Traction is all about digging into the terrain. When the ground is covered in snow and ice, rubber just doesn’t cut it anymore. Studded tires can really improve your bike commute in the winter months or allow you the adventure of off-road riding in winter months. The addition of transverse chains on the rear wheel can create a little more off-road traction in both icy and snowy conditions. However, while the right studs will work fine on pavement, chains can slip the rear wheel right out from under you.

I built these chains for a 26″ bicycle with v-brakes and 2″-wide tires. It should be easy enough to modify the chain design for larger 29″ tires or thinner/wider tires, although I haven’t tested other combinations. Disk brakes, internal brakes, or removing the rear brakes should also make things much easier.

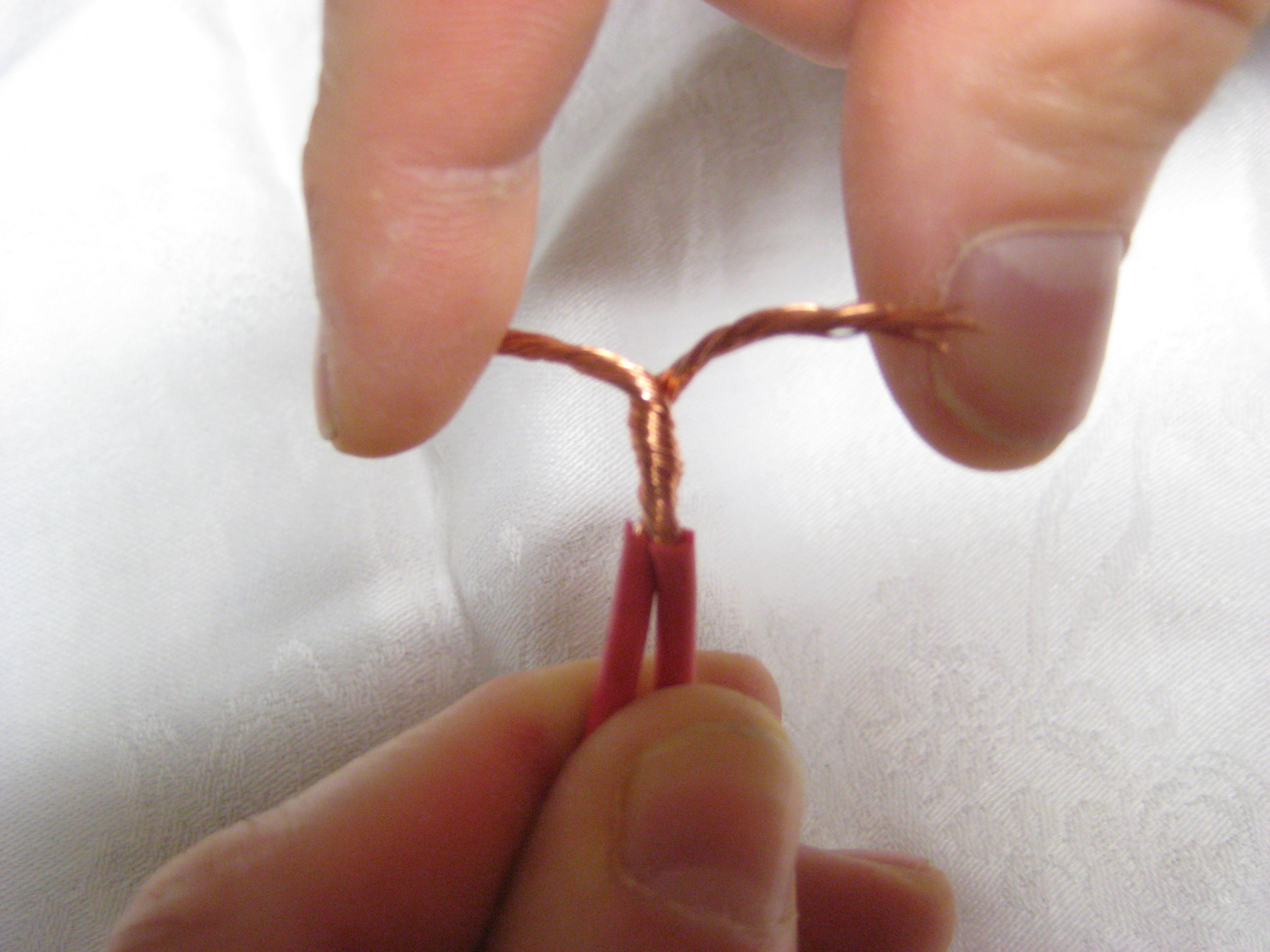

.|.