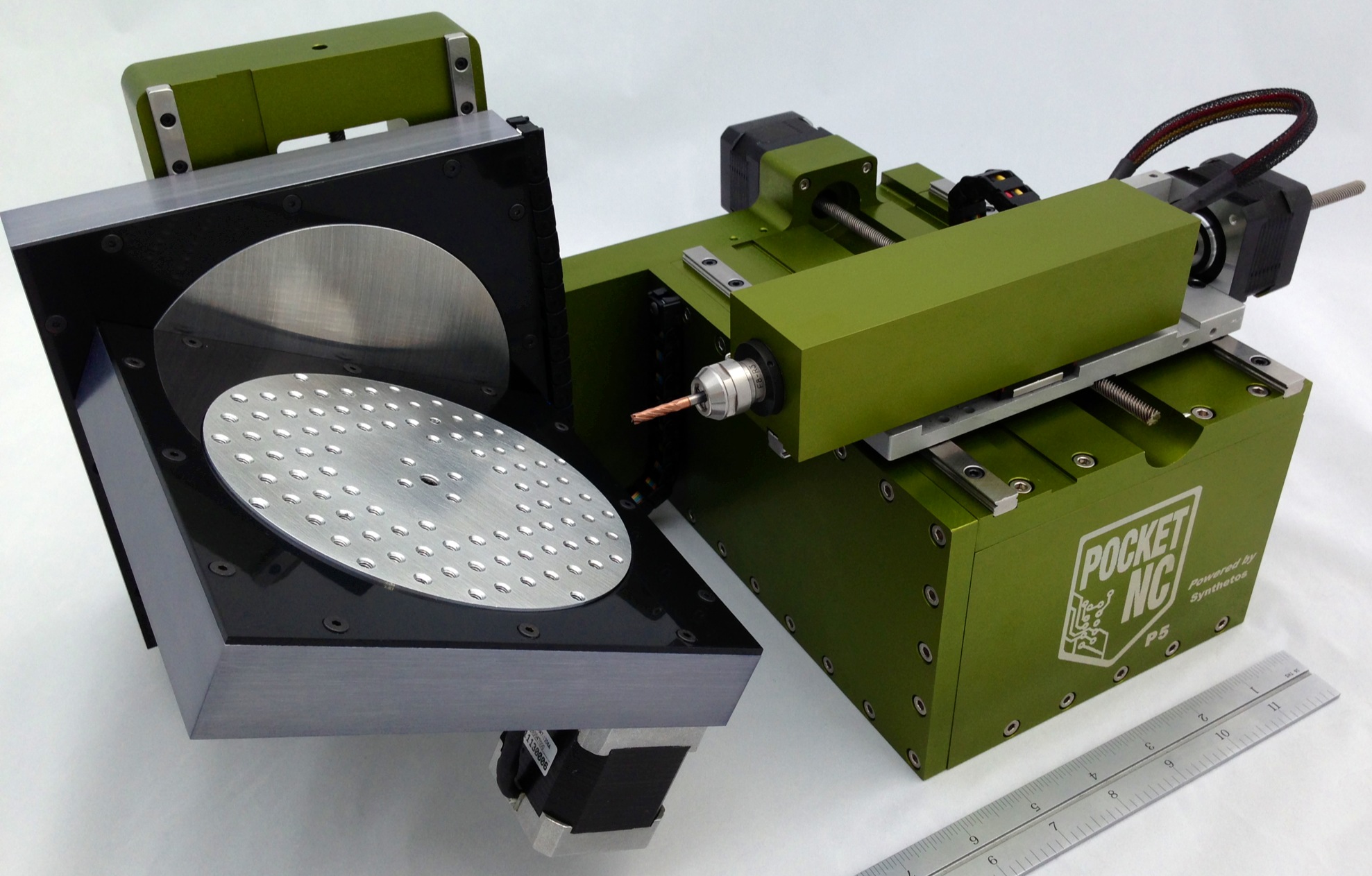

Jaws drop when makers see a five-axis CNC at work. That’s what happened to me when I saw PocketNC performing its magic. I peered closely and saw a spindle moving along two axes milling a piece of plastic mounted on a trunnion moving along/around three axes. The result of a three-year, four-prototype development effort of husband and wife team Matt and Michelle Hertel, PocketNC is getting ready for market.

Machinists and mechanical engineers, this couple loves building things. After participating in many Instructables contests and putting in up to 30 hours per week on their entries, they eventually decided to channel their energies into something which they could sell as a product. Matt had wanted a mini mill but couldn’t find what he wanted at the price he was willing to pay. Over the course of their research, they found that many others wanted the same thing so they decided to build their own but jumped straight to five-axes.

While their prototyping efforts started in the house they quickly converted a 10×10 shed to a workshop where they worked. From the start, the mill’s frame was built of aluminum but they are always working to reduce weight, presently at 25 pounds. The mill uses stepper motors and they can cut dependably to a tolerance of +/- 1/5000th of an inch, the spindle turns at 500-6000 rpm for plenty of range for speeds and feeds of various materials. The millable volume is 5″ diameter by 4″ tall. This gem can mill plastic and aluminum and they’re confirming that it can also mill steel and titanium

World Maker Faire was their first big public showing of PocketNC and they found it invigorating. After years spent working on the project in isolation it was exciting to see so many positive reactions from the maker community. They’ve come a long way after multiple prototypes. They still want to test more materials, switch their controller to Synthetos, and then go to market but with measured organic growth till they get it totally right.

Cost? They’re shooting for around $3,000.

ADVERTISEMENT