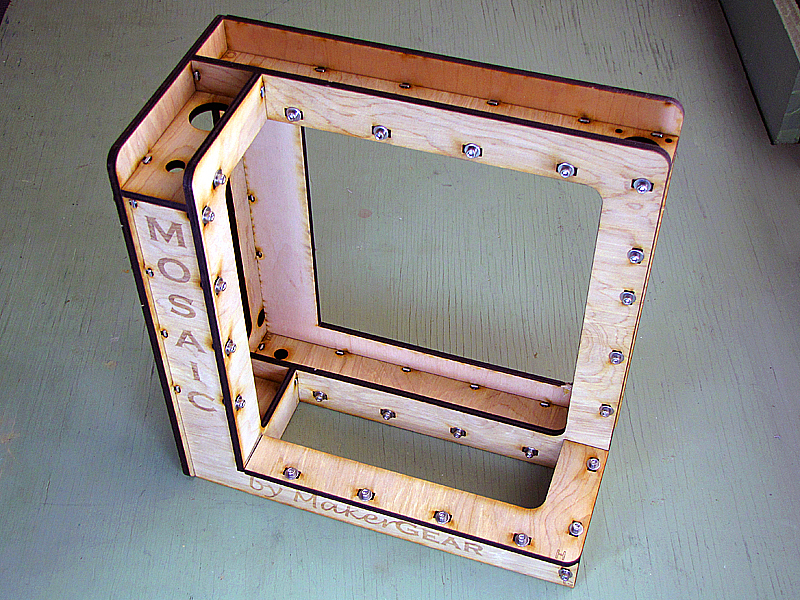

This is the first of an eight-part series documenting my build of MakerGear’s Mosaic desktop FDM/FFF 3D printer kit.

- the frame

- the Y-axis

- the X-axis

- the Z-axis

- the extruder

- the build platform

- the electronics

- the first print

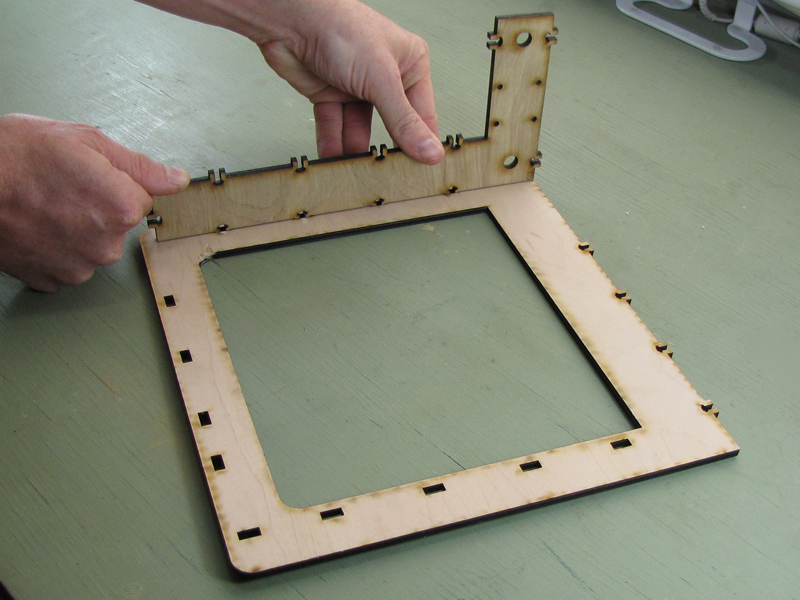

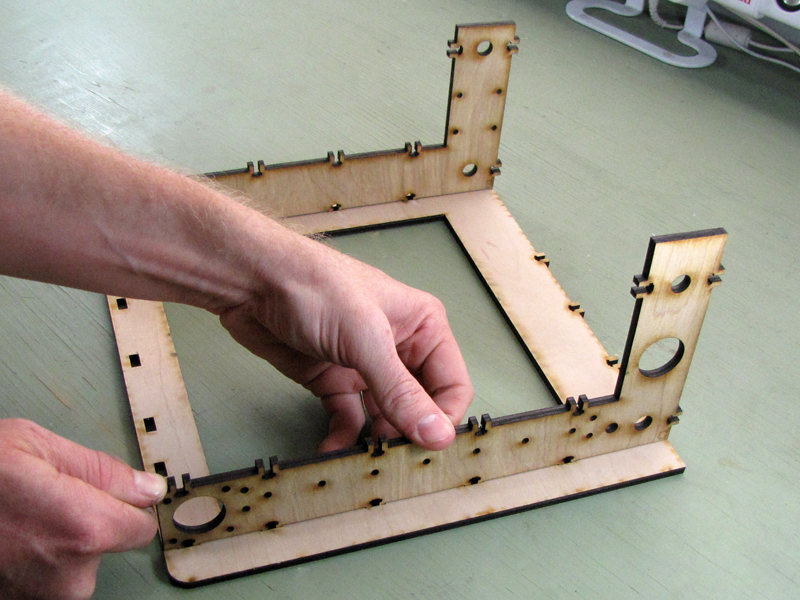

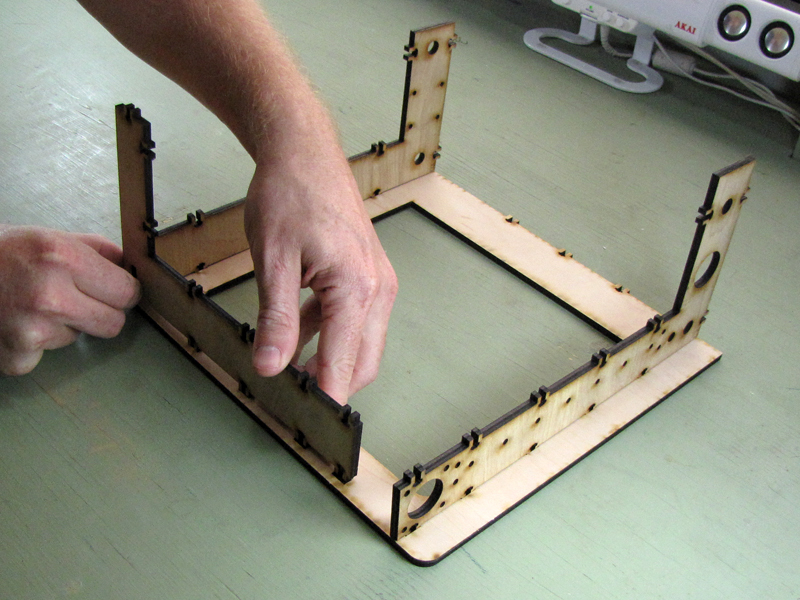

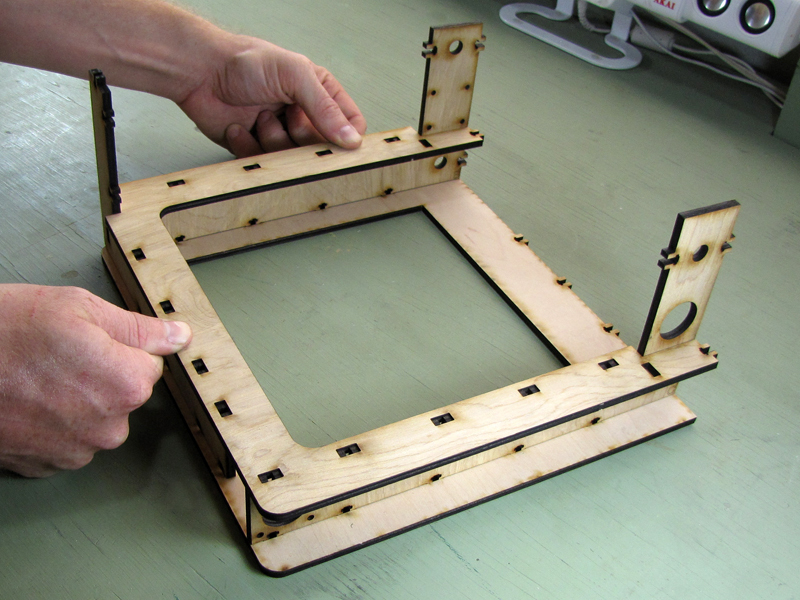

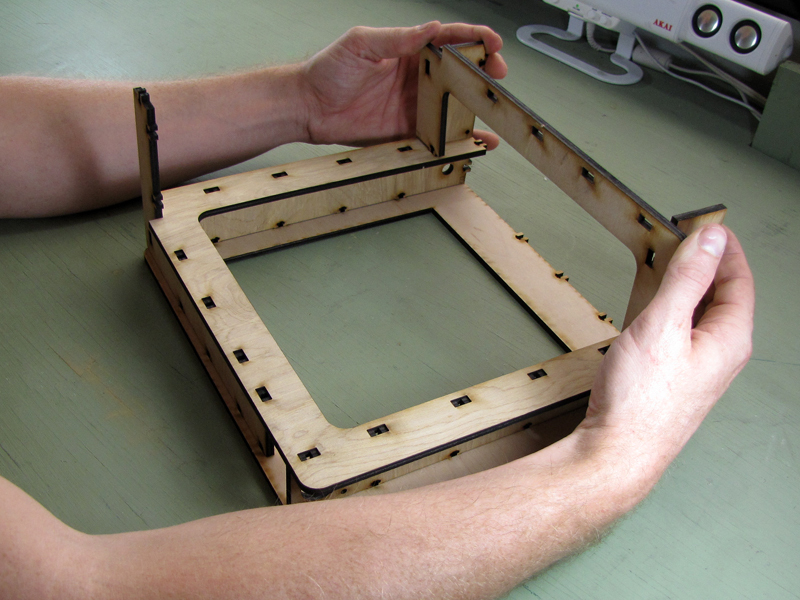

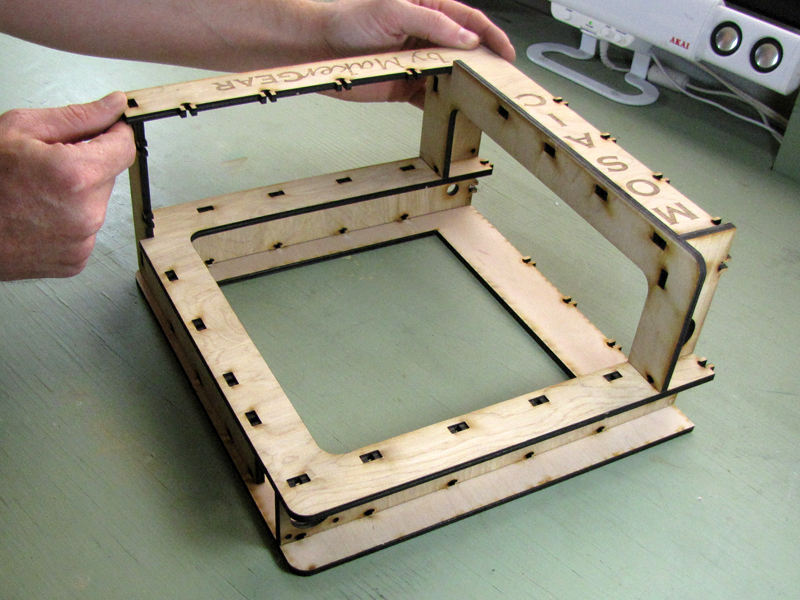

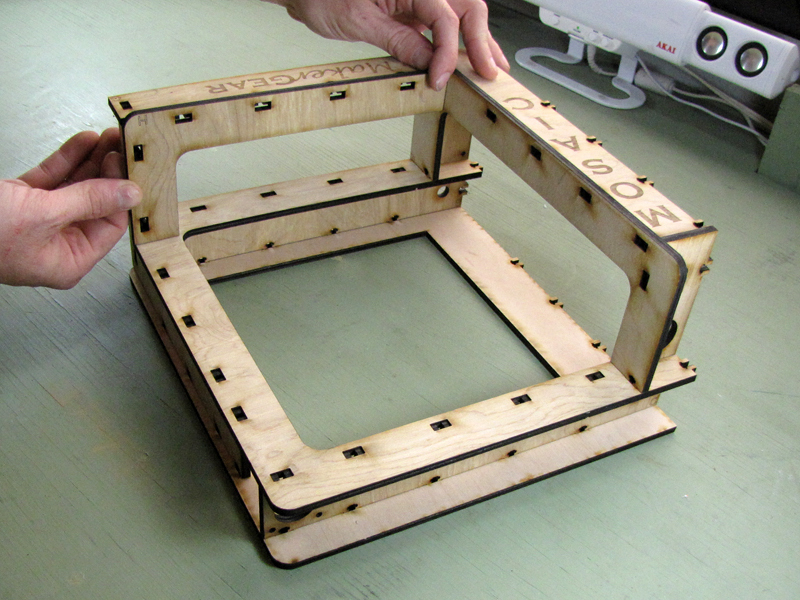

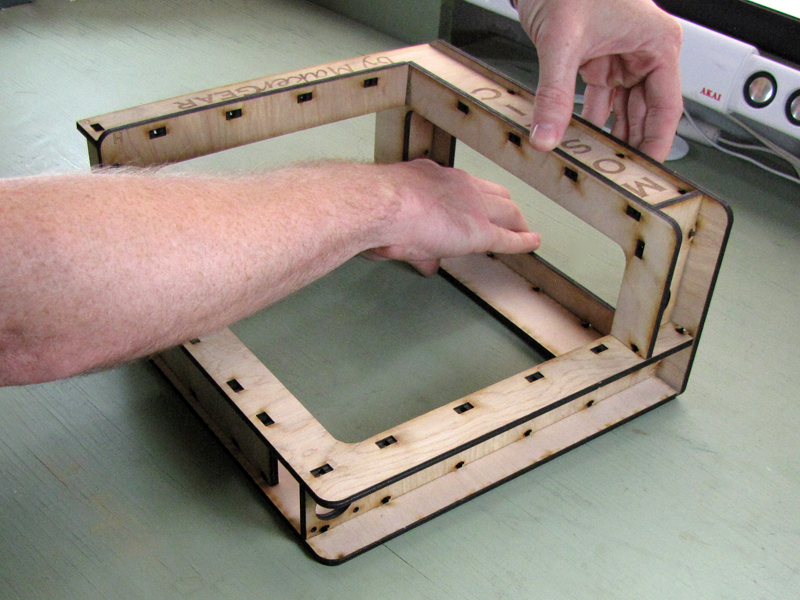

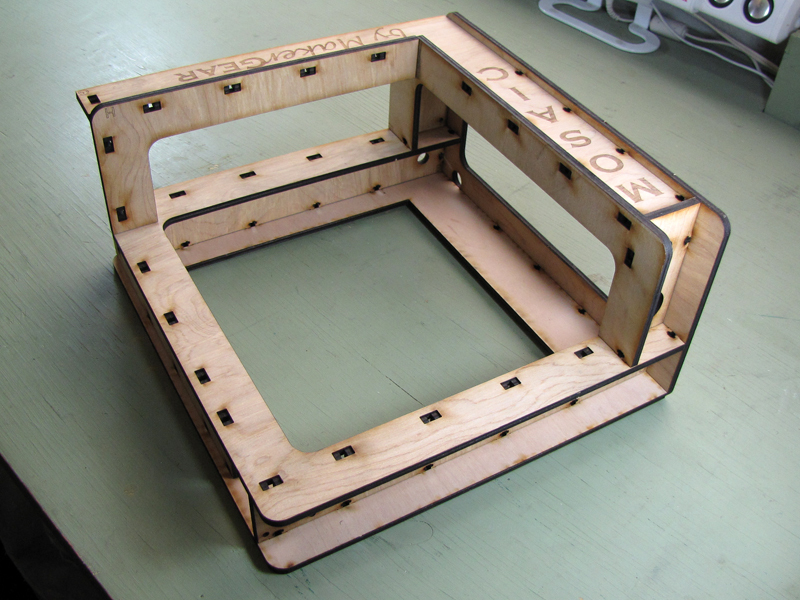

This part covers the assembly of the nine sections of the frame, which are laser-cut from 0.200″ plywood, and the method for securing them using the built-in captive-nut mortise-and-tenon joints.

Note: Many builders prefer to insert captive nuts in the frame sections before slotting them together, and, if necessary, to secure them temporarily with tape. In my build, neither measure proved strictly necessary. Using small flat-nose pliers, I didn’t have any problem putting the nuts in place after everything was slotted together. I also found that the nuts fit snugly enough that no tape would’ve been necessary to hold them if I’d decided to insert them before assembly. But your own experience and preferences may of course differ, and it’s worth thinking about before you get started.