Ceramics are an ancient material, but we think of them as high-tech when it comes to 3D printing. However, as with many 3D printing techniques, what used to be a high-tech industrial process is starting to become accessible to the garage enthusiast. And if you’re already creating and firing ceramic pieces, you may have a lot of what you need already.

There are two fundamental types of 3D printable ceramics. In one case, clay is directly printed with a special-purpose paste printer. In the other, you print “ceramic” filament with clay particles embedded in a plastic carrier or binder, and you need to “debind” out the plastic before firing the piece. There is also a (challenging) resin printer version of this latter method.

In all these scenarios, a standard kiln will work for the firing stage. This is in distinction to the metal-infused filaments we described in our piece in Make: Volume 86, “Lower Cost Metal 3D Printing.” Those require a higher-tech furnace with tight control of temperature for sintering, and often vacuum or an inert gas during some of the process. For these ceramic applications, the kiln just has to reach high enough temperatures with a controlled profile. For all the options described in this article you can learn more about firing on the company’s websites.

Design issues with printed ceramics are similar to those with metal filament, like allowing for shrinkage during debinding and sintering. For some materials, gravity will make the vertical, z-axis direction shrink a bit more than the other two, but this is not universal.

CLAY 3D PRINTERS

Let’s talk first about directly printing in clay, which stays pretty soft out of the printer. This type of printable ceramic can be worked with like any other clay, adapted a bit by hand if desired, and then fired in a kiln. Italian 3D printer manufacturer WASP sells its Delta WASP 2040 Clay printer (Figure A) for €3,300 ($3,588), and the larger 40100 model for €7,590 ($8,252). This method of printing clay also requires a compressed air supply; you’ll need an 8 bar (116psi) compressor with a 50 liter (13gal) tank. European compressor options are specified at WASP’s technical specs pages.

These delta printers are aimed at the market for creating larger ceramic pieces (Figures B and C) — the 2040 model can print parts up to 20cm in diameter and 40cm high, and the 40100 can handle 40cm diameter by 1 meter high. The main negative to this approach is buying a special-purpose printer, though it is also possible to buy clay retrofit kits for WASP’s more general-purpose deltabot 3D printers.

Obviously you aren’t going to buy a specialized clay 3D printer unless you are thinking about doing a lot of this sort of thing. However, if that is your intent, the material for this printer is vastly cheaper than clay-infused filament. Red earthenware clay is €15 for 12.5kg, or a little over €1 per kg. Other materials will vary in price, and shipping from Italy will need to be factored in for customers on other continents.

WASP has online courses available in English and Italian to get you started with clay. The products created are fired in the usual way for this type of clay, without the requirement for specialized kilns. One plus is that since it is soft coming off the printer, some traditional clayworking and smoothing can be done before firing. Prints will also shrink a bit during firing; how much will depend on a variety of conditions.

There are several other entrants in this space, like 3D Potter in Florida, VormVrij in the Netherlands, and Stoneflower in Germany. It’s a dynamic market, so if you’re thinking about a purchase, do a bit of reading reviews and considering shipping costs and material availability in your tradeoffs.

CERAMIC-INFUSED FILAMENT

An alternative method is to use a ceramic-infused filament, and then bake out the plastic carrier after printing. The tradeoff here is that you don’t have to buy a specialized 3D printer, but the material is considerably pricier than the bulk clay used by paste-style printers. These ceramic filaments are also going to be abrasive, so swapping a hardened nozzle into your printer is a must.

There are various materials emerging in this market. Some are aimed at specialized engineering markets that want to create delicate parts with particular properties that can’t really be formed with conventional techniques. Others are designed to work with a low-end consumer 3D printer, and then baked out in a (temperature-controllable) ceramic kiln. Needless to say, parts will shrink substantially as the binder bakes out or is removed chemically, although the manufacturers say that the shrinkage is fairly symmetrical on all axes.

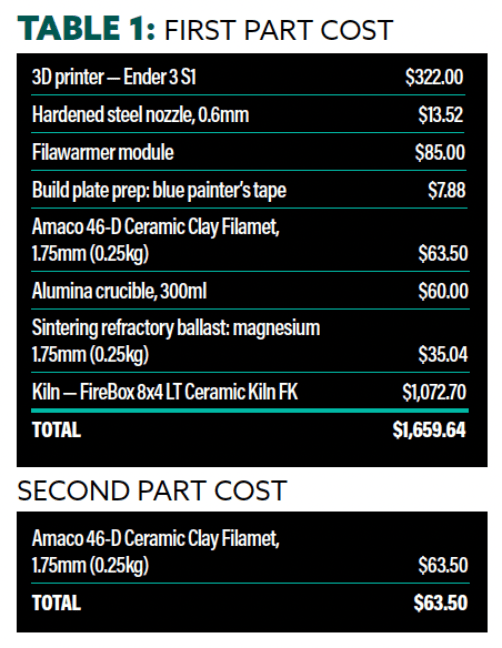

The Virtual Foundry has a product called Ceramic Clay Filamet that works this way. It does not require any separate debinding chemicals, just a heat-debinding process and then firing in a kiln. Here are costs (including a basic 3D printer) from Virtual Foundry for what it would take to get started printing clay (Table 1). They also have a Filamet version of Pyrex (borosilicate) glass.

Part feature size (print resolution) is consistent with what you would expect from a consumer 3D printer. The parts shown in Figure D are made of 46D zirconium silicate and silicon carbide. In Figure E we see a sintered 46D part perched on an unsintered part of the same material; the sintered (lighter) piece is about 2″ across at the base. The company notes that it is relatively easy for them to make customized mixes if a customer needs something unique.

French ceramics manufacturer Nanoe has several types of ceramic-infused filament — white and black zirconia, silicon carbide, and alumina — which it sells under its Zetamix brand. These are mainly intended for the specialty technical ceramic market, costing in the €200–€400 range for half a kilogram, with interesting dielectric or other properties.

The Zetamix debinding process requires soaking the part in acetone as a first step, which removes some of the binder. Then, after the acetone has been allowed to evaporate from the part, the remaining binder is baked out in the kiln. Since acetone is flammable, this process requires careful attention to the manufacturer’s process and knowledge about how to safely ventilate and manage acetone around a kiln. The Zetamix website has extensive documentation for each material on design limitations and process guidelines.

PORCELAIN FILAMENT

Nanoe’s newest entry in the line is a filament that can be used to create porcelain parts, Zetamix Porcelain. Porcelain is denser than other ceramics and less porous. Traditionally made with a high proportion of kaolin clay, it can be made thin and translucent. Porcelain has been used for centuries to make elegant, thin, but watertight pieces like fine teacups. It also holds paint and glazes well.

While still pricey at €99 for a 500g spool (Figure F), the porcelain filament does not require buying a specialized printer or kiln beyond what one would otherwise use for these ceramics. Parts will, however, shrink more in the z (vertical) axis than the horizontal ones; it’s recommended to print them at 116% scale in x and y, and 136% in the z axis.

After bake-out steps like those for the other Zetamix ceramics, the porcelain can be glazed and fired (Figures G and H) which will largely fill in the layer lines, leaving a fine surface (with, of course, some texture remaining). This is a new area for experimentation, ripe for finding innovative ways to mix new and old techniques.

CERAMIC RESIN

Rounding out the options for consumer-level printing of ceramics are resin ceramics, although admittedly this option may be challenging for most. Formlabs has a technical ceramic resin, Alumina 4N (Figure I), available only for use on its Form 3+ printer; it requires a compatible build platform and tank as well. The intended use cases are high-temperature, high-strength, intricate engineering parts that would be difficult to fabricate in other ways, and that can withstand corrosive environments. As always, resin printers shine for tiny parts requiring fine features.

At $1,299 for a liter, this resin is not intended for hobbyist use. (In fact, the Formlabs store page for Alumina 4N makes you check a box acknowledging that you will need more equipment and experience before it lets you put it in your cart.) The resin has ceramic particles mixed into it, which is obviously challenging for a technology that relies on illuminating resin to cure it. The abrasiveness is problematic as well, since SLA printers need to keep their trays clear and free of scratches to perform well. Bottom line: not for SLA printer beginners.

In addition, parts printed with this material have to be washed in a unique Ceramic Wash Solution since they will crack in the usual isopropyl alcohol used for cleaning, or for that matter, in water. Then parts must be thoroughly dried and then fired. Formlabs predicts shrinkage of 22% in the horizontal plane and 26% in the vertical. If you’re thinking about it and own a printer, read Formlabs’ documentation of the process and printer settings before embarking. And of course you’ll need to obtain a kiln capable of maintaining the required temperature profiles.

If you are very experienced and have a compatible Form 3+, and you need a technical part that can’t be formulated with one of the other ceramic techniques we’ve discussed to this point, this might be your only 3D printing option.

GOING REALLY BIG

Now that we’ve progressed from direct-printing pieces on the order of half a meter tall down through delicate technical pieces, let’s consider what happens if you want to create something on the scale of a house. Creating adobe and brick dwellings is arguably the oldest additive manufacturing, and you might ask whether ceramic printing techniques can scale up to create house-sized objects.

Printer company WASP, mentioned earlier in this article, has created an experimental 3D printer (Figure J) to create buildings out of locally available materials, like one they have dubbed their Gaia house (Figure K). Their goal was to use readily available soil, lime, and waste fiber from agriculture, converted into building materials. They have since gone on to accept building challenges in other materials, and it will be interesting to see whether concrete or clay-like 3D printing eventually wins out in this space.

THE BOTTOM LINE

3D printing ceramics with consumer-level equipment is not only possible, but a vibrant space with a growing number of competitors. We have given a representative sampling here, but if you have an application you want to try, you should do a bit more searching to see which of these options makes sense for you.

From an economic point of view, if you imagine yourself doing a lot of parts and extremely fine detail is less critical, a special-purpose paste printer is probably the way to go. The material will be cheaper than filament by one or two orders of magnitude, and it may be easier to do your own material experimentation. You’ll need to invest in a printer, kiln, and peripheral equipment like a compressed-air source.

Filament lets you get started more cheaply, particularly if you already have a suitable printer (with a hardened nozzle) and kiln. What type of filament you use will be driven by the precise material you want, and what type of debinding and post-processing you feel comfortable doing.

Resin ceramic printing is likely to remain the domain of industrial applications for a while, although one never knows in 3D printing when something innovative will come down the pike.

And of course we hope that our friends at WASP are indeed at the forefront of a trend to build substantial, attractive housing with local materials where people might otherwise be in tin-roofed shacks at best. We hope to hear more innovative applications of ceramic 3D printing at all scales in the near future.

This article appeared in Make: Volume 88.

ADVERTISEMENT