Recently I switched careers from designing industrial food and dairy equipment to teaching industrial technology in a high school. While planning this move and taking night classes, I read quite a bit about authentic instruction where the students engage in real projects that end with something tangible and with real criteria for success. With the exception of the hero teachers from the stories I read like Underwater Dreams, high schools were apparently still full of worksheets, sitting still, being quiet, and pointless drudgery. I started this job with a commitment to myself that my classes wouldn’t be like that. Giving students the freedom to fail and grow on their own with an exciting project would motivate them to do great things, right?

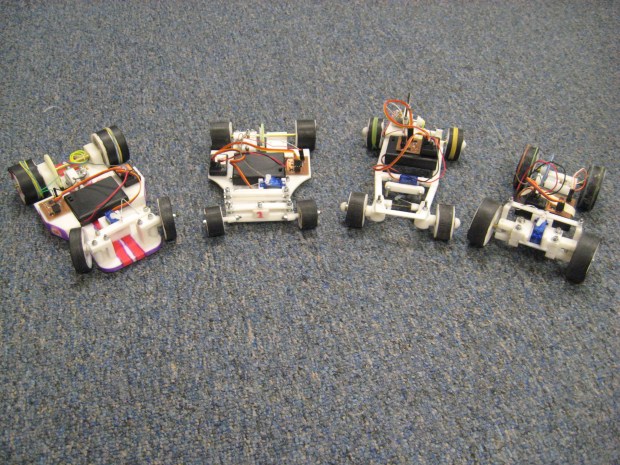

I knew the school where I was going to start teaching had a 3D printer in my Computer Aided Drafting classroom, and having some previous experience with radio-controlled cars I decided that we should design and build our own cars, then race them. Who wouldn’t be into that? There is plenty of room for innovation but the idea is familiar enough that there is a bank of prior knowledge to help the students get started. Surely these students’ competitive nature would drive them to be the best they could be. It turns out that there were a lot of things I didn’t know about high schoolers though, and here’s how things went down for me.

Lessons Learned

Task Avoidance is engrained

One of the first realizations that I had was that high schoolers are mostly motivated by not working. Left to their own devices (pun intended), the vast majority will look at the internet given the option between that and any other thing that’s allowed in the classroom. Task avoidance is so engrained by high school that they will avoid things they would otherwise pay to do strictly out of habit. I played videos of R/C car races and hounded them for action on a daily basis, and very slowly we worked through this phase and as we approached race day the students were coming in before and after school to work on their cars. The takeaway from this is that the beginning of this lesson needs a sub-goal; a way of having a quick payoff for effort that is near-term and achievable. Additionally, even though the overall project is very open-ended, high school students need structure in terms of time management, file management, materials organization, and teamwork.

Tangible objects yield informed decisions

It also became clear that the students weren’t able to start thinking critically about design decisions until the first versions of their cars had been modeled and printed. By this time they may have been getting a little better at thinking about their car, but I believe it was the new ability to see something physical, to hold something in their hands and move it around that enabled them to start making informed decisions about their designs, and indeed at this point arguments started popping up about who had the best solutions to their various problems. As a teacher, this was the best part. I held my tongue and watched them debate the pros and cons of each other’s ideas, and enjoyed the process of watching them decide on a solution. High school students have a difficult time thinking in the abstract about ideas they have no experience with, and in the future I intend to have a variety of cheap radio-controlled cars for them to disassemble and play with before they begin their designs.

Decide constraints before design process starts

As a group they had a very hard time delegating tasks, and most teams gravitated towards one student doing most of the work while the other students watched or just looked at the internet. As the project wore on, the students who were not assertive were pushed to the sidelines and lost ownership of the design, and it was difficult to bring them back into the fold in an authentic way by the very end. Students who were good designers were not necessarily good leaders, but those students ended up being in leadership positions because few other students were willing or able to offer input on the design of the car. Students had trouble deciding on constraints so that two students could work on mating parts at the same time. I asked one idle student to work on a steering knuckle but he said he needed to know the wheel diameter before he could start. I asked the student who was working on the wheel what his diameter was going to be, but he informed me that he wouldn’t know until his design was complete. I never was able to get that student to commit to a diameter before the design was finished, and the steering knuckle kid had to wait. In the future I will make a design requirement that the cars must break apart in the middle, and divide the teams onto front half and rear half sub-teams. This will force more students to have ownership in the design of the car and require them to commit to design constraints before the design process even starts.

Have a file structure and shared drive space

Some of the stumbling blocks in this lesson were me misjudging what high school students know and how they would handle this project, but others were just plain screw-ups on my part. I failed to have shared drive space available on our network so that students could create and edit Inventor files in one place. We used flash drives and Google Drive, but both were far from optimal. Also, when I was working in industry we made one drawing with multiple sheets for a project, so that is what I asked the students to do for their team’s final drawing turn-in package. However, one drawing means one file, which means only one student can open and dimension the drawings at a time. I also did not give these students as much structure as I should have, and a big part of that was that I really didn’t know what this lesson was going to look like until we were in the middle of it (like the student designing the wheel, I guess). As a drafter it would be a red flag if my employer told me that they didn’t have a file structure in place for drawing management and just do whatever works for me, but that is exactly what I told these kids, and they suffered for it.

This project was a great learning exercise for both the students and me. Overall everything went as well as I had envisioned; I just ended up having to work a lot harder than I expected for it. My students generally had a great time once they were rolling, and this lesson was probably a better picture of what real life will look like after graduation than anything else they have done in high school. On race day we invited the principals down to watch, and even though I designed and built an awesome car myself, they crushed me on the track. They all had a good laugh that Mr. Z was the loser, but being soundly beaten by my students that day couldn’t have been a bigger win for me.

Knowing what I know now, in the future I plan to implement all of the improvements to this lesson that I’ve discussed and invite some regional high schools to compete against us in a race. My total cost per team was only $50 in supplies, and only $18 of that was consumables, so next time I teach this lesson I should be able to do it for $18 per team. This is a great competitive project for a school that has a 3D printer but can’t afford to take part in an organized robotics competition.

Rules:

- Cars must be no more than 8″ long, 7″ wide, and 5″ tall.

- Tires cannot be made of anything that was designed to be a tire.

- Racetrack is on basketball court, and is made of long straights and short twisty curves.

- Motor, radio, servo, battery holder, speed controller, brass bushings, 3mm threaded rod, 3mm nuts, 3mm washers, 4mm washers, ¼” aluminum tubing, and rubber bands are provided. Any additional materials must be purchased from the team’s $3 budget, except for parts printed on a 3D printer or resin casted.

What worked for us, and what didn’t:

Tires: We used mountain bike inner tubes cut into bands for tires, stretched over 3D printed wheels. This gives some traction, but it’s not awesome. Some students put rubber bands under or over their inner tubes. I would like to try Ninjaflex filament to see if we could print better tires with it. Ideally I would resin cast silicone tires, but time and budget didn’t allow it at this point.

Suspension: I pretty much banned suspension setups because my students were having a hard enough time just getting 4 wheels stuck together on a frame. Without exception though, our frames warped slightly on the printer, and there was always a wheel in the air, which made steering with our poor traction tires all the worse. Finding a way to keep all wheels on the ground is crucial, even on a flat basketball court. Cheap clicker pens have lightweight springs that just fit over 3mm rod, and this seems like a great resource.

Gearing: We bought some gears and planned on making resin casted copies of them, but it turns out that 3D printing small drive pulleys and using rubber bands works really well. It’s easy to make multiple pulleys on the same part and move the rubber band back and forth (like the speed control of a drill press) to fine tune the gearing too. I’m not sure how efficient they are, but they work great and are super easy. A good gear ratio starting point is to have nearly as small a pulley as you can print on the motor shaft and just under the same diameter as the wheels on the drive shaft.

Press fitting: We struggled with 3D printing parts that could be reliably and repeatedly press fit onto shafts. We ended up mostly making a light press fit, and feeding a small rubber band through the hole before we pushed the shaft through for friction, then cutting the rubber band that overhung the 3D part off with a blade.

Speed Controller: I made my own speed controller from scratch using a Picaxe microcontroller and a DRV8833 motor driver chip. You can buy “320 Amp” ESC speed controllers for less than $10 on eBay that would probably work just as well, but they are quite a bit heavier.

Differentials: I attempted to 3D print a ball differential for my car using BBs, but it was difficult and wasn’t very smooth. My students mostly made solid axle drives for their cars, driving both rear wheels at the same speed all the time. This made our poor traction situation even worse. Some teams drove just one of their two rear wheels, but this made the car difficult to turn towards the driven side, and their cars would easily spin out when turning to the non-driven side. My car had a single rear wheel in the middle, and this easily worked the best for turning and for not having a suspension, but it suffered in straight-line traction.

Bushings: We used K&S brass metric tubes for our bushings. The 4mm fits just inside the 5mm, and the 3mm fits just inside the 4mm. It worked really well, but the fit is so close that if you have two co-linear 5mm sections with a single 4mm shaft going through them they will bind and cause excessive friction. It’s almost impossible to get both 5mm sections perfectly in alignment. Every team struggled with this problem. I may buy cheap 4mm inner diameter bearings in bulk for the next time I teach this, but we were able to modify our designs so that our drive axles only passed through a single bushing tube, and it worked well.

Bolts: We used nylon insert 3mm nuts from McMaster Carr on both ends of a cut piece of threaded rod instead of bolts. We used red Loctite on one end. If you 3D print a hexagon recession into one of the two parts you are bolting together you won’t need a wrench on that side.

Motors: We used the Pololu 130 Size 3v brushed 17kRPM, 3.6A stall motor (Part number: 1592), and at $1.59 each (+5 quantity) they are a really good buy. We absolutely destroyed them though, running them at greater than 4.8v, and they had a life span of only a few days of abuse. You need to solder capacitors to the motor connections to prevent radio interference too, and I spent a lot of time desoldering capacitors from dead motors and soldering them back onto new motors. I would recommend spending a few more bucks on a carbon brushed motor, maybe a Tamiya Dash series 130 motor. I am currently trying to find cheap replacement carbon brushes for 130 size motors so I can upgrade the cheap ones I’m already using.

Servos: We used Hextronik HXT500 servos and they worked well until a hard crash when the steering linkage breaks the teeth off of the gears. This could have been prevented with bumpers or by bending an angle in the paperclip wire linkage so that the wire would bend before it damaged the servo.

Batteries: We used four NiMH AAA batteries per car because I already had a charger for them. The output voltage is perfect for the receiver and servo, and gives good power to our 3v motors, although with a shortened life.

Parts List:

As I think back, that $7 for the speed controller may be a bit optimistic. I may have $10 in that.

ADVERTISEMENT