It is fairly common knowledge in the 3D printing community that some materials produce additional wear on your nozzle. E3D, the makers of a fairly popular series of hot-ends for 3D printers, has taken an in-depth look at the effects of printing with abrasive materials, specifically ColorFabb XT-CF20.

They started out by inspecting the current nozzles they had in use. These nozzles have been printing large quantities of standard materials (PLA, ABS, etc.) for some time.

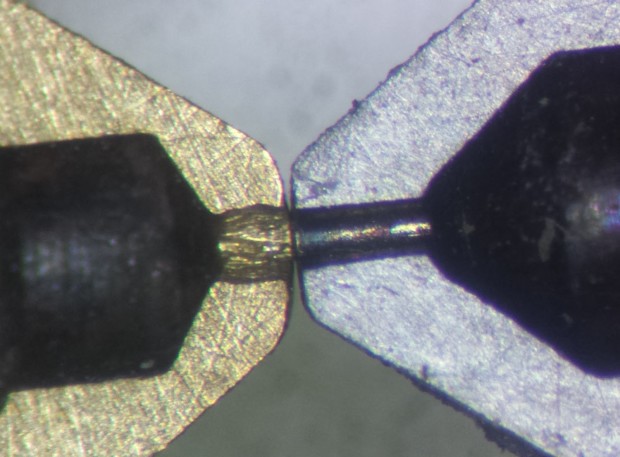

They then sacrificed a brand new nozzle, printing 250g of ColorFabb XT-CF20 carbon fiber filament. As you can see in the image below, there is considerable wear.

This not only looks ugly, but it can affect your print quality pretty easily. The shape and texture of this cavity can cause changes to how the filament flows and the fact that the nozzle is no longer the exact diameter that the software expects will cause your prints to suffer.

Being a company that makes nozzles, E3D now offers a new nozzle that can take this kind of abuse. The new nozzle is heat treated steel that is considerably more resistant than the old brass nozzles .

The nozzle on the right in the image above has printed 10x the amount of the abrasive material that was put through the one on the left. 2.5kg total of ColorFabb XT-CF20 were pushed through the new one and it shows practically no wear. These new hardened nozzles are available in their store right now.

Go to their site for more information, pictures, and more detail on how they tested, and the results of their tests.

5 thoughts on “Detailed Breakdown: How Carbon Fiber Filament Ruins 3D Printer Nozzles”

Comments are closed.

ADVERTISEMENT

Join Make: Community Today

I don’t know much about 3D printing, is there a reason they didn’t go with a ceramic nozzle? seems to me that if abrasion is the issue ceramics would offer the most resistance, and I’d guess at a lower cost per unit as well.

because ceramic is an insulator, and the nozzle needs to be 230 degrees(ish) celcius

Titanium perhaps?

my mate’s aunt makes $98 consistently on the PC………After earning an average of 19952 Dollars monthly,I’m finally getting 98 Dollars an hour,just working 4-5 hours daily online….It’s time to take some action and you can join it too.It is simple,dedicated and easy way to get rich.Three weeks from now you will wishyou have started today – I promise!!….HERE I STARTED-TAKE A LOOK AT……vp

➤➤➤➤ http://GoogleSpecialGreatJobsReportsCenter/$98hourlywork…. ⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛⚛

And once you discover that their charging over 20 times the price for a single nozzle that x10 times the amount put through a standard nozzle doesn’t seem to matter much anymore.

Here’s the cost comparison

20- 0.3mm brass nozzles @ $15.00

1 – Hardened steel nozzle @ $22.00