Last week, Make:‘s Matt Stultz wrote about the new collaboration between

In March, I used 3D Hubs to print a part of my own, which served as a preview of what this collaboration could grow to provide. It was my first foray into 3D printing, and it went smoothly.

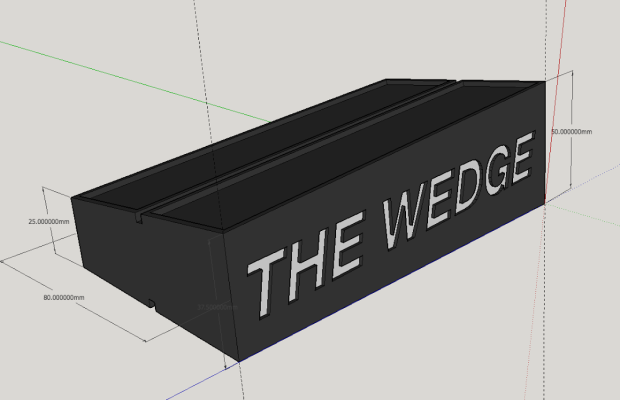

I had decided that my smartphone desk docking situation lacked a certain indulgence. Sure, traditional docks hold phones at a nice viewing angle, but they’re too steep for much practical use. Simply letting the phone rest on the desk held the phone at too shallow an angle — and in any case, it felt irreconcilably pedestrian for my handset’s incredible computing power.

Calling on my brief stint in mechanical engineering, I drafted up what amounted to a wedge-shaped brick of would-be plastic using the free CAD program SketchUp. I carefully measured (that is, awkwardly held a ruler vertically while fumbling with my phone) to determine an ergonomic pitch. I clicked, dragged, and bungled keyboard shortcuts until I had a symmetrical shape that would work on a user’s left or right side.

The 3D Hubs interface let me find just the right printer for my needs based on: Resolution (the lowest), Response Time (who cares, they’re all within 24 hours), Distance (within walking/public transportation access), Material (PLA, cheapest).

I uploaded my file to the “hub” of a man named Nick. The part warped, Nick was overly apologetic, and a pleasant representative from 3D Hubs (one is assigned to every transaction) stepped in to issue a refund.

My next order was with Evan, a Northeastern University student, and it went off without a hitch. He asked some questions about the part, I answered, and a few days later I picked it up. Throughout the quick process, Evan and I communicated via the order page and I received notifications via email any time Evan or the 3D Hubs rep chimed in.

Here’s what my smartphone dock looked like after Evan printed it:

Not everyone needs to 3D print something, but many people want to. The partnership with Thingiverse takes away the CAD learning curve that still presents a barrier for many, and puts printing just a click away for any John or Jane Doe.

“Working with 3D Hubs is a natural next step as we continue to grow our MakerBot 3D Ecosystem,” said MakerBot Chief Experience Officer Joey Neal. “At MakerBot, we are continuing to look for ways to get 3D printing into the hands of more people. 3D Hubs has built an incredible network to fulfill 3D prints locally, which we see as a natural fit for integration into the Thingiverse community.”

The partnership also encourages recognition and compensation by encouraging a gratuity that goes directly to a part’s designer. Makers looking to add the 3D Hubs button to their Thingiverse designs can sign up here.

3 thoughts on “I Used 3D Hubs to Print a Phone Dock. Here’s What Happened.”

Comments are closed.

ADVERTISEMENT

Join Make: Community Today

My library offers 3D printing for free (for now).

]

Hey George, it’s Matt (the guy who wrote the hubs article you referenced). I live in RI so the next time you need a hubs print, just send it my way :). https://www.3dhubs.com/providence/hubs/matt