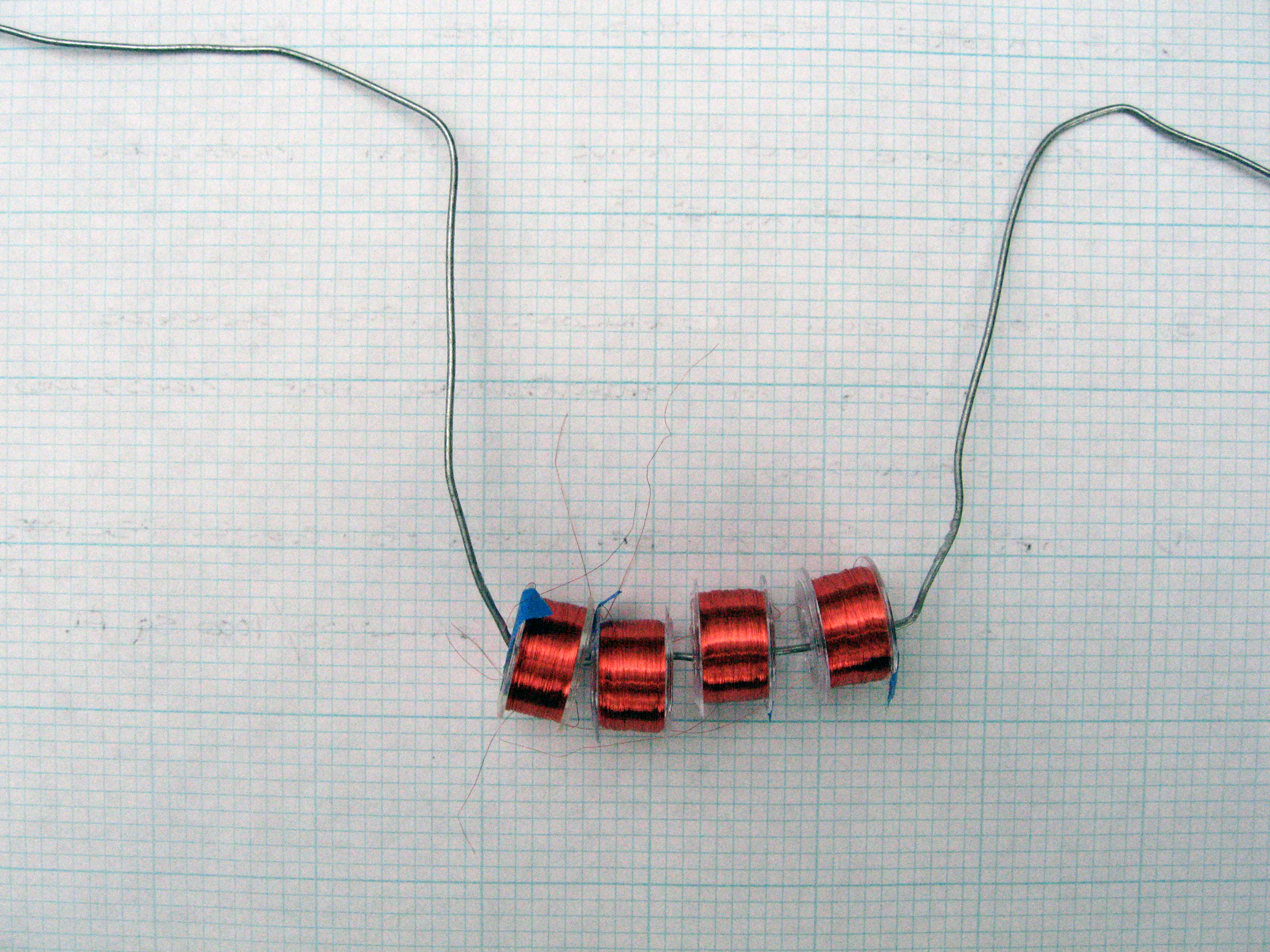

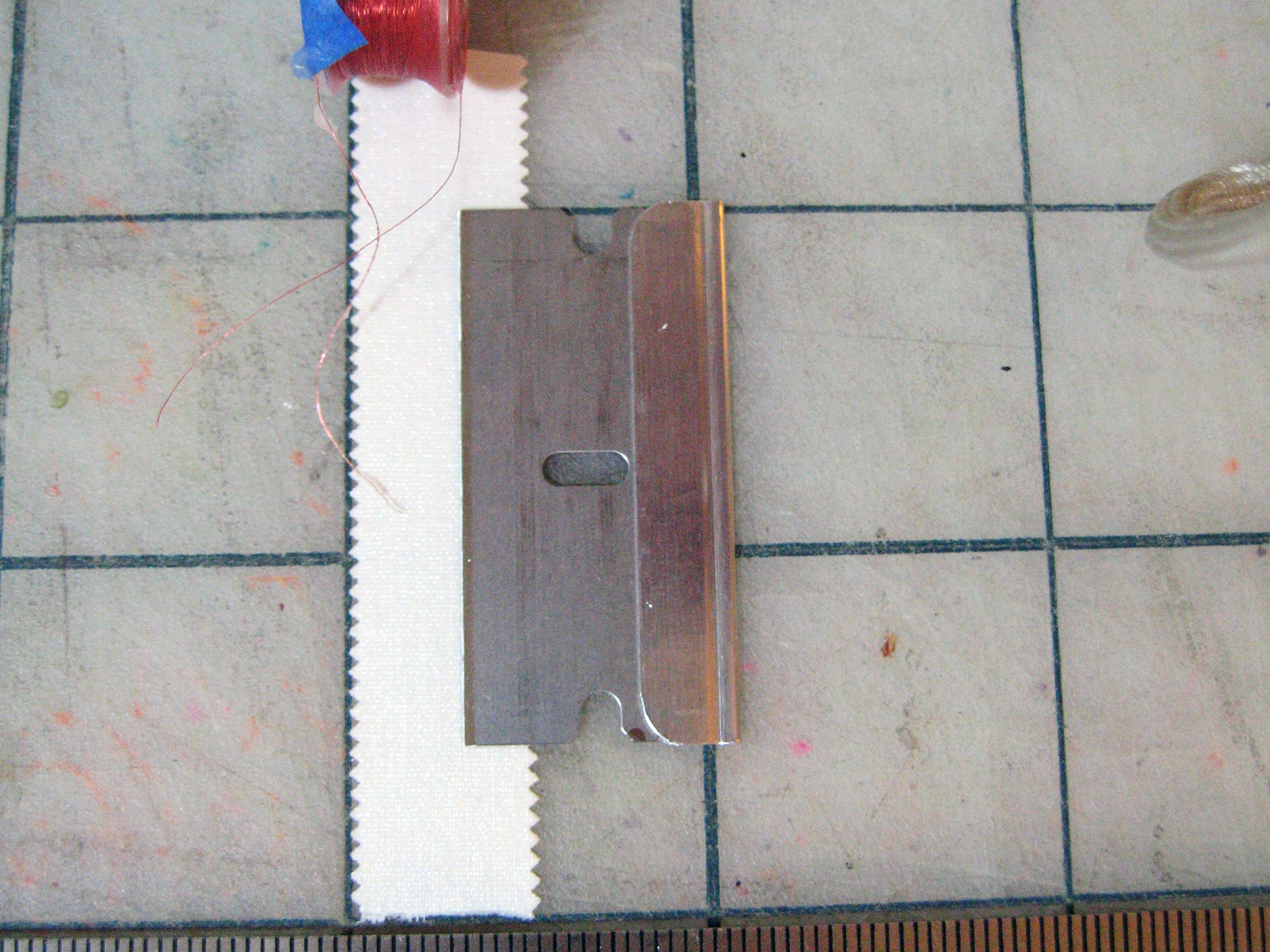

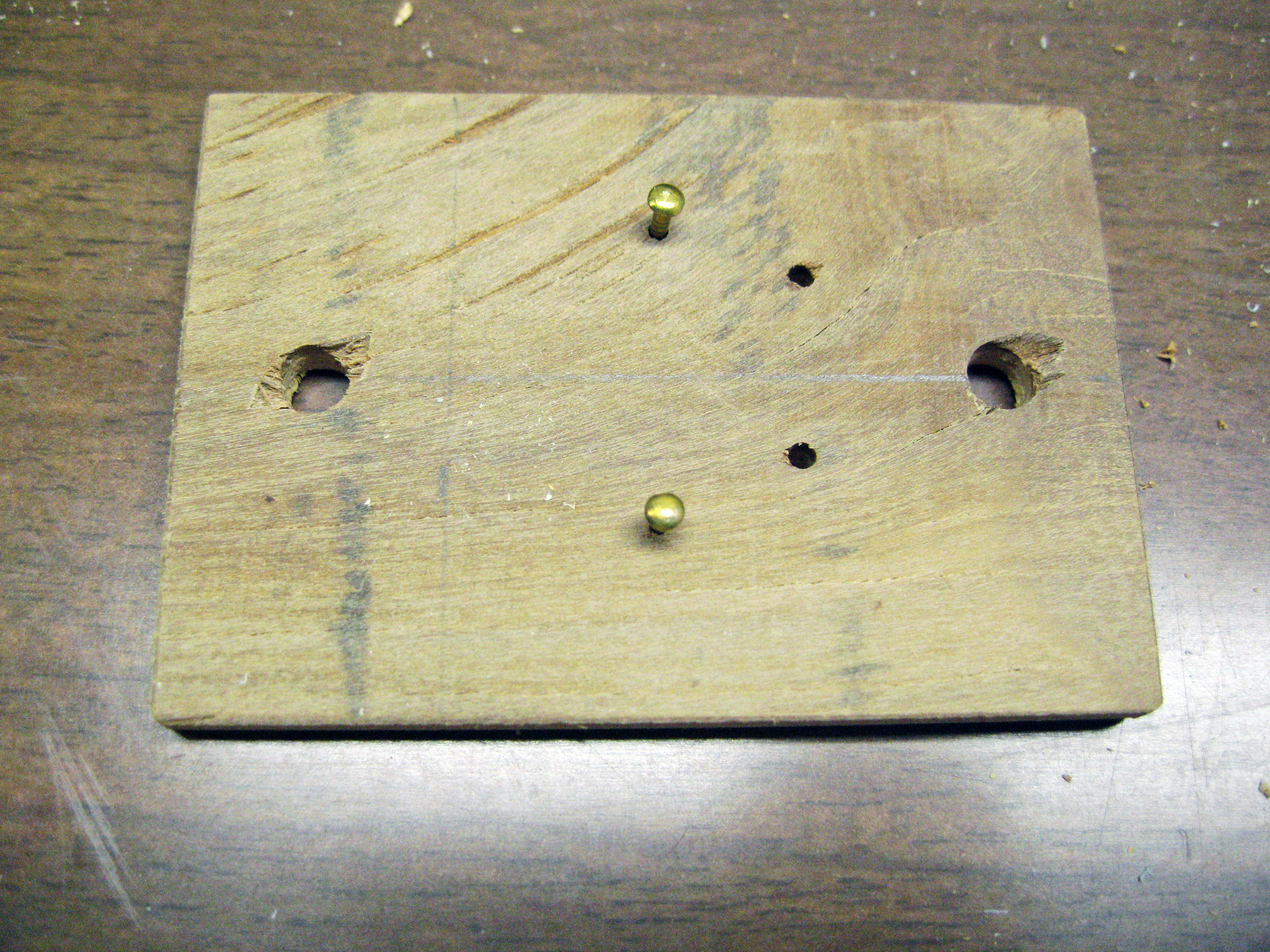

If you want to crank it up until it sounds like you really do have possession over Judgment Day, an electromagnetic pickup is the way to go. In this article, I describe how to wind your own electromagnetic guitar pickups on sewing machine bobbins.