There was a time when every home 3D printer was some kind of experiment. There wasn’t a widely agreed upon layout or electronic configuration or size. Everyone was pulling info they needed from the RepRap project and kind of just winging it. Over the years, a few designs have certainly dominated the landscape and mass production has brought costs down and performance up. These are all good things.

However, though we can all agree that modern day 3D printers are amazing, many of us kind of miss seeing such a wide variety of experimentation. One person in particularly has carried on this tradition, and we’re glad he did because he’s kind of known in the community for having out-of-the-box concepts. This person is Nick Seward, a teacher of computer science at public residential high school for gifted in Arkansas.

Here’s a quick video of one of the more visually stunning designs he’s put out, just to get you in the right mindset.

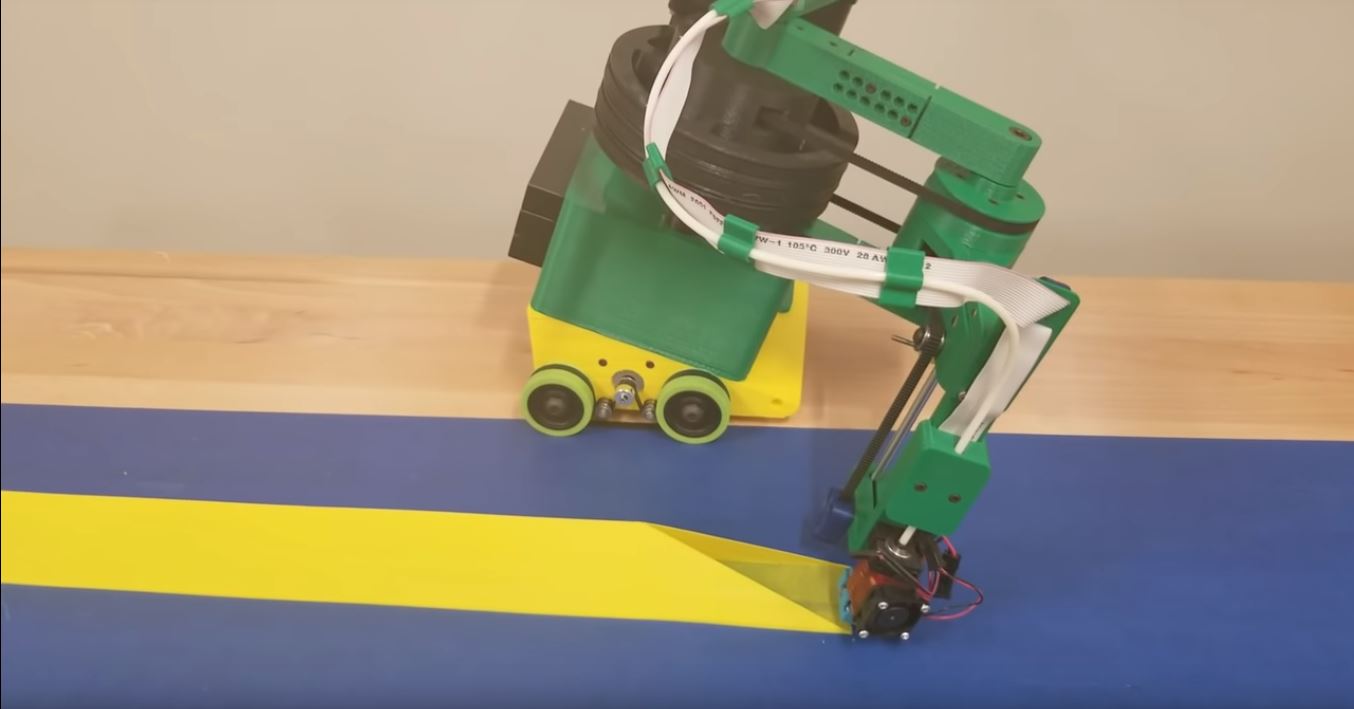

Over the weekend of the Midwest RepRap fest, I saw Nick’s name pop up again, and of course it was attached to a really cool printer. This is Wheelios, a little SCARA arm on wheels that can print indefinitely in one direction, assuming you could supply an unending spool of filament, a clear runway, and a long enough power cord.

I reached out to Nick and asked him a few questions. I was curious not only about this printer, by why he continues to make interesting new designs.

Why do you keep designing new 3d printers? (as opposed to refining a single design)

My original goal was to make a true RepRap printer. I was able to get much closer than most but some of my early efforts like Simpson and Wally needed more advanced control than I was able to supply them. The designs weren’t as easy to use as the printers then and printers have gotten even easier to use now. Simpson and Wally served their purpose. They showed me and others that it is possible to get good prints out of low cost largely 3D printed printers. Moving forward, I needed to either find a design that is easier to control or improve my ability to control them. I have been working on both fronts.

Currently, my best serious hope is RepRap HELIOS. The SCARA arm moves only in one plane make control infinitely easier than Simpson. We now have better bed leveling technology. Specifically, I use impact probing (sense when you hit the table) to characterize the surface that I am printing on. I can now load up my vanilla gcode and hit print an good accurate prints appears. I have worked through a few versions. Each of them have some problems blocking me from releasing them as is. (Releasing Simpson before I worked out the bugs was a huge time sink and I hope to avoid that in the future.)

WHEELIOS was an extension of a project I set for my students. They had already built Tablebot (see youtube) and it worked okay. One of my students wanted to do a follow up and we come up with the idea to use a HELIOS arm. I used the project as an excuse to improve the arm for HELIOS. It was actually surprising to me that it worked as well as it did.

A side goal that I now have is to make small portable printers that can print huge things. WHEELIOS can fold down into about a 10″ cube and so can HELIOS. WHEELIOS can then print stuff that is 150x150xinf. The upcoming HELIOS will be able to print in a donut region that is 700mm in diameter and at least 150mm tall. If you do the math, that is about 5 times the print volume of the Prusa and can easily fold up inside the Prusa’s print volume.

You’ve designed several interesting systems but we don’t see those designs proliferate. Why not? (thinking of simpson, and those SCARA arm systems)

When presented with a problem, most people will first look at how the problem is typically solved. That is smart. However, the optimal solution isn’t always close to an existing solution. There is a large cost (in time or money) associated with experimenting with first principal thinking. Even if these attempts result in a solution that is marginally better, they will often get discarded. It takes something much much better for people to leave the comfort of the typical.

My designs have included some interesting ideas. I even think that some of the concepts are superior to common practice. However, I don’t think I have made anything (yet) that will encourage people to endure the pain of switching over to my approach.

HELIOS and WHEELIOS could get some traction but I will need to have a very smooth release of them. If I release them with any unnecessary pain points, I might squander peoples willingness to try something atypical.

Is there anything you see on the horizon in 3d printing that has you particularly excited?

Until recently, all of my designs have used standard 3D printer control boards limited to 4 stepper channels. There are now better boards that can support a lot more and I am more capable of doing my own electronics and firmware. I have projects in the works to make a production printer that can run an unlimited number of extruders at the same time. I am building a Sextupteron (I invented it. I wrote a paper with an inventor of the tripteron but he decided it should be called a hexapteron in the paper.). Working on a nonplanar slicer that can feed the Sextupteron interesting gcode.

That is just a few of the things I am working on in the 3D printing field beyond what I have published.

In the field of 3D printing, I am very interested in the instant printing that they did at UCB. I have had some tangential ideas like this for years but they required expensive setups and control systems that didn’t exist. This approach could be much cheaper and faster than current SLA printers.

I also expect to see construction to increase their level of automation. We have plenty of examples of this but they are mostly proofs of concept. We have yet to see a company embrace a new construction technology that is disruptive to the industry. I think it is going to happen soon as we are currently seeing in manufacturing.

ADVERTISEMENT